Turbomachinery solutions

At Sulzer, we specialize in the comprehensive maintenance and repair of Steam Turbines and Compressors, Industrial Gas Turbines, and Aeroderivatives.

Our dedicated team of experts works around the clock to ensure your equipment operates at peak performance. We pride ourselves on delivering customized solutions tailored to meet the unique needs of each client. Our flexibility in repair services allows us to address issues swiftly and efficiently, minimizing downtime and maximizing productivity.

What sets us apart is our commitment to building close relationships with our clients, ensuring we understand their specific challenges and requirements. Our 24/7 availability means we're always ready to respond to any emergency or maintenance need. We are also continuously investing in developing cutting-edge technology, enabling us to innovate new repair methods and enhance our service offerings.

At Sulzer, we are not just a service provider; we are your trusted partner in ensuring the reliability and longevity of your turbomachinery. Our approach is centered around providing holistic turbomachinery services; from inspection, repairs, new parts manufacturing and upgrades, our specialized technical team can find a repair solution that fits your needs.

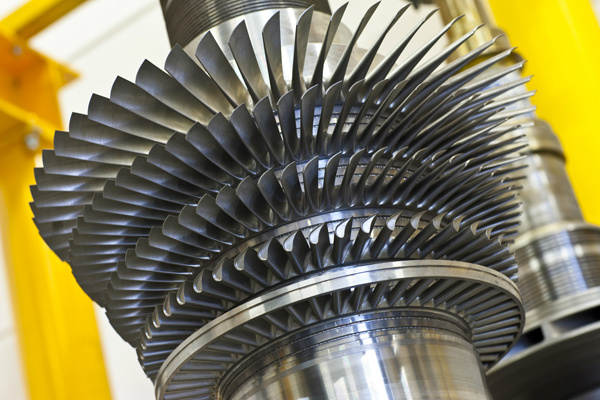

Industrial Gas Turbines

At Sulzer, we specialize in GE Frames ranging from Frame 3 to 9Es, Siemens and former Westinghouse W101-501FC/D, V series engines including V64, V84 and V94, as well as Alstom, Hitachi and Mitsubishi.

Our team has extensive experience in the repair and maintenance of industrial gas turbines, providing comprehensive services that ensure optimal performance of your equipment. Our expertise encompasses the complete lifecycle of gas turbines, from initial inspection and diagnosis to repair, balancing and reassembly. By leveraging advanced repair techniques and state-of-the-art technology, we deliver solutions that minimize downtime and extend the operational life of your turbines.

Our services include:

- Initial Inspection and Diagnosis

- Disassembly and Component Inspection

- Non-Destructive Testing (NDT)

- Welding and Coating

- In-House Manufacturing

- Reassembly and Testing

- Strategic Capital Parts Inventory

- Component Life Assessment

By partnering with Sulzer, clients benefit from reduced maintenance costs, improved equipment reliability, and enhanced overall efficiency. Our commitment to cutting-edge technology and strategic inventory management ensures that we can meet the needs of our clients swiftly and effectively.

Aeroderivative Gas Turbines

At Sulzer, we specialize in servicing legacy Rolls-Royce aeroderivative gas turbines, including the SGT-A20 (Avon), SGT-A35 (RB211), SGT-A05 (A501K), and Pratt & Whitney GG4/FT4, as well as marine gas turbines like the Tyne and Olympus.

Our global network of service centers and testing capabilities ensures top-tier support wherever you need it.

Overhaul Services: With over 20 years of experience, we provide high-quality overhauls, including disassembly, re-assembly, repair or replacement of critical components, and performance testing. Our centers of excellence and testing facilities worldwide ensure your turbines operate at peak performance.

Repair Services: We find the right repair solution for you using advanced techniques such as welding, coating, and blade rejuvenation, efficiently restoring most components and returning your engine to operation.

Field Service: Our dedicated field service division helps with installation and commissioning. Our specialized technicians, with years of experience, troubleshoot all types of aeroderivative gas turbines and power turbines, ensuring smooth operation.

Spare Parts: Recognizing that not all parts can be repaired and that downtime is costly, we maintain significant key inventory to quickly meet your needs. Our internal reverse engineering and parts manufacturing capabilities cover a wide range of components, from small consumables to blades and nozzles guide vanes.

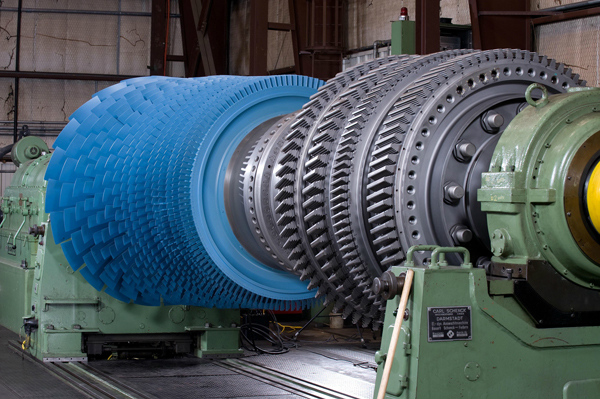

Steam Turbines and Compressors

At Sulzer, we are dedicated to providing tailored solutions for your steam turbine and compressor needs. Our high-tech repair techniques ensure that your equipment is back in operation quickly, minimizing downtime. Understanding the critical nature of rapid turnarounds, we continuously invest in advanced technology, enabling us to repair most damages effectively. Our commitment is to deliver high-quality solutions, focusing on getting your equipment running smoothly and efficiently.

We service all types of steam turbines and compressors, from axial flow, centrifugal to screw compressors, and from small to large steam turbines. Our comprehensive, one-stop-shop approach ensures that most services are performed in-house or within our network of qualified vendors, allowing for quick and reliable repairs.

Our offerings include:

- Disassembly/Reassembly, cleaning, non-destructive inspection

- Component repair

- Component and rotor balancing

- At-speed balancing

- Component Manufacture (rotors, blades, impellers, and trim parts)

- Field Service

Additionally, our experienced engineering team is able to perform root cause analysis (RCA), re-rates, material upgrades, and component redesigns to enhance the reliability and performance of your equipment.

Read more about our Turbo Services

Sulzer Services

Within Sulzer, we have two additional divisions dedicated to rotating equipment, aiming to provide a complete solution for all your rotating equipment needs. Our goal is to be your one-stop-shop provider, ensuring seamless service across all areas of operation.Our Pumps Services division specializes in the repair and maintenance of all types of pumps, delivering reliable and efficient solutions. Meanwhile, our Electromechanical Services division focuses on the comprehensive servicing of motors and generators, ensuring optimal performance and longevity. Together, these divisions complement our rotating equipment service portfolio, offering a full spectrum of expertise to keep your equipment running smoothly.

Contact our Turbo Services team

We're here to help! Get in touch to discuss your requirements with our turbomachinery experts.