- Optimized mixing through precise agitation control and unmatched application know-how

- Reduced energy costs with high-efficiency propellers

- Robust design for long-lasting, reliable performance

- Expert assistance and rapid global support

- Easy maintenance and minimized downtime with a modular design

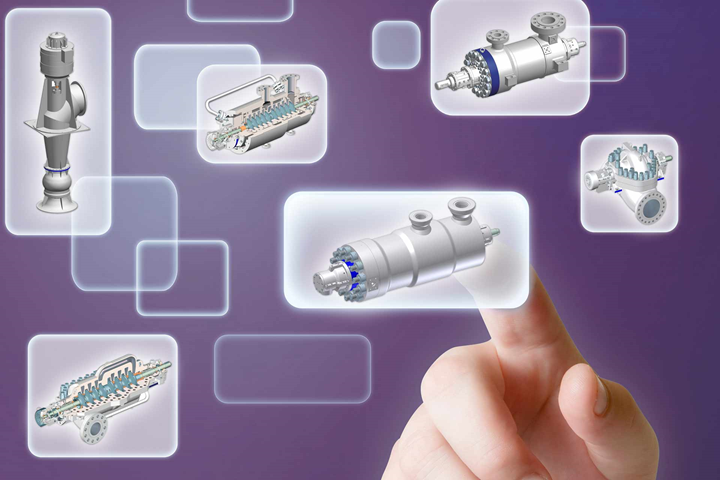

Scaba STA vertical agitator

Ready to optimize your mixing process?

The Scaba STA agitator delivers superior performance. Benefit from our expertise, energy efficiency and global service and support for your success.

- The Scaba STA is designed for flexibility, agitating a wide range of media in diverse tank setups.

- Water, wastewater, and other water-like media

- Viscous liquids

- Non-Newtonian liquids

- Organic sludge (e.g. from wastewater processes)

- Inorganic sludge (e.g. mineral slurries)

- Mineral suspensions

- Chemicals

- Paper pulp

Main design features

- High-efficiency propellers for low power consumption and improved mixing

- Versatile impeller selection for optimized mixing

- Smooth impeller design that minimizes shear in sensitive applications

- Long propeller lifetime with reduced wear from efficient hydraulics and smooth design

- Reliable, robust gearbox for long-term durability

- Rigid output shaft for stable, efficient power transmission

- Configured for high reliability with all individual components evaluated for the specific application

- Commercial gearbox for quick support and spare parts availability

- Optional bottom bearing for enhanced shaft stability

- Wide material selection ensures corrosion resistance and long-term performance

- Standard flange connection for easy installation and compatibility

- Optional lip seal protects against contamination and extends lifespan

Key characteristics

| Temperatures | Up to 120°C / Up to 248°F |

| Power | 0.25 to 55 kW / 0.35 to 75 hp |

| Impeller diameter | 400 to 3’000 mm / 16 to 118 in. |

| Shaft length up to 6 shaft steps | max. 30 m / max. 100 ft. |

| Shaft type | Solid or pipe shafts |

| Gearbox type | Parallel shaft drive with hollow shaft |

| Motor options | Gearmotor or gearbox with motor adapter (IEC or NEMA) |

Performance data as standard, with extended options available.