Products

-

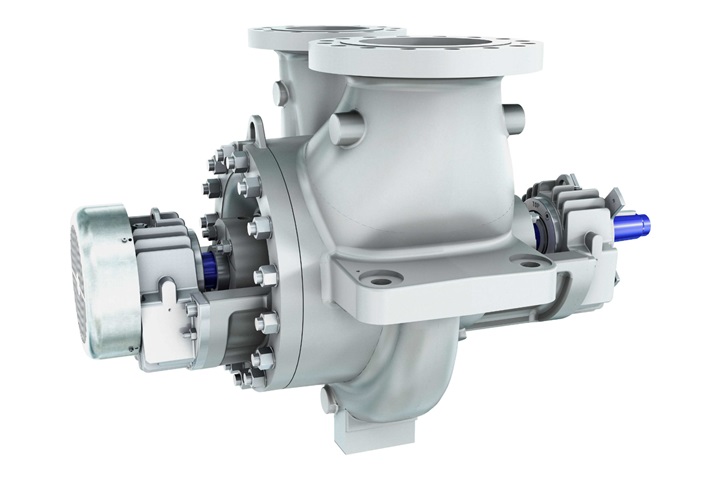

BBS and CD between bearings single stage pumpsThe BBS and CD models are API 610 (ISO 13709) type BB2, single stage, radially split pumps. They offer the widest range of hydraulic performance in the industry.

-

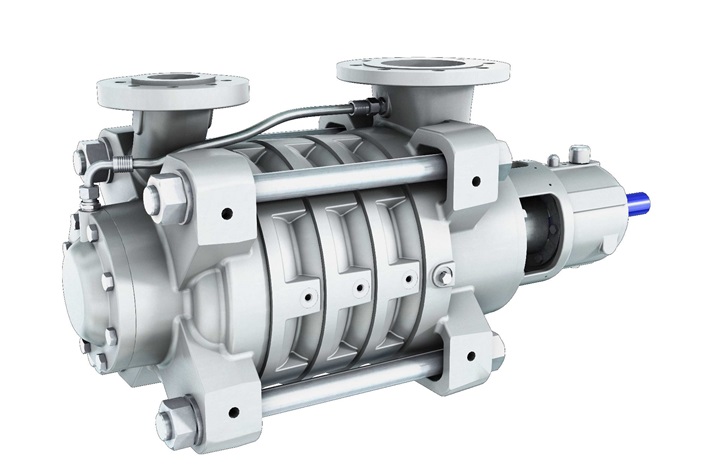

MBN multistage ring section pumpThe MBN pumps are ideal for use in high-pressure applications. They have a big variety of nozzle position options, thus providing flexibility during installation and simplifying the piping design.

-

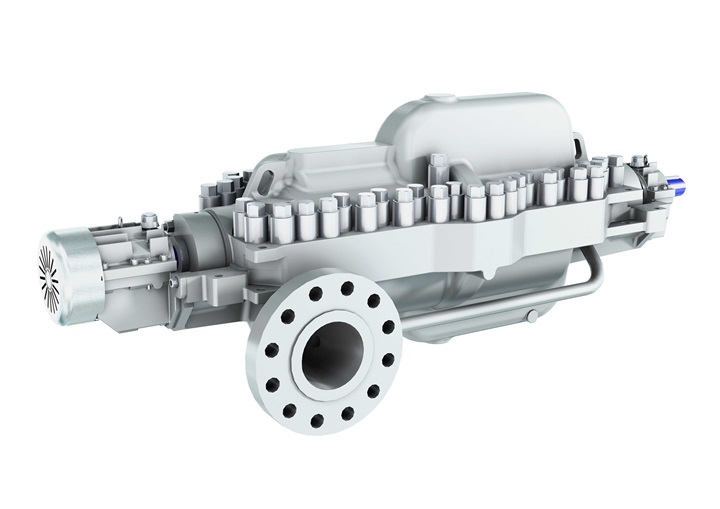

MC high pressure stage casing pumpM-series pumps have a modular design thus allowing Sulzer to find the most efficient solution to meet customer requirements.

-

MSD axially split multistage pumpThe MSD pump has the broadest hydraulic coverage of any BB3 type multistage pump in the market. There are over 10 000 MSD pumps installed in product pipelines, boiler feed, water injection and even nuclear safety-related services around the globe.

-

OHH overhung single stage pumpsThe OHH is our API 610 (ISO 13709) type OH2 overhung, horizontal, centerline mounted, single stage, radially split process pump.