- Solid organic fuel biomass power plant

- Solid industrial or municipal waste fuel biomass power plant

- Liquid or gaseous organic fuel biomass power plant

Power plants

Reliable technology for power plants

Sulzer’s extensive product portfolio to maximize the performance and reliability of your solid organic fuel biomass power plant, solid industrial or municipal waste fuel biomass power plant, and liquid or gaseous organic fuel biomass power plant processes.

- Boiler feed pumps – MBN, MC, MD, ME Ranges

- Main condensate pumps – MBN Ranges, Vertical SJD-CEP pumps

- Other condensate pumps – AHLSTAR™ A Range, P-pumps

- Main cooling water pumps – SMN pumps, Vertical SJT/SJM CWP pumps, P-pumps

- Other cooling water pumps – AHLSTAR™ A Range

- Hot water circulation pumps – ZE and ZF ranges

- Flue gas desulphurization pumps – AHLSTAR™ A, W Ranges, material 654 SMO

- District heating pumps – ZPP, Z22, AHLSTAR™ A Range

- Auxiliary pumps – AHLSTAR™ A Range

Products

-

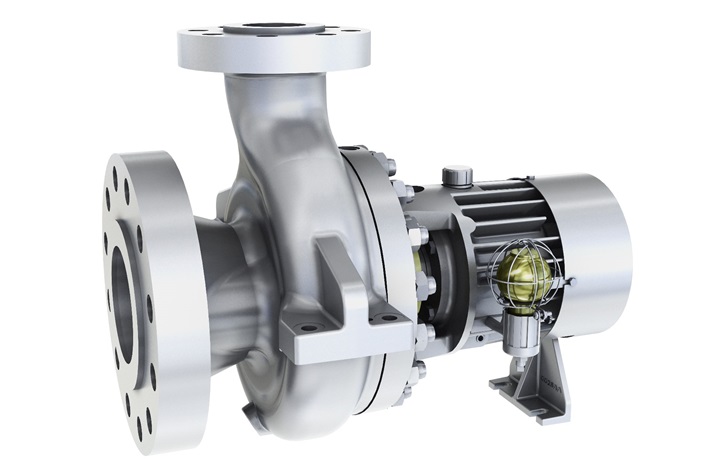

AHLSTAR A process pump rangeAHLSTAR A end-suction single-stage centrifugal process pumps are used for demanding industrial applications to ensure process reliability, high efficiency and low operating costs. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR APT process pump rangeAHLSTAR APT end-suction single-stage centrifugal process pumps are used for demanding industrial applications to ensure process reliability, high efficiency and low operating costs. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR WPP/T wear-resistant process pump rangeAHLSTAR WPP/T wear-resistant end-suction single-stage centrifugal pumps are designed for abrasive and erosive pumping applications, such as lime milk and mud, and coating pigments. The pump exceeds the requirements of ISO 5199.

-

JVCR high pressure canned LNG loading pumpThe JVCR pump is an ISO13709 / API610 Type VS6 vertical multistage can pump that is used in situations where Net Positive Suction Head Available (NPSHa) is limited. A wide range of hydraulics, discharge headgear, and pressure ratings may be supplied depending on individual application requirements.

-

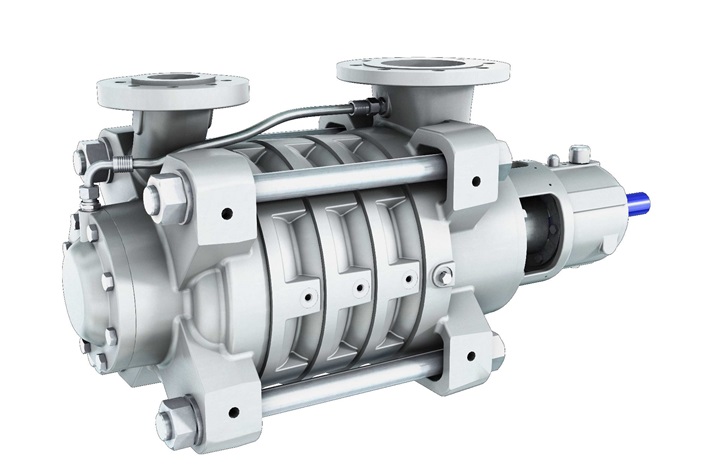

MBN multistage ring section pumpThe MBN pumps are ideal for use in high-pressure applications. They have a big variety of nozzle position options, thus providing flexibility during installation and simplifying the piping design.

-

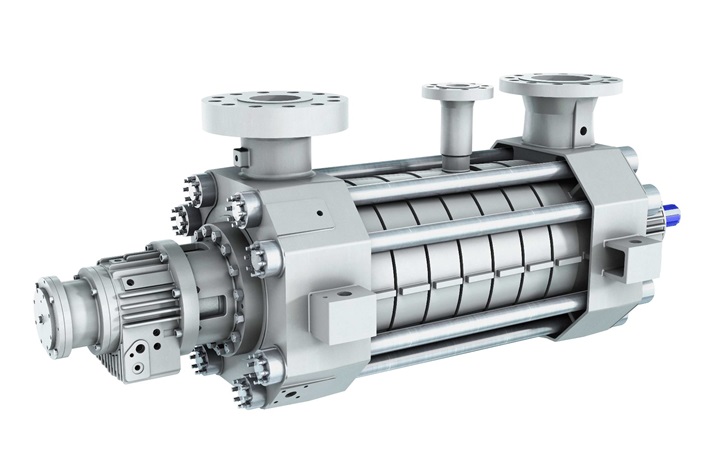

MC high pressure stage casing pumpM-series pumps have a modular design thus allowing Sulzer to find the most efficient solution to meet customer requirements.

-

MD high-pressure stage casing pumpBoth investment costs and lifecycle costs are taken into consideration when designing the optimum possible pump as an optimized hydraulic design guarantees maximum efficiency.

-

PRER and PRETR single-stage high-pressure pumpsPRER and PRETR are ISO 13709 (API 610) Type OH2 single-stage end suction process pumps, high pressure special design variants using PRE hydraulics but with special reinforcement to suit challenging high-pressure services.

-

SALOMIX™ SSA side-mounted agitatorsA robust, belt-driven agitator for light to heavy duties. Agitator performance can be adjusted through other drive combinations. Features the new high-efficiency EX3 propeller.

-

SJD-CEP vertical multistage can condensate extraction pumpSJD-CEP vertical can condensate extraction pumps, are specified wherever limited NPSH is available, either due to system constraints or liquids operating near to their vapor pressure, typically for condensate extraction and heater drain pump applications.

-

SJT-CWP vertical cooling water pumpThe SJT-CWP are "engineered to order" large flow vertical pumps for industrial pumping needs and sump design, with semi-open or closed cast impellers available in sizes starting from 350 mm (14") impeller diameter and nq 75 (Ns 3'870).

-

ZE/ZF end suction pump rangeThe ZE/ZF are ideal pumps for arduous industrial applications handling clean, cold or hot liquids, including hydrocarbons and light chemicals.

-

ZPP double suction, axially split single-stage centrifugal pumpZPP double-suction axially split single-stage centrifugal pumps are used for demanding high-capacity industrial applications to ensure process reliability, high efficiency, and low operating costs

Related links

-

Pump servicesReliable and efficient pump operation is critical for your business. Therefore you need a service partner that can respond fast and flexibly. Our pump services are second to none and provide solutions that help you to improve your processes and business performance.

-

Original pump spare partsOriginal spare parts machined to the correct tolerances and clearances give a perfect fit first time, every time. Our commitment to continuous improvement often allows us to supply parts with improved features, thus enhancing performance, extending equipment life, while reducing maintenance costs.

-

Service kitsWhen your equipment needs to be repaired you shouldn’t have to worry about spending valuable time searching for the right parts – or even worse, finding out that some small but vital parts are missing. With Sulzer service kits you get everything you need in one package.

-

Sulzer mechanical sealsSulzer mechanical seals are strong by design and have been proven very reliable in various pumping applications.

-

Service centers for rotating equipmentFind the service center nearest to you. With more than 100 service centers worldwide, we are always close to the customer.