Geothermal

Increase the lifetime of your geothermal equipment

We have broad experience in providing sustainable solutions that increase the reliability, lifetime, and efficiency of your geothermal machinery—and reduce your total maintenance costs.

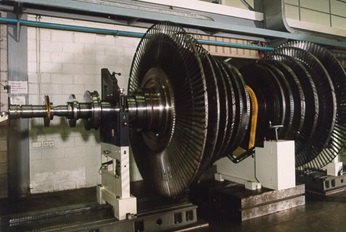

Machinery made from standard materials is used everywhere in geothermal plants. But standard materials often cannot withstand stringent plant requirements. Steam conditions and contaminations can vary tremendously depending on the location of the geothermal plant.

The lifetime and mean time between repairs are compromised due to the exposure of standard carbon steel components to pervasive steam conditions. Severe damage to the equipment is often found during inspections. Customers are not normally prepared for long, unforeseen outage periods due to extended repair times and procurement of new parts.

Solutions for shorter downtime

Sulzer has proprietary repair procedures to improve efficiency, reduce downtime, and extend equipment lifetime. Our procedures include the use of:

- Corrosion resistant materials

- Improved welding methods

- Specialized coatings

For the rotor bodies, blades, carriers, diaphragms, labyrinths, and seals of your machinery. We can also apply moist extraction systems on diaphragms and carriers to increase durability.

With our global network of locations and the ability to manufacture new parts promptly, we provide the help you need to get back online much faster. Our engineering teams apply their extensive knowledge to offer you advanced and timely solutions.