Dairy and chocolate

Blending with us shortens food processing time

In the food industry, a reliable processing of products is important. In this price driven area, stand-stills and a lot of maintenance create headache to the production and they are looking for easy to handle and highly reliable technologies.

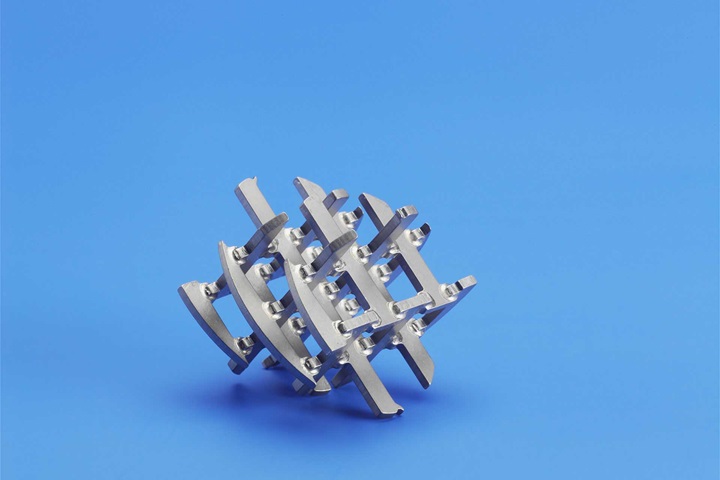

Static mixers fulfil important tasks in the food processing industry. It is particularly suitable for admixing additives such as fragrances, flavors and dyestuff, minerals, trace elements, vitamins, emulsifiers and preservatives. Pasteurization and sterilization are further important areas of application.

Our processes provides the following advantages:

- Stainless steel for hygienic processing

- Motionless for maintenance free production

- Static sealing to prevent contamination

- Easy cleanable CIP/SIP

- Small volumes

- Minimum waste

- Energy saving

- Fast production

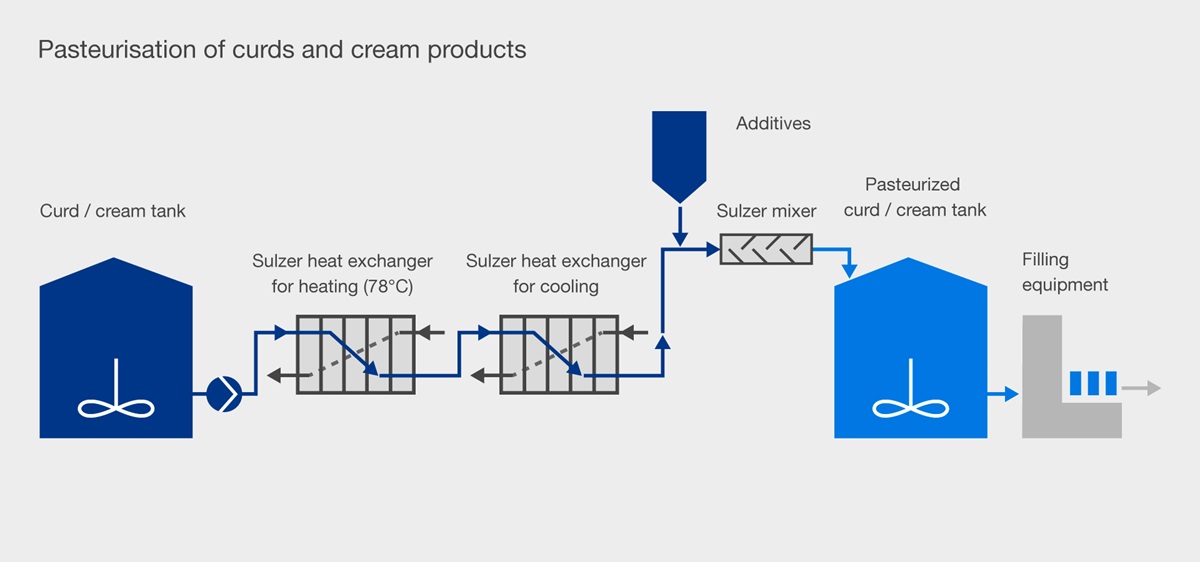

Curd and cream

The curd or cream pasteurization takes place at 78°C. Cooling down fast with a low pressure drop is a big advantage of Sulzer heat exchangers. Thanks to this, you can benefit of a homogenized curd or cream without separation of whey fluid. Keeping the whey fluid results in higher protein-content of the curd or cream.

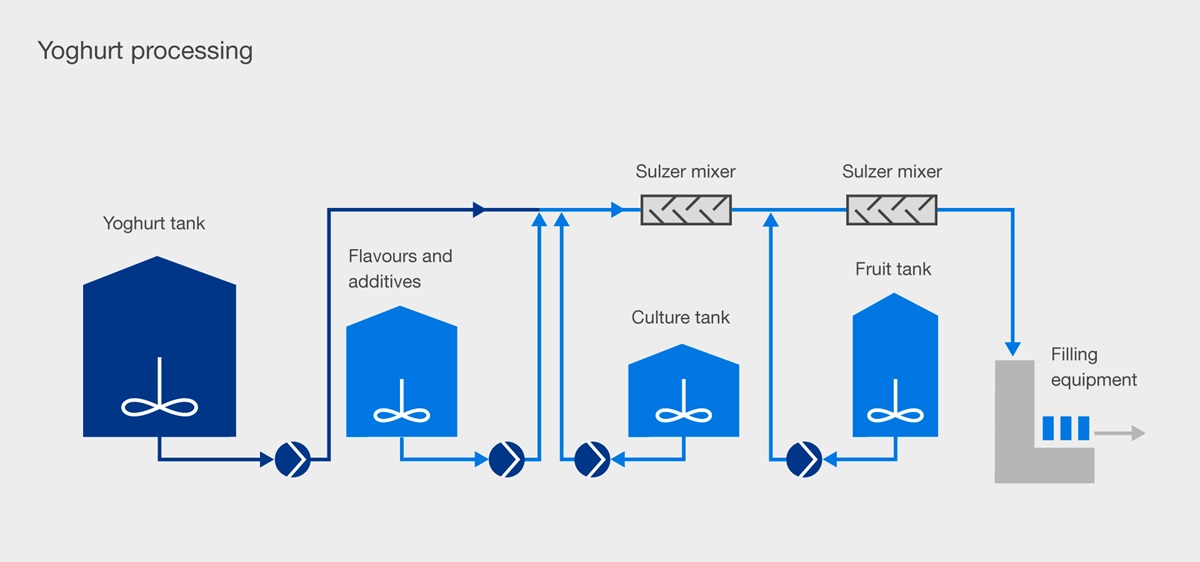

Yoghurt

You want to mix your yoghurt homogeneously without destroying the yoghurt structure and fruit pieces. The possibility of setting shear forces is a big advantage of Sulzer’s static mixers. Produce your yoghurt just as creamy as you want it.

Ice cream

You want your ice cream fluffy and tasty? Sulzer static mixers are market leader in mixing gas and liquids. Benefit from easy and homogenous dispersing of air into the ice cream base mass without cavitation holes. With the good mixing efficiency, you can save up to 20% of sterile air.

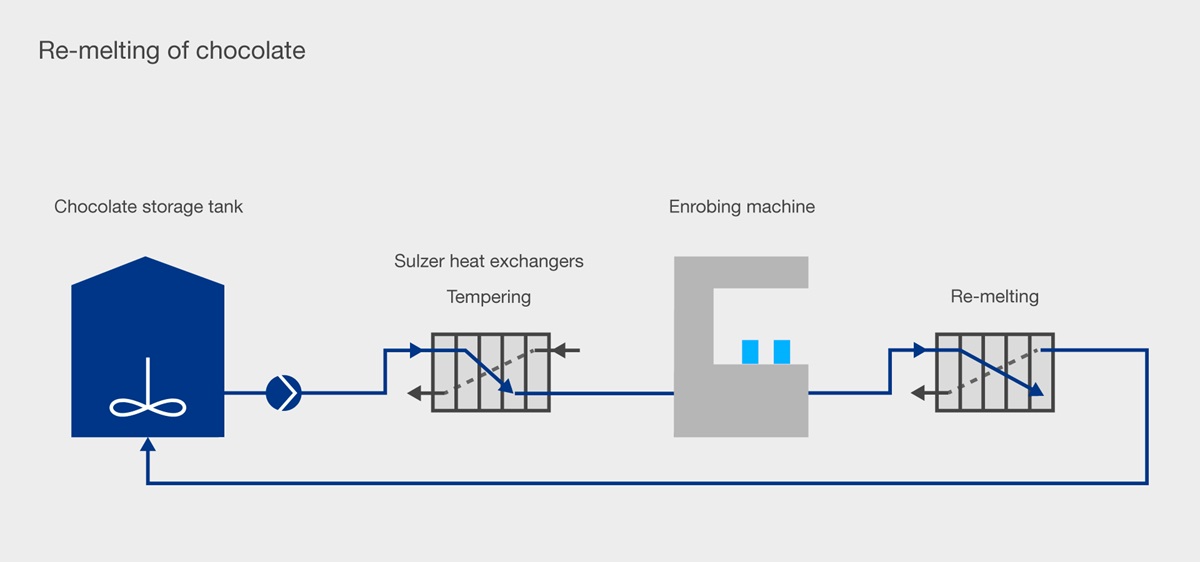

Chocolate

Melt it all to avoid crystals and lumps in the chocolate tank. The quick heat transfer of the Sulzer heat exchangers allows all fat crystals can be melted gently at the lowest possible temperature.

Products and services for this industry

Contact our Separation technology team directly