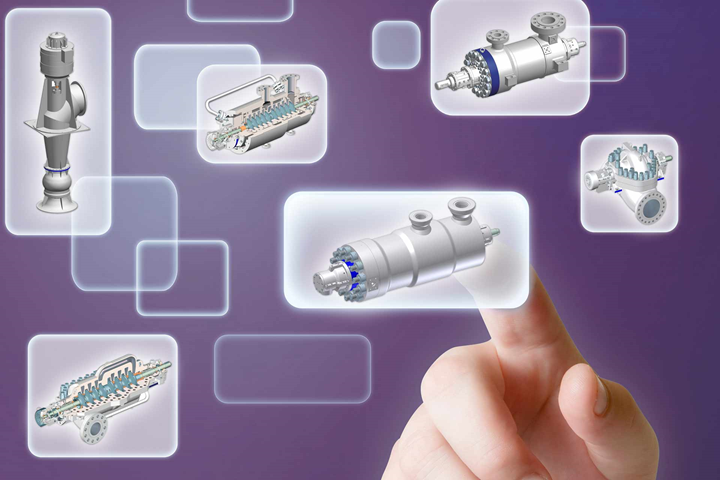

Products

-

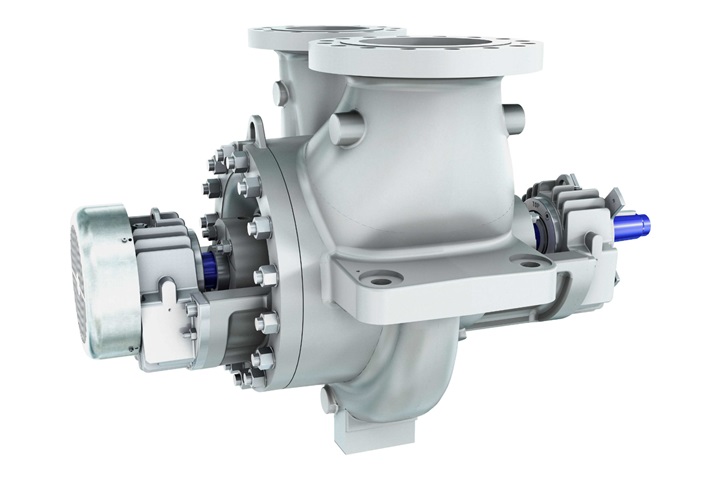

BBS and CD between bearings single stage pumpsThe BBS and CD models are API 610 (ISO 13709) type BB2, single stage, radially split pumps. They offer the widest range of hydraulic performance in the industry.

-

HZB-HTF double suction volute pumpThe HZB-HTF is a horizontal, radially split, single stage, double suction centerline mounted pump. The HZB-HTF are ideal for use in thermal oil applications for handling clean hot and hazardous liquids.

-

OHH overhung single stage pumpsThe OHH is our API 610 (ISO 13709) type OH2 overhung, horizontal, centerline mounted, single stage, radially split process pump.

-

ZE/ZF end suction pump rangeThe ZE/ZF are ideal pumps for arduous industrial applications handling clean, cold or hot liquids, including hydrocarbons and light chemicals.