-

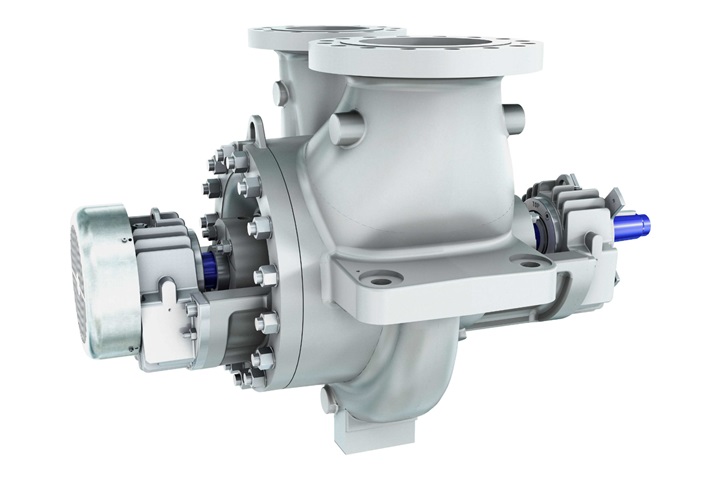

BBS and CD between bearings single stage pumpsThe BBS and CD models are API 610 (ISO 13709) type BB2, single stage, radially split pumps. They offer the widest range of hydraulic performance in the industry.

-

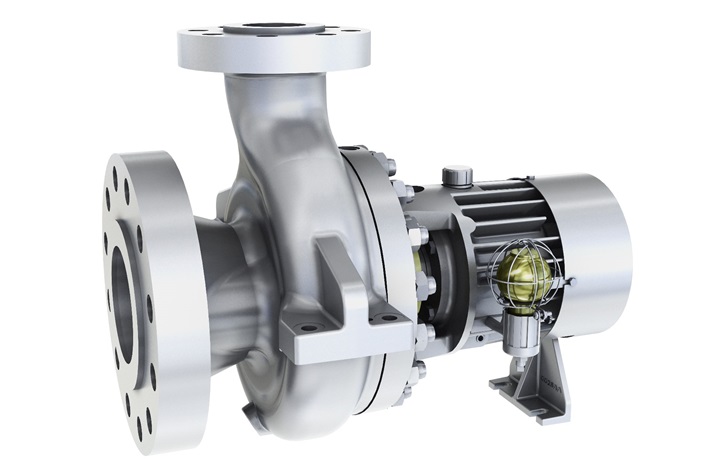

CPE ANSI process pumps range (ANSI/ASME B73.1)CPE ANSI pumps are specifically designed to exceed the strictest energy regulations for all industries as well as the requirements of ASME B73.1. With revolutionary hydraulics and high efficiency, they offer the lowest life cycle costs.

-

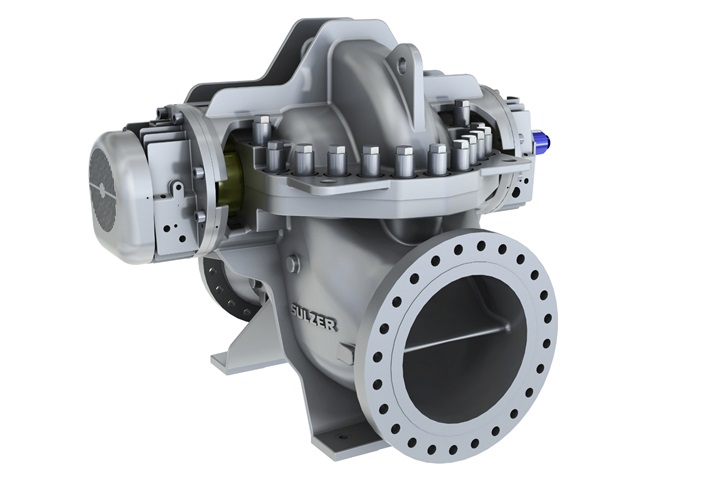

HSA axially split single stage between bearing pumpThe HSA API 610 (ISO 13709) Type BB1 is an axially split, single stage, horizontal, double suction, between bearing pump. The Sulzer HSA product range is ideal for long term continuous running services in refineries and pipelines. Its robust casing and custom hydraulics are specifically designed to ensure maximum availability and reduced total life cycle costs. The HSAv with its vertical shaft is used offshore where deck space is limited.

-

OHH overhung single stage pumpsThe OHH is our API 610 (ISO 13709) type OH2 overhung, horizontal, centerline mounted, single stage, radially split process pump.

-

OHHL low flow high head pumpsThe OHHL is our API 610 (ISO 13709) type OH2 low-flow horizontal overhung process pump. It covers the low-flow end of the OHH range map.

-

OHV overhung vertical inline pumpThe OHV is our API 610 (ISO 13709) type OH3 overhung, horizontal, centerline mounted, single stage, radially split process pump.

-

PRER and PRETR single-stage high-pressure pumpsPRER and PRETR are ISO 13709 (API 610) Type OH2 single-stage end suction process pumps, high pressure special design variants using PRE hydraulics but with special reinforcement to suit challenging high-pressure services.

-

SMH axially split single stage pumpSMH pumps are part of the broad single stage, double suction, horizontal split case family within Sulzer. Flowrates are provided to over 11,000 m3/h (50,000 GPM) and heads to over 200m (650 ft).

-

The new CPE ANSI process pump rangeSulzer’s groundbreaking CPE ANSI process pumps feature advanced design technology to meet modern industry demands. Being the most efficient solution on the market, they offer improved reliability and minimized total cost of ownership.

Offshore production - process and auxiliary systems

Synchronizing reliability with complexity

The complex processes performed on a typical FPSO rely on the performance of dozens of pumps handling a variety of liquids under widely varying process conditions.

Sulzer pumps are available in full compliance with the latest ISO13709 (API610) and ANSI standards as well as designed for general industrial applications.

Whatever the process or auxiliary application, Sulzer's pumps are optimized to deliver economic, reliable performance. In addition to be being designed for general industrial applications, our pumps are available in full compliance with the latest ISO 13709 (API610) and ANSI standards.

| OHH | OHV | SMH | BBS | CPT | |

|

Capacities |

Up to 2,250 m3/h / 10,000 USgpm |

Up to 1,450 m3/h / 6,800 US gpm |

Up to 11,000 m3/h / 50,000 USgpm |

Up to 5,000 m3/h / 22,000 USgpm |

Up to 1,600 m3/h /

7,000 US gpm |

| Heads |

Up to 360 m / 1,200 ft |

Up to 350 m / 1,120 ft |

Up to 200m / 650 ft |

Up to 450m / 1,500 ft |

Up to 220 m /

720 ft |

|

Pressures |

Up to 75 bar / 1,100 psi |

Up to 51 bar / 740 psi |

15 to 26 bar / 220 to 380 psi |

Up to 50 bar / 740 psi |

up to 2,5 MPa / 375 psi, |

| Temperatures |

-75°C to 425°C / -100°F to 800°F |

-160°C to 340°C / -256°F to 650°F |

Up to 150°C / 300°F |

Up to 425°C / 800°F |

Up to 260°C /

500°F |