- Long and trusted experience in all industrial segments

- Excellent performance

- Exceeds requirements of international ISO 5199 standard

- Unique and superior design features minimize life-cycle costs

- Quick and easy installation, safe operation, easy maintenance and service

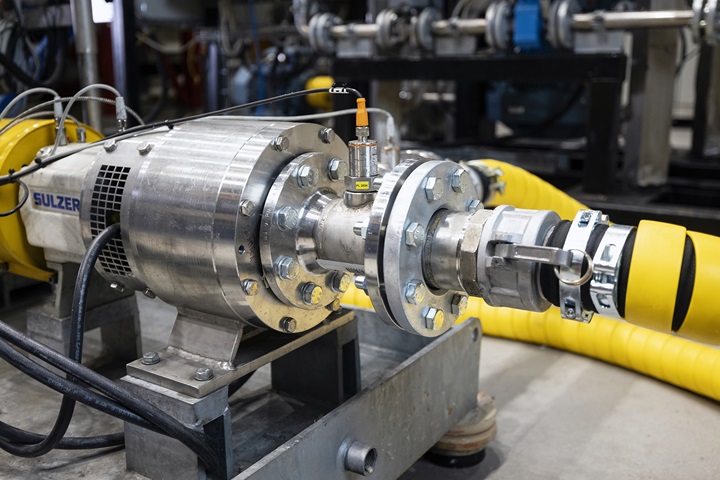

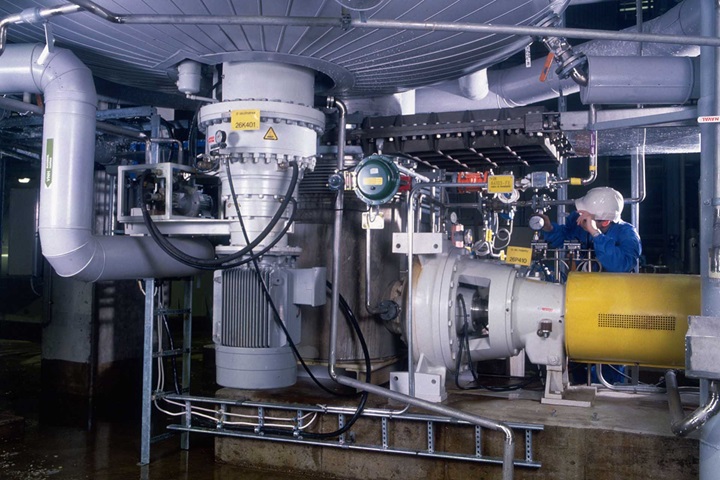

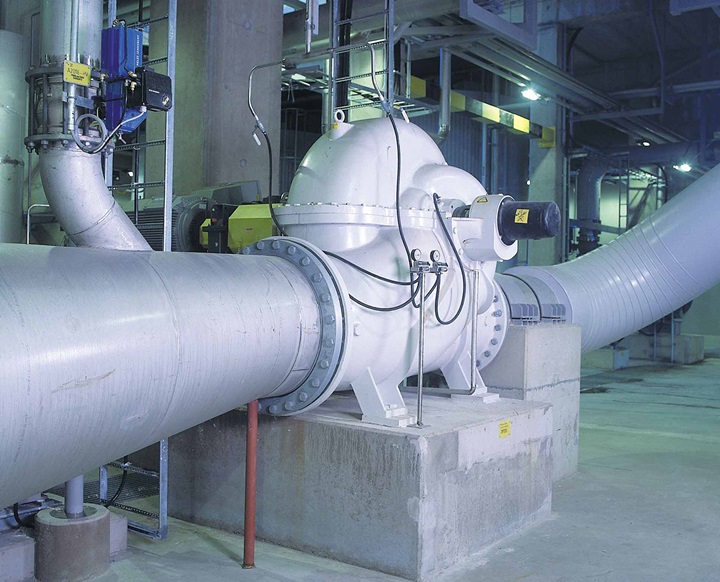

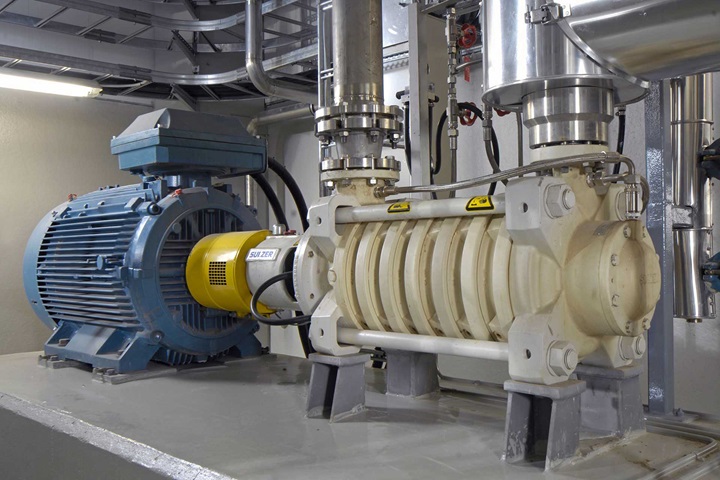

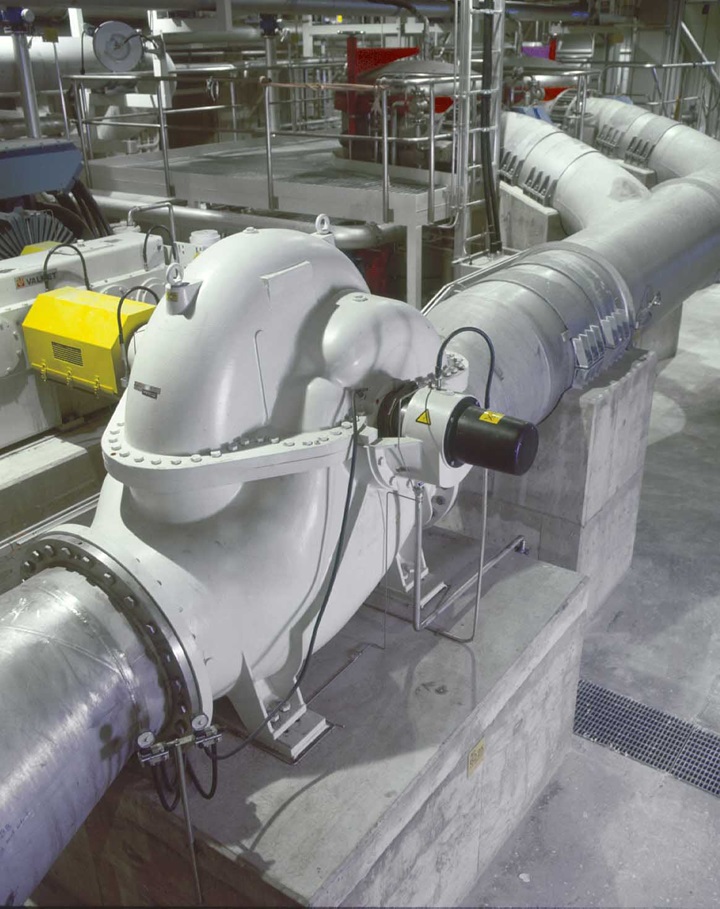

ZPP double suction, axially split single-stage centrifugal pump

High performance for demanding industrial applications

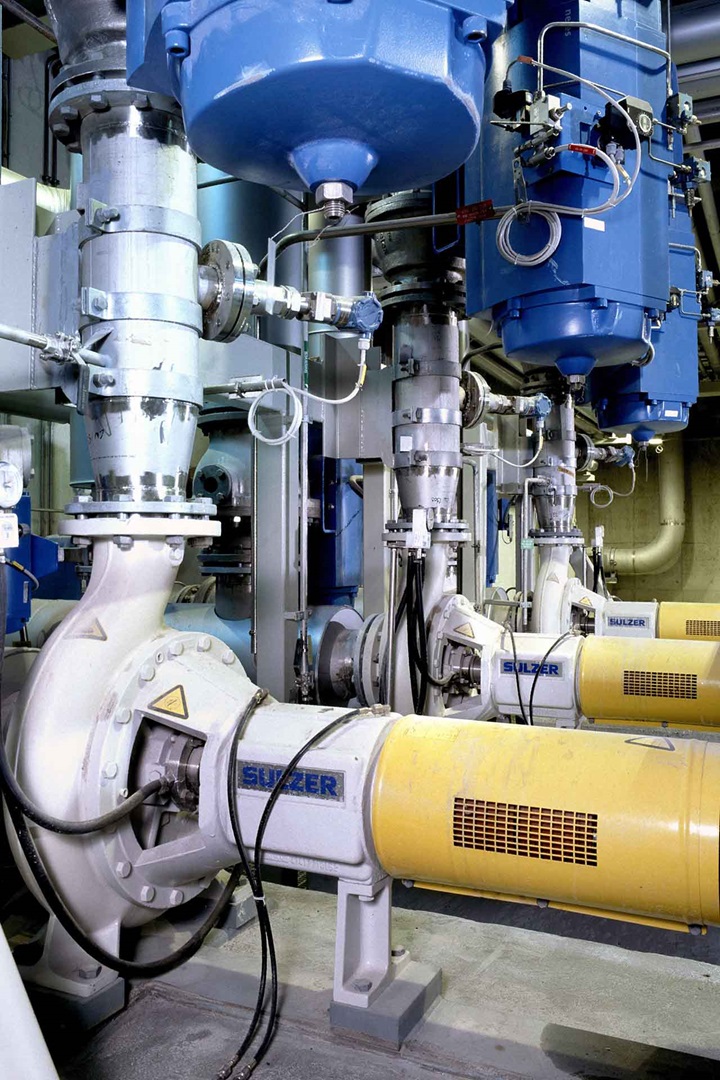

ZPP double-suction axially split single-stage centrifugal pumps are used for demanding high-capacity industrial applications to ensure process reliability, high efficiency, and low operating costs

- ZPP double-suction pumps are suitable for the most demanding industrial applications to pump clean and lightly contaminated, viscous and low-consistency fibrous liquids.

- ZPP pumps are especially designed for pulp and paper production as headbox and dilution feed pumps. They are used also in water and sewage works, heating and cooling systems, power plants and other critical applications.

Main design features

- Versatile, reliable, high-efficiency hydraulics and material options

- Innovative and reliable hydraulic design to minimize pressure pulsations

- Innovative shaft sealing solutions for reliable operation and reduced cost

- Reliable, simplified, and heavy-duty bearing units with a variety of different lubrication options

- Double suction impeller, with split, staggered and skewed vanes for high efficiency and low NPSH values

- Axially split casing design for easy inspection and maintenance without disturbing the piping or motor

- Special impeller and pump design enables pumping with low pulsations which is requirement in headbox feed applications

Key characteristics

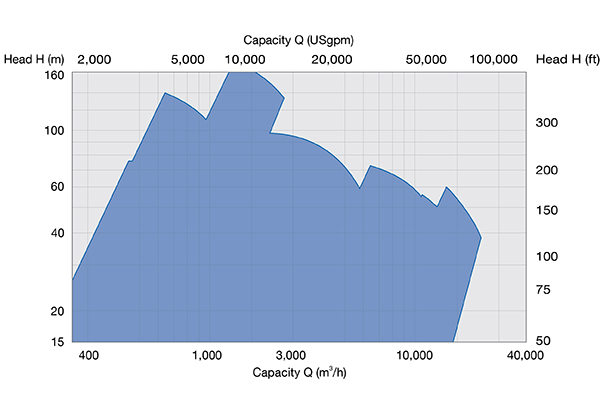

| Capacities | Capacity up to 25,000 m3/h / 110,000 USgpm |

| Heads | Head up to 160 m / 525 ft |

| Pressures | Pressure up to 20 bar / 290 psi |

| Temperatures | Temperature up to 120°C / 250°F |

| Discharge sizes | Discharge sizes from 250 mm / 10 in to 900 mm / 35 in |

| Maximum speed of rotation | Speed of rotation up to 3,600 rpm |

Documents

Brochures

-

Sulzer ejector for primingpdfLanguages:

Applications

-

Bio-based process developmentFind and develop efficient process equipment for bio-based products in an agile way with Sulzer as your trusted partner.

-

Chemical pulp fiber lineProven pumping, mixing and agitation solutions for your cooking, washing, screening, oxygen delignification, bleaching, and storage processes to ensure process reliability, high efficiency, and low operating costs.

-

Chemical recoverySulzer’s extensive product portfolio is designed to meet the most demanding hydraulic coverage requirements in your evaporation, recovery boiler, and white liquor preparation processes.

-

Chemicals for Pulp Paper and BoardTailored designs, features and material selections to meet the most demanding pumping, mixing, and agitation challenges in the production and preparation of chemicals, tall oil production, and lignin processing.

-

Coating and finishingA wide selection of highly efficient and reliable pumps and agitators for your pigment handling and color coating processes.

-

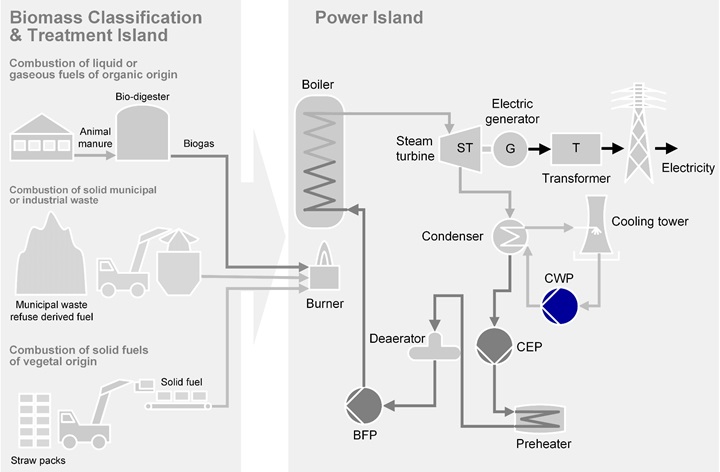

Cooling water pump (CWP) for biomass wasteCooling water pumps for biomass firing applications are typically horizontal axially split or end suction type. Vertical turbine type pumps are also available when required.

-

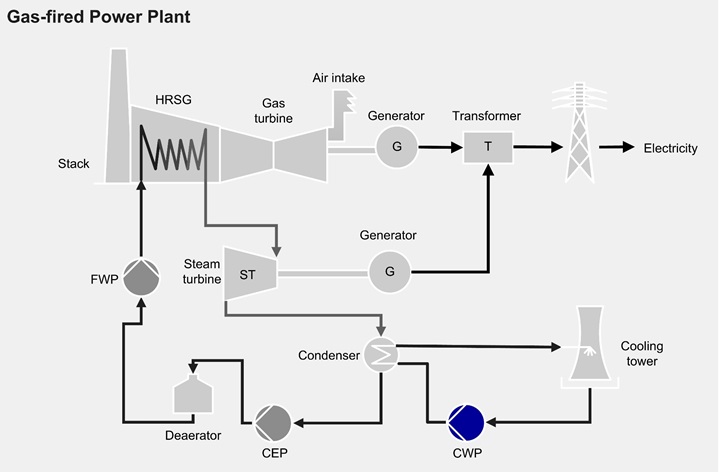

Cooling water pump (CWP) for gas-firedCooling water pumps (CWP) provide the fresh water to cool the exhaust steam in the condenser and pump it back to the wet cooling tower or the outlet of open cooling system. The major characteristic of the CWP is their high flow. In medium to large size gas-fired combined-cycle power plants, the CWP are vertical column type. In small power plants, the CWP could also be horizontal axially split type.

-

Cooling water pump (CWP) for geothermal plantsSulzer offers a variety of cooling water pumps, all made to provide your processes with the optimum temperatures for your processes. Installed in a water cooled condenser, the pumps will be active for your specific process.

-

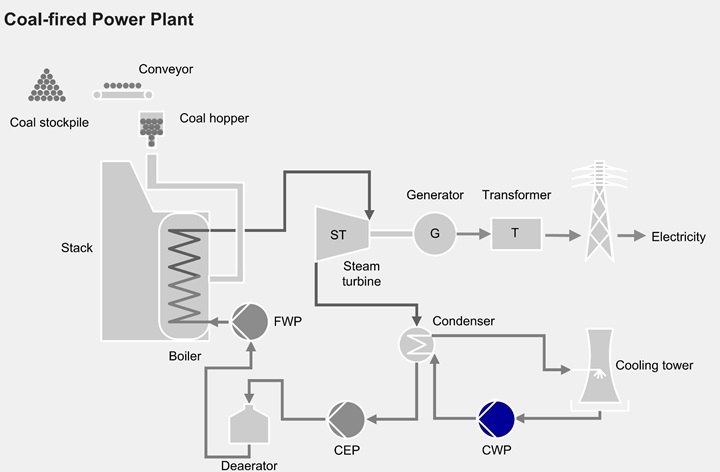

Cooling water pump for coal- and oil-firedCooling water pumps (CWP) provide fresh water to cool the exhaust steam in the condenser and pump it back to the wet cooling tower or the outlet of open cooling system. The major characteristic of the CWP is their high flow. In medium to large size coal- and oil-fired power plants, the CWP are vertical column type. In small coal and oil captive power plants, the CWP could also be horizontal axially split type.

-

Cooling water pump for heliostat central tower with direct steam generationCooling water pumps (CWP) provide fresh water to cool the exhaust steam in the condenser and pump it back to the wet cooling tower or the outlet of open cooling system. The major characteristic of the CWP is their high flow. CWP are vertical column type. In small plants, they can be horizontal axially split type.

-

Industrial water and effluent treatmentSulzer has a deep knowledge in wastewater treatment, and with our wide product portfolio we can now offer energy-efficient and reliable solutions for your water collection, neutralization, flocculation, sedimentation, cooling, aeration, sludge storage, digestion, and dewatering processes.

-

Mechanical pulp lineSulzer’s ideal product portfolio for challenging pumping, agitation, and mixing operations in refining, grinding, CTMP, screening, reject handling, and bleaching processes.

-

Paper and board machine and systemsSulzer’s extensive product portfolio is designed to meet the most demanding hydraulic coverage requirements and for all types of liquids, making it ideal for challenging pumping, agitation, and mixing operations in stock preparation, PM approach system, broke system, white water system, vacuum system, condensate system, and shower water system processes.

-

Power plantsSulzer’s extensive product portfolio to maximize the performance and reliability of your solid organic fuel biomass power plant, solid industrial or municipal waste fuel biomass power plant, and liquid or gaseous organic fuel biomass power plant processes.

-

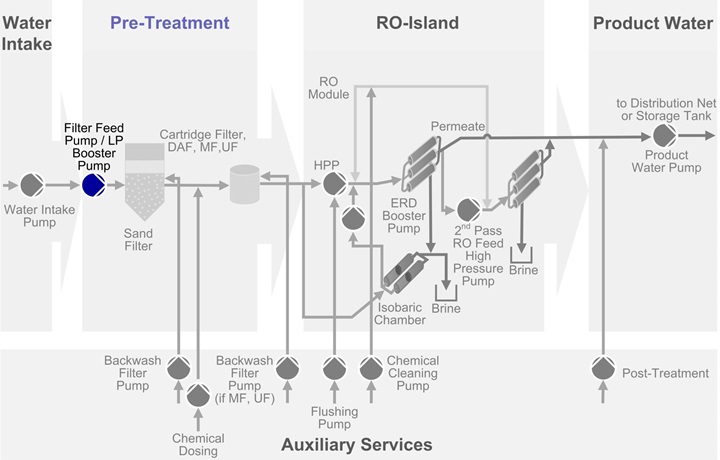

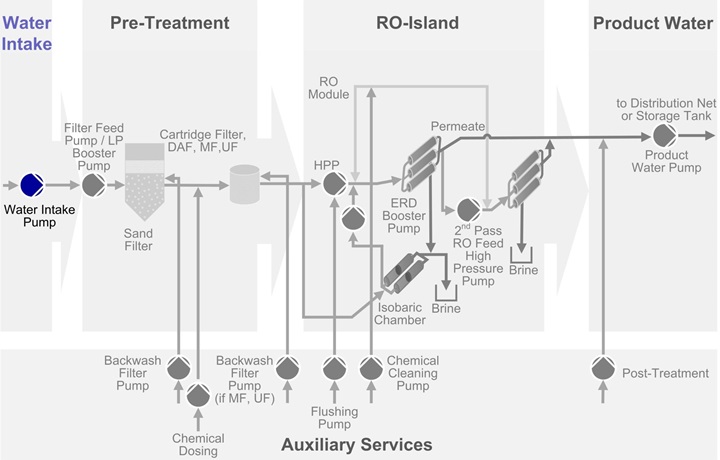

Pre-treatmentBefore reaching the RO Island, where specifically the desalination process will take place, raw water needs to be treated to ensure the required quality of the raw water to avoid fouling the RO membranes.

-

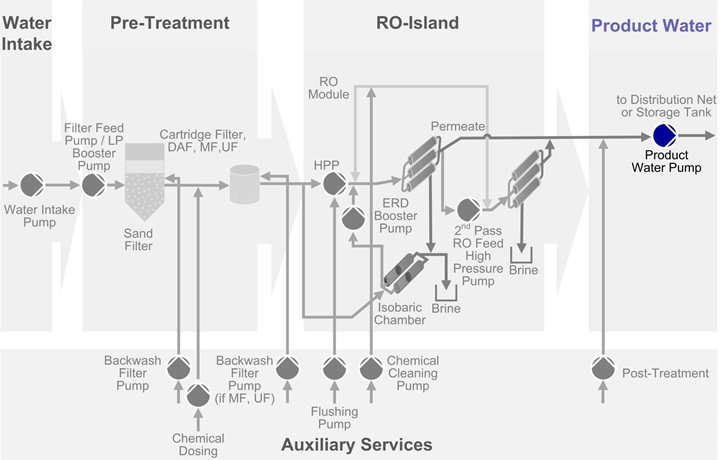

Product water transferAfter post treatment, product water is pumped to the storage tanks or into the water distribution networks.

-

Pulp drying machineIncreased hydraulic excellence for your approach, cleaning, drying machine, vacuum, broke, and white water system processes.

-

Recycled fiber lineEnergy-efficient products with low life cycle costs and a lighter environmental footprint for your pulping, screening & cleaning, flotation, washing, and bleaching processes.

-

Test equipment rentalRental equipment for textile and bio-based process development initiatives either at customer facilities or Sulzer’s development center.

-

Water intakeRaw water to be desalted, either sea water or brackish water will be taken from natural resource and pumped to pre-treatment stage. For sea water abstraction, different intake arrangements can be considered, which will define the pump type to be installed.

-

Water intakeWater supply is vital for our daily life. To abstract the water at the source, be it the sea, river, lake or dam, water intake pumps are needed. Sulzer offers a range of pumps that are specially engineered for such applications.

-

Water supplyMeeting today’s challenges and high requirements within water intake, sedimentation, sludge treatment, fine screening, and water distribution processes.

-

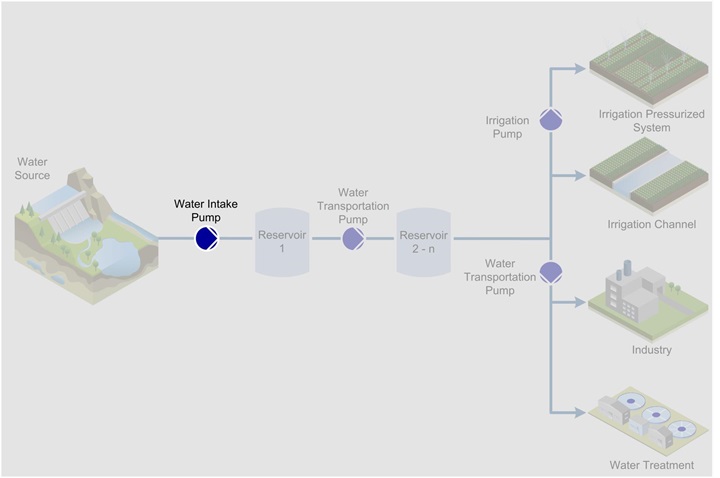

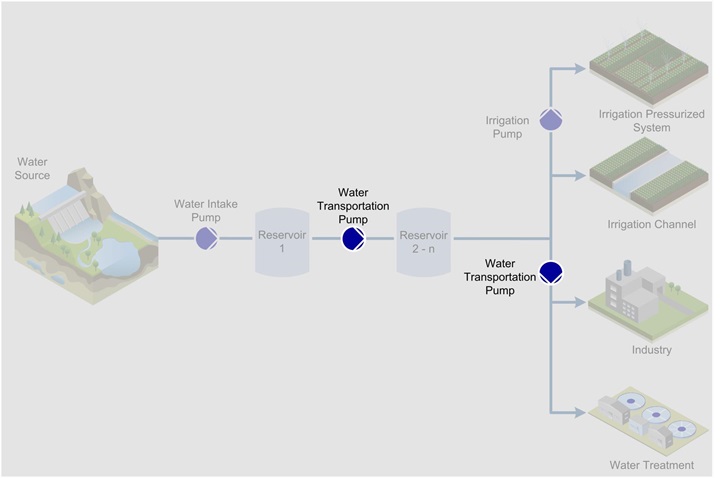

Water transportationWater transport pumps are pumping large volumes of water over mostly long distances and high geodetic heights to geographical areas or industries where it is required for different purposes. We offer various configurations according to your needs.

-

Wood yardEnergy-efficient products with low life cycle costs and a lighter environmental footprint for your debarking, washing, chipping, screening, and bark and waste streams handling processes.

Related links

Product and services

-

Z22 double suction axially split single stage centrifugal pumpZ22 double suction axially split single-stage centrifugal pumps are used for demanding high-capacity industrial applications to ensure process reliability, high efficiency and low operating costs.

-

Agitators, dynamic mixersSulzer SALOMIX™ and Scaba mixing and agitation technology offers a wide range of products for industrial applications. Side-mounted horizontal and top-mounted vertical agitators, dynamic chemical mixers, and tower and tank flow management products guarantee effective mixing and agitating processes.

-

Pump servicesReliable and efficient pump operation is critical for your business. Therefore you need a service partner that can respond fast and flexibly. Our pump services are second to none and provide solutions that help you to improve your processes and business performance.

-

Original pump spare partsOriginal spare parts machined to the correct tolerances and clearances give a perfect fit first time, every time. Our commitment to continuous improvement often allows us to supply parts with improved features, thus enhancing performance, extending equipment life, while reducing maintenance costs.

-

Service kitsWhen your equipment needs to be repaired you shouldn’t have to worry about spending valuable time searching for the right parts – or even worse, finding out that some small but vital parts are missing. With Sulzer service kits you get everything you need in one package.

-

Sulzer mechanical sealsSulzer mechanical seals are strong by design and have been proven very reliable in various pumping applications.

Industries

-

Chemical processingOur solutions for the chemical processing industry include pumping, separation and mixing, as well as services for rotating equipment and infrastructure. We offer experience in classical chemical, plastic, and pharmaceutical production as well as in processing renewable materials.

-

FertilizersOur pumps, mixers and agitators provide durability and reliability for fertilizers production as well as for corrosive and abrasive liquids and high gas content. Our specific industry experience also includes separation processes and servicing of pumps, compressors, turbines, and motors.

-

Mining and metalsLong experience and detailed knowledge of metals and mining applications with different raw materials makes Sulzer a reliable pump supplier for these industries.

-

BiofuelsBiofuels from renewable sources show great potential as sustainable transportation fuel. Based on our experience in demanding processes, we work with customers to develop advanced pumping, mixing, and distillation solutions for the production of biofuels, from pilot to commercial-scale installations.

Case studies

-

Trusted partner for new wood-based processesSulzer is a company with long and solid experience and proven expertise in several important customer segments. Pulp, board and paper processes and applications as well as new ones based on wood raw materials represent high-priority commitment and partnership areas for the business and product development organization. Read the whole article.

-

Case studiesWherever fluids are pumped, mixed, controlled or applied, we are there. See how our solutions create value for customers and learn how we can make your pumping and mixing processes more efficient and profitable, safeguarding your production and ensuring lasting reliability.

Videos

Careful commissioning of the pump plays a key role in the safe and reliable use of the pump

Connecting the pipes to the pump correctly is essential for ensuring the reliability of the pump

Talk or write to our experts to find your best solution.