- Centerline mounting to allow free thermal expansion and high nozzle loads

- Minimum bearing span to minimize shaft deflection

- Single cover casing design to reduce overhaul times

- Chrome steel casing with good corrosion resistance and excellent mechanical properties is standard; other materials available

- Single mechanical seal provides higher efficiency

HZB double suction volute pump

Double suction liquid solutions for tough conditions

The HZB is a horizontal, radially split, single stage, double suction, centerline mounted pump. The HZB pumps are ideal for use in arduous industrial applications for handling clean, cold or hot liquids as well as for safety-related services in nuclear power stations.

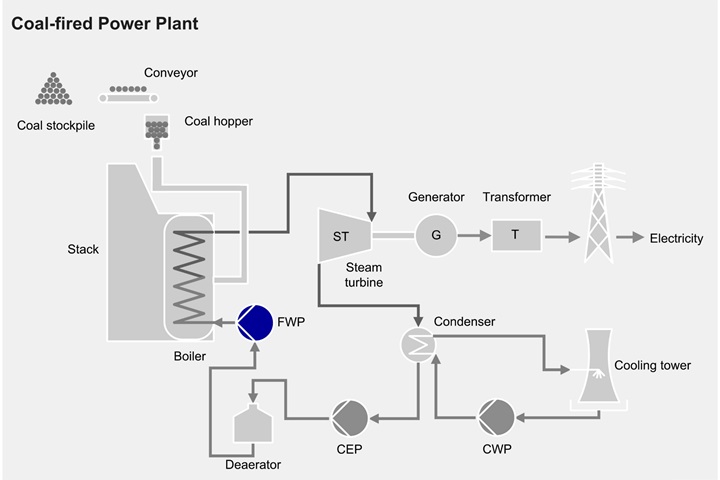

- Booster pumps for large boiler feed water units in thermal and nuclear power stations

- Safety-related pumps in nuclear power stations

Main design features

- Double suction impeller with staggered vanes for low Net Positive Suction Head required (NPSHR) and low-pressure pulsations

- Different nozzle positions are possible

- Amply sized sleeve radial and tilting pad bearings with forced lubrication as standard

- Optional self-contained oil lubricated bearings

- Stiff shaft ensures that critical speed is a minimum of 20 % above the maximum operating speed

- Mechanical seal jacket cooling

Key characteristics

| Capacities | Up to 5,500 m3/h / 29,000 US gpm |

| Heads | Up to 340 m / 1,115 ft |

| Pressures | Up to 48 bar / 700 psi |

| Temperatures | Up to 220°C / 428°F |

| Discharge sizes | Up to 400 mm / 16 inches |

Performance range

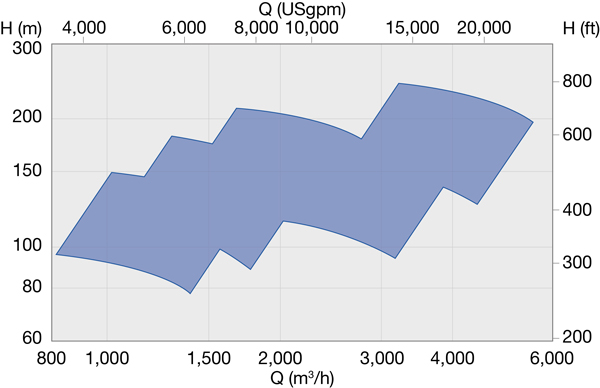

Performance range 50 Hz

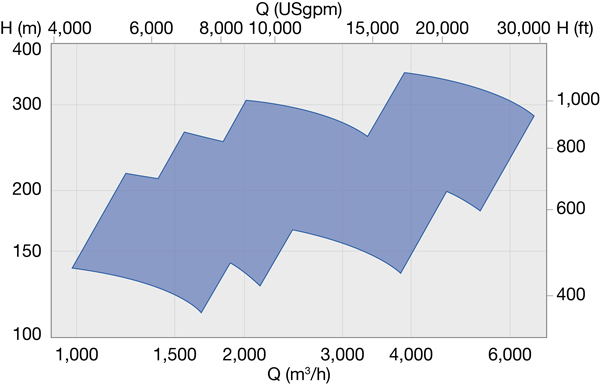

Performance range 60 Hz