- Reliable and long-lasting

- Low pressure drops and therefore higher efficiency

- Possibility of future increase in aeration capacity

- Quick and easy installation

- Flexible layout design

- High temperature endurance

- Suitable for aggressive wastewater

Disc diffuser system type ABS

A reliable solution for efficient oxygen transfer

The reliable disk diffuser system is one of the world’s most widely-installed fine-bubble aeration systems, available in four alternative diffuser models. Preassembled diffuser elements enable fast and easy installation. Retrofits are available to increase aeration efficiency.

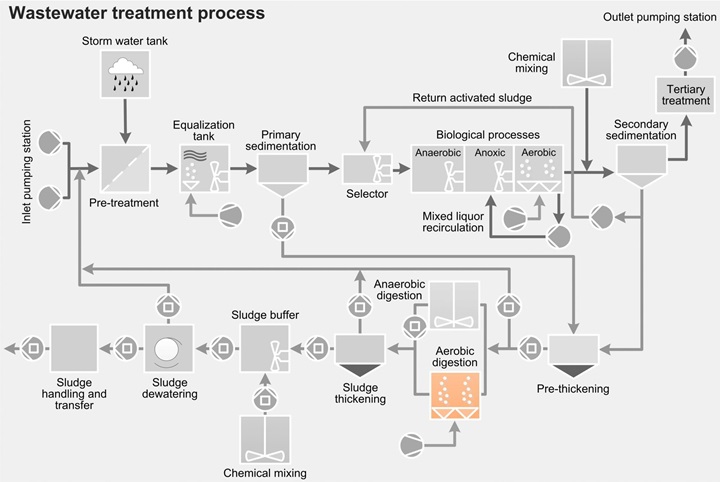

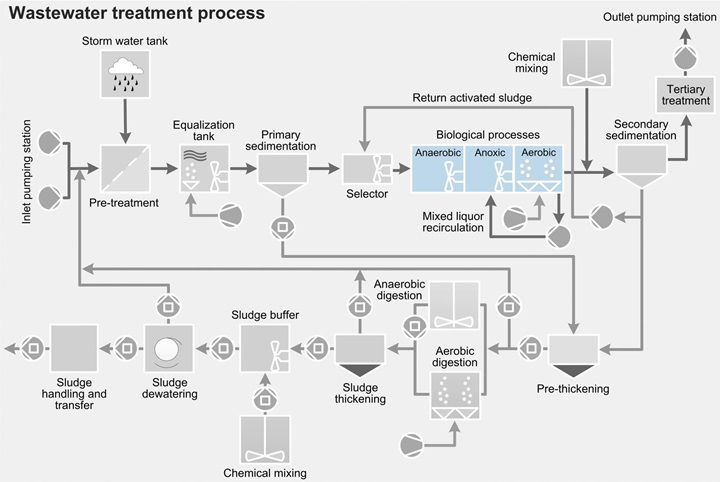

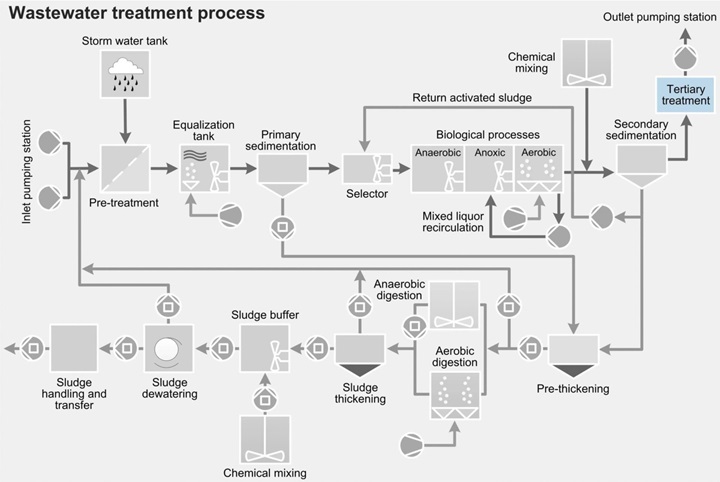

- Aeration of municipal wastewater

- Aeration of industrial wastewater, with some restrictions

Main design features

All diffusers have a built-in non-return valve which provides additional safety to the treatment process by preventing sludge infiltration into the aeration piping system when the air flow is interrupted. The KKI215, and PRK/PIK300 diffusers are interchangeable for retrofits, offering high flexibility.

Diffusers with EPDM rubber membrane discs:

PIK300 fine-bubble

- Polypropylene main body and an antifriction ring to protect the membrane

- Suitable for both continuous and non-continuous aeration processes

PRK300 fine-bubble

- Strong main body, making it suitable for SBR, MBR, and MBBR processes

- Antifriction ring protects the membrane

- PRF300 retrofit for upgrading 215 mm diffusers to more efficient systems

KKI215 fine-bubble

- Suitable for both continuous and non-continuous aeration processes

- Special support for use in deep basin applications, in water up to 15 m deep

Sucoflow DS 20 fine-bubble

- Ideal for high-density and retrievable aeration systems

- Easy-to-fit thread connection

Key characteristics

Diffuser diameter |

PIK300, PRK300: 336 mm KKI215: 215 mm Sucoflow DS 20: 500 mm |

|

Membrane surface area |

KKI: 0.025 m² PIK, PRK: 0.060 m² Sucoflow DS 20: 0.183 m² |

Operating range (+20°C; 1 013 mbar) |

KKI215: 0.5–4 m³/h PIK300, PRK300: 1.5–8 m³/h Sucoflow DS 20: 1–15 m³/h |

Max. operating temperature: |

PRK300, KKI215: 80°C PIK300, DS 20: 100°C |