-

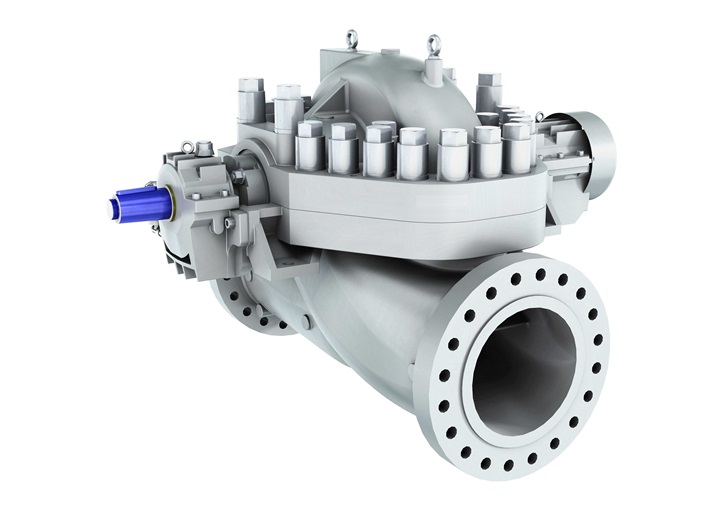

HSB axially split single stage between bearing pumpThe HSB API 610 (ISO 13709) Type BB1 is an axially split, single stage, horizontal, between bearing pump. Many HSB pumps are in service on crude oil pipelines in many parts of the world. Its robust casing and custom hydraulics are specifically designed to meet project requirements.

-

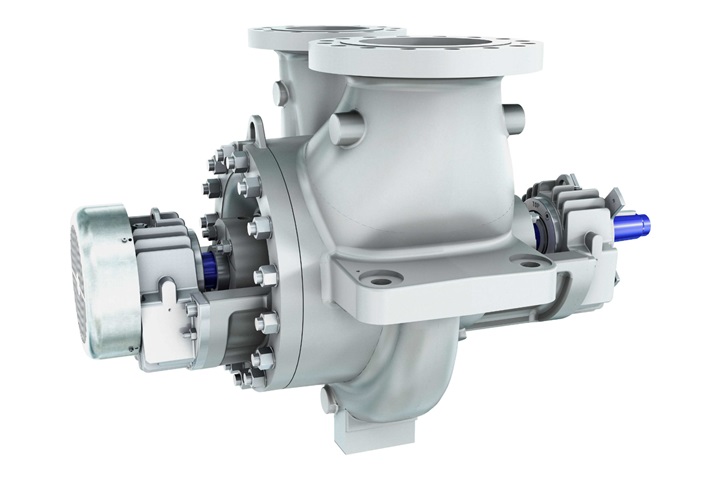

BBS and CD between bearings single stage pumpsThe BBS and CD models are API 610 (ISO 13709) type BB2, single stage, radially split pumps. They offer the widest range of hydraulic performance in the industry.

-

BBT and BBTD between bearings two stage pumpsThe BBT/BBT-D 2 stage, radially split ISO 13709 / API 610 Type BB2 pumps offers the widest range of hydraulic performance in the industry. The BBT-D double suction impeller provides reduced NPSH3 for tough services in refineries and other critical applications.

-

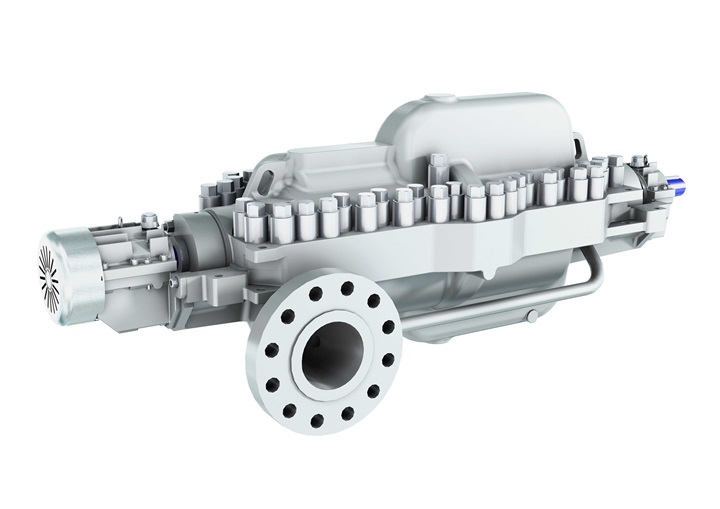

MSD axially split multistage pumpThe MSD pump has the broadest hydraulic coverage of any BB3 type multistage pump in the market. There are over 10 000 MSD pumps installed in product pipelines, boiler feed, water injection and even nuclear safety-related services around the globe.

-

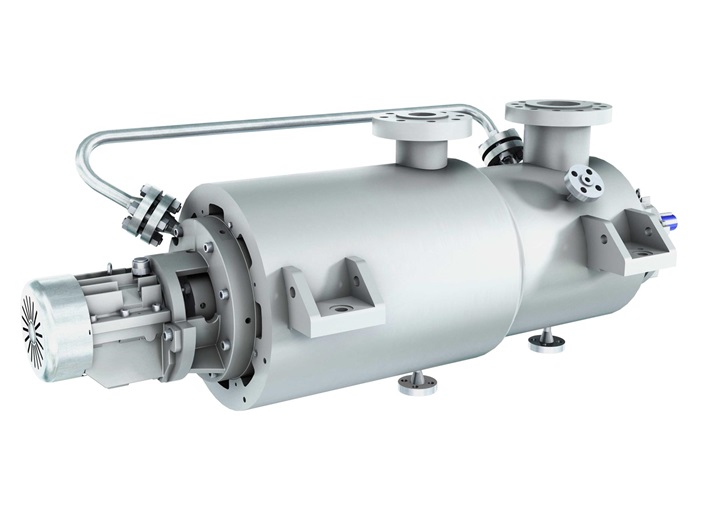

CP volute style barrel pumpCP ISO 13709 / API 610 Type BB5 radially split barrel casing pumps are used in both high-pressure oil production and high-temperature refinery applications.

-

GSG diffuser style barrel pumpThe GSG pump is the least costly form of ISO 13709 / API 610 Type BB5 high-pressure barrel pumps. The GSG back-to-back rotor stack is supplied on low- density services where rotor stability is critical.

-

SJD-API vertically suspended process pumpThe SJD-API are API 610 Type VS6/VS7 pumps whose design has evolved from many years of experience. They utilize Sulzer's low Net Positive Suction Head (NPSH) 1st stage, followed by unique high head per stage series hydraulics, to minimize the number of stages required.

-

HT-SJT vertical hydraulic power recovery turbineVertical Hydraulic Power Recovery Turbine (HPRT): Reduce costs and optimize energy recovery with Sulzer’s HT-SJT vertical HPRT solution.

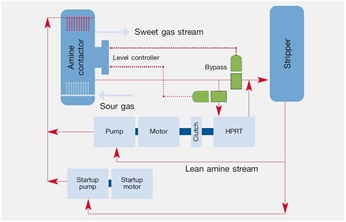

Hydraulic power recovery turbine

Minimize your energy consumption

There are two basic types of HPRT: Impulse (Pelton wheel) and reaction type.

Generally, pumps are a means of fluid transport that convert mechanical energy into hydraulic energy. Pumps increase fluid pressure and flow. When process conditions call for pressure to be dissipated, a pump running in reverse may be applied as a reaction turbine to capture that otherwise wasted energy (e.g. by throttling in a valve, dissipating the pressure energy into heat).

With many years of experience and expertise in this field, Sulzer is a leader in HPRT reaction technology with hundreds of installations.

The HPRT may be used to drive a pump, generator, compressor or other rotating machinery. Speed is governed by the inlet control valve, motor or generator and the electrical grid frequency. If required, a one-way clutch between a motor and the HPRT prevents the HPRT from robbing power from the train under low flow startup conditions. Due to high gas volume fraction carryover, experience strongly indicates that conservative speeds are prudent on Pump-Motor-HPRT trains in fertilizer plants.

Typical Hydraulic Turbine Installations

Split range liquid level controllers are typically used to regulate turbines. The controller adjusts the HPRT inlet valve or further open the bypass valve when the turbine is overpowered.

Overspeed trip devices are often furnished with hydraulic turbines. This device shuts the HPRT inlet valve and activates overspeed alarms when required.