- Long and trusted experience in pulp, paper and board and other industrial segments

- Suitable for the most demanding, discharging high-consistency fibrous slurry tower applications

- Unique and reliable design

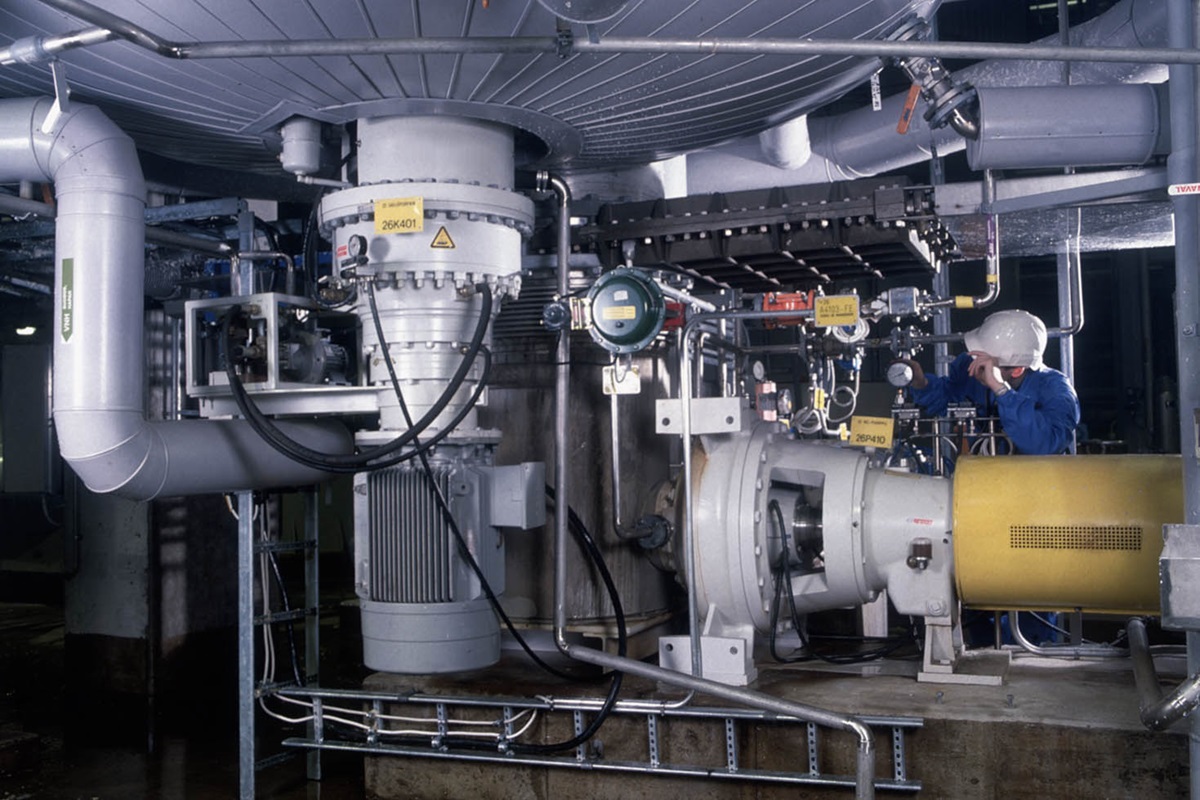

MC discharge scraper

Reliable discharging of MC and HC towers

Medium-consistency discharge scrapers are used for discharging high-consistency fibrous slurry towers to ensure process reliability, high efficiency, and low operating costs.

- Medium-consistency discharge scrapers with MC pump are used for discharging high-consistency towers

- Capability to 13% tower consistency without dilution, and to 20-35% tower consistency with dilution

- Outlet stock consistency is typically 8-13%

Main design features

- Reliable, high-efficiency hydraulics

- Wide variety of material options

- Innovative technical solution for reliable operation

- Reliable and heavy-duty design

Key characteristics

| Capacities | Up to 8000 ADMT/d |

| Pressures | Up to 10 bar / 145 psi |

| Temperatures | Up to 120 °C / 248 °F |