-

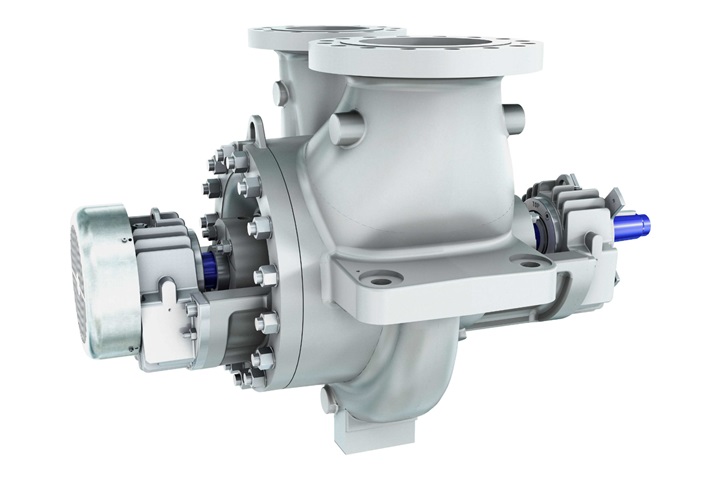

BBS and CD between bearings single stage pumpsThe BBS and CD models are API 610 (ISO 13709) type BB2, single stage, radially split pumps. They offer the widest range of hydraulic performance in the industry.

-

BBT and BBTD between bearings two stage pumpsThe BBT/BBT-D 2 stage, radially split ISO 13709 / API 610 Type BB2 pumps offers the widest range of hydraulic performance in the industry. The BBT-D double suction impeller provides reduced NPSH3 for tough services in refineries and other critical applications.

-

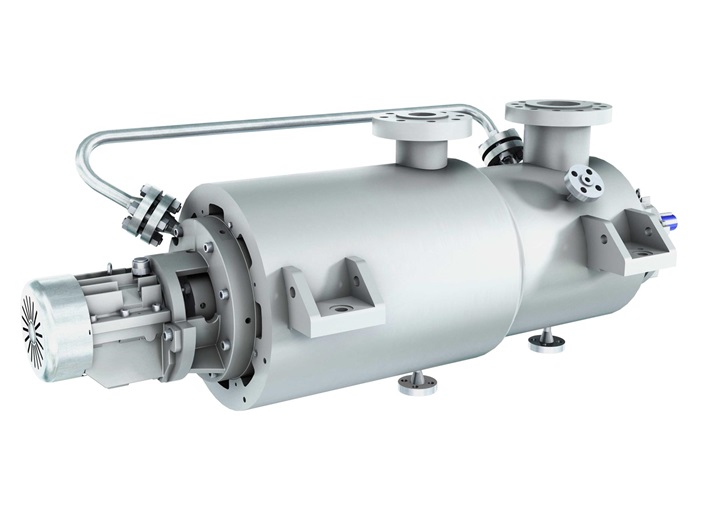

CP volute style barrel pumpCP ISO 13709 / API 610 Type BB5 radially split barrel casing pumps are used in both high-pressure oil production and high-temperature refinery applications.

-

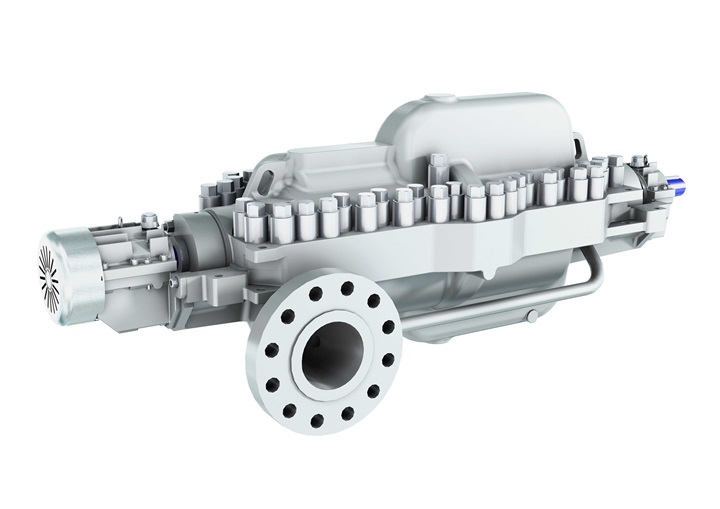

MSD axially split multistage pumpThe MSD pump has the broadest hydraulic coverage of any BB3 type multistage pump in the market. There are over 10 000 MSD pumps installed in product pipelines, boiler feed, water injection and even nuclear safety-related services around the globe.

Offshore production – seawater treatment

Adjusting salt levels to make the sea work for you

With enhanced oil recovery methods, often prior to injection sea water needs to be treated to remove or reduce salt content.

Sulzer’s pumps achieve this by delivering sea water to the SRU / SWRO membrane racks. The configuration of the sea water treatment module will determine which pump type is selected. While BB2 pumps are usually designated for this application, multistage BB3 and BB5 pumps are selected if the membrane requires a higher pressure.

| MSD | CP | BBS | BBT-D | |

|

Capacities |

Up to 3,200 m3/h / 14,000 USgpm |

Up to 1,000 m3/h / 4,400 USgpm |

Up to 5,000 m3/h / 22,000 USgpm |

Up to 2,300 m3/h / 10,000 US gpm |

| Heads |

Up to 2,900 m / 9,500 ft |

Up to 7,000 m / 23,000 ft |

Up to 450m / 1,500 ft |

Up to 760 m / 2,500 ft |

|

Pressures |

Up to 300 bar / 4,400 psi |

Up to 425 bar / 6,250 psi |

Up to 50 bar / 740 psi |

Up to 100 bar / 1,440 psi |

| Temperatures |

Up to 200°C / 400°F |

-50°C to 425°C / -46°F to 800°F |

Up to 425 °C / 800 °F |

Up to 425 °C / 800 °F |