- Confirmed values for processes

- Process validation eases decision making

Process validation

Offering state-of-the-art validation services

- For efficiency control of a column set up

- For separation processes with a hybrid process

- For separation processes with unknown components or chemicals

Reasons for process validation

There are various reasons for using laboratory and pilot tests to evaluate a separation process. Typically, we provide process validation:

- To support the design of a separation process with experimental data

- To confirm simulation results for a separation process with experimental data

- To support the design of a separation process with unknown components

- To confirm the separation efficiency of a proposed column set-up

- To support the design of a separation process for components for which no or only limited data is available

- To evaluate the interaction of different separation units in a hybrid process

- To evaluate the influence of chemical reactions in a separation process

Results of a process validation

The test results are summarized in a report. This report then forms the basis for the subsequent engineering work and for the proposed process solution for your separation task.Procedure

The first step in setting up a laboratory or pilot test is a preliminary simulation or estimation of the separation tasks. Depending on the required effort, we can provide this service as part of a study, or an engineering services project, or just together with the test. Following these tests, these simulations, or calculations, will be further improved based on the results of the trials, and will be used to support the design of the proposed unit for the separation task.

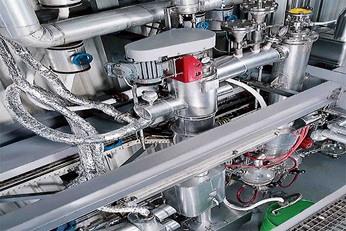

Wide range of unit operations

We can provide you with laboratory and pilot test work for all unit operations in our portfolio, for example:

- Distillation

- Absorption

- Liquid-liquid extraction

- Membrane processes including vapor permeation and pervaporation

- Film evaporation technologies

- Layer and suspension crystallization

- Reactive distillation

All combinations of different technologies can be evaluated as hybrid process solutions with our test equipment, for example:

- The combination of a distillation column with a membrane process

- An extraction process followed by a distillation step to recycle the solvent

- A distillation unit followed by a crystallization step for ultra-purification

As a customer, you are welcome to participate in these tests. The tests are normally conducted on the basis of real-life samples as supplied by our customers.