Clean air

Helping you tackle climate change in a globalized world

Offering top-of-the-range carbon capture and storage (CCS) equipment that prevents the release of CO2 into the atmosphere, we can help you significantly tackle climate change whilst not compromising on performance.

Streamlined solutions for improved emissions capture

Our carbon capture and storage (CCS) project in the USA aimed to reduce the carbon dioxide (CO2) emissions of a fossil fuel power plant by 90%. To do this, we provided the mass transfer technology required for this capturing process.

Thanks to our customized solutions, we were able to help our longstanding US client to increase the efficiency of their equipment and lower their operation costs.

After China, the USA is the second highest emitter of greenhouse gases (GHG) in the world. Most GHG emissions in the USA stem from power generation. The WA Parish power plant — owned by Petra Nova Holdings and located in Texas — is the largest fossil fuel plant in the USA and one of the largest CO2 emitters in the country.

In 2013, Petra Nova Holdings announced a carbon capture retrofit on one of the four coal-fired units of its Parish plant. These CCS technologies help to mitigate GHG emissions and encourage the responsible use of fossil fuels.

Thanks to the retrofit, the Parish plant can now capture over 1 million tons of CO2 per year, significantly reducing the plant’s CO2 emissions as well as other pollutants, such as sulfur oxides (SOx) and nitrogen oxides (NOx).

How Sulzer can help your operations absorb CO2 more efficiently and cost effectively

Effective absorption columns helping you save on energy cost.

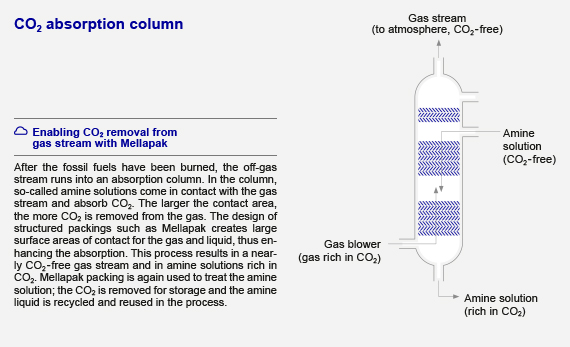

During power plant operation, CO2 emissions emerge during the process of burning fossil fuels. Before being released into the atmosphere, the CO2 is captured in an absorption column after which it can be safely stored underground or used for other purposes (e.g., enhanced oil recovery). See the diagram below to see this visually. Normally, these columns are very large and use a lot of energy. Thanks to the internal structures of our columns, we are able to reduce column size, helping you save on materials, space, and cost, including energy costs.

Cutting-edge technologies

Sulzer has significant experience in providing mass transfer technology for CCS. We have delivered column internals and engineering expertise for two of the largest CO2 capture demonstration projects worldwide. Thanks to our cutting-edge technology, customers are able to treat large amounts of flue gas more effectively, capturing CO2, NOx and SOx emissions. In addition to mass transfer technology, we also offer pumps for various stages of the CCS chain.

We are ready to work with your team and deliver solutions that not only help you maximize your company but also lead in the combat against climate change.