From early days to decades of innovation

During the 1900 Paris World Exhibition, Weise became fascinated with the Sulzer high pressure centrifugal pump. By 1903 he had started to develop his own high-pressure design and types using Sulzer as inspiration. Pump efficiencies quickly grew from around 50% to the 75-80% range and discharge pressures improved. Numerous new solutions were developed for applications, including tanker equipment.

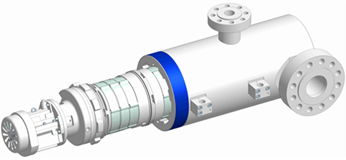

New technical global standards were introduced for double casing, radially split, multistage and between bearing pumps, defined in API 610 and embodied as BB5 pumps. This short, simple factual description (which in Sulzer terms is physically represented as the GSG range) does not express the magnitude in sizes, applications, technical variants, multinational customer sites and restless technical development phases this famous and reliable pump underwent during its decades of use.

In the early years, the GSG was just the refurbished and upgraded successor of the former HSG range, which was invented back in the 1950s. By November 1974, a technical team formed from research and development, marketing, sales and division management personnel had approved the concept of an all-new GSG.

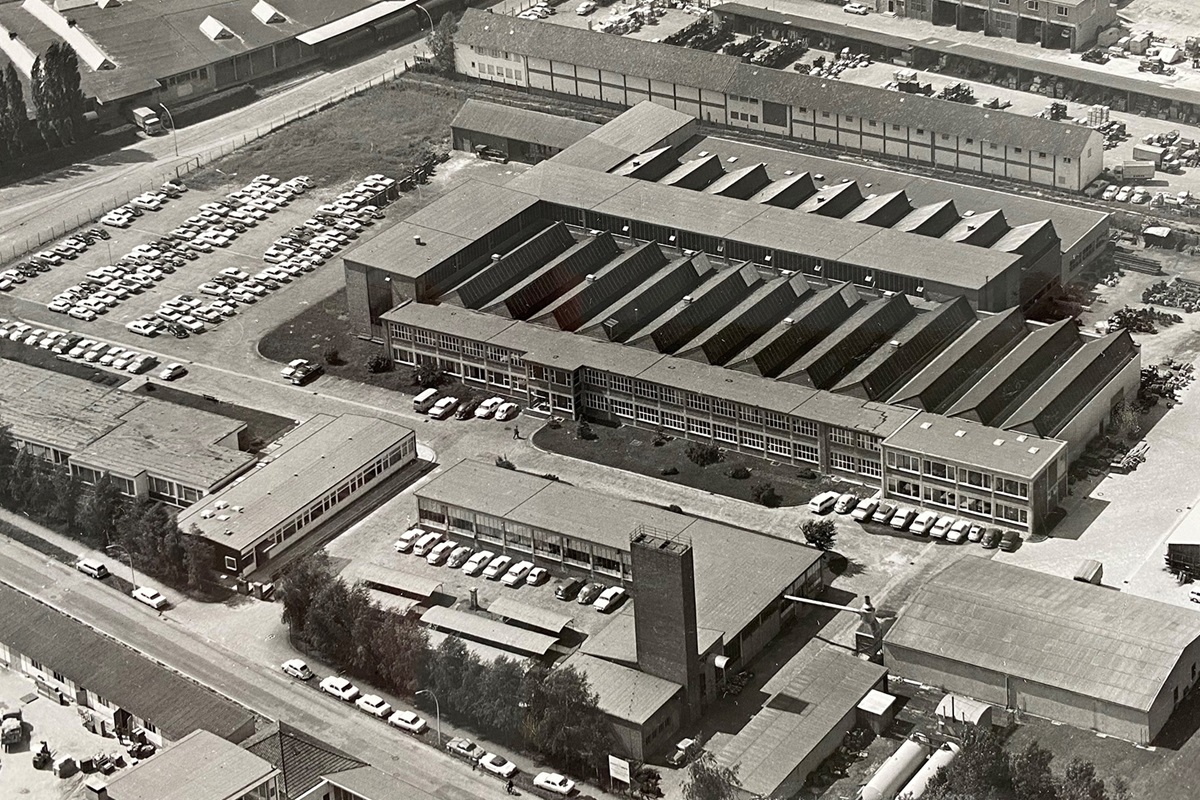

In 1972, Sulzer Weise GmbH, which today operates under Sulzer Pumps (Germany) GmbH, was fully acquired by the Sulzer Corporation based in Winterthur/Switzerland, building on a partial ownership stretching back to 1965.

Meanwhile, the GSG had incorporated multistage hydraulics, establishing a new state-of-the-art API 610 compliant product that made its way into chemical and refining applications for up to 125 bar in cast and 250 bar in forged versions. It also covered 50 Hz and 60 Hz applications for the global oil and gas sector.

Whilst in the early days the focus was on full API compliance, later operational reliability, easy maintenance and a higher-pressure range became the technical differentiators that provided a competitive market advantage. Customers were also looking for high resistance in chemical and abrasive applications. Special features like preheating systems and high-speed, lubricated bearing designs expanded the possibilities for pump usage.

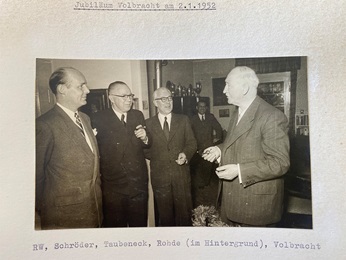

The seventies was also a decade of substantial organizational changes. The Weise family, after almost 100 years of family ownership and strong personal involvement, slowly withdrew from the operational side and handed over the business to the Sulzer corporation.

In the following years, substantial innovations took place, such as the back-to-back (B2B) pump design to maximize operating pressure and smoothen axial thrust. Bolted cover designs were introduced with additional smart twist locks for injection, reducing outer dimensions, weight and placing products in a prime competitive position.

During this period, the standard cast casing options were replaced by forged designs, all in different material codes and classes to serve the market’s needs for heavy duty high temperature and abrasive applications.

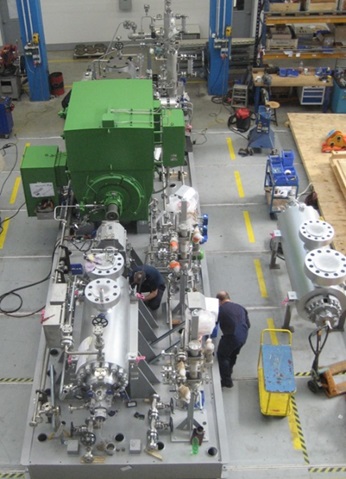

Today, where fossil fuels are being replaced by renewable alternatives and global CO2 emissions controlled by new technologies, the GSG has emerged for advanced applications like CO2 capture and storage. Great efforts have been made by Sulzer to produce the industry’s most environmentally sustainable liquid natural gas (LNG) pump systems.

This application requires strong sequestration and reuse of carbon. The new GSG CO2 export booster pump helps to reinject CO2 in depleted gas reservoirs to avoid emissions into the atmosphere. Whilst typical applications handle all types of known fluids, the differing flow dynamics of CO2 requires in-depth analysis of the stage-by-stage fluid conditions and calculations.

As long as mankind is transitioning to renewable energy, sustainable, high efficiency technologies for fossil fuel processes are obligatory. In this decade, the GSG has emerged to comply with these design specifications, with its hydraulics also delivering solutions for energy recovery.

As reducing wasted energy and process heat efficiency losses have reached higher priority for plant owners and operators, Sulzer Pumpen (Deutschland) GmbH is offering perfect solutions for hydraulic power recovery turbines (HPRT), managing the recollection of existing process energy drains in a highly sustainable manner.

A broad portfolio of scalable hydraulics offers support up to >2300kW tasks. Throttle valves and orifices reduce the pressure to required industrial process levels. By means of HPRT pumps, differential pressure of up to >80% can be fed back to the drive train, sustainably reducing energy consumption.

A long history of innovative high-pressure centrifugal pump developments, accompanied by the inventor mind set and culture of the Weise family, started in 1872.

Today, 150 years later, this strong foundation is still delivering new advancements for various fluid-based processes and systems. Sulzer Pumpen (Deutschland) GmbH, together with all our employees, is proud of this technical history and the importance of distributing leading technology and a magnificent Services portfolio to countries worldwide, where pumps like the GSG are operating today and will into the future.