- Increases capacity of separator and gas load factors up to 0.45 m/s

Sulzer Mellachevron™ mist eliminators

Separators for high viscosity liquids

- For high-viscosity liquids

- For applications with risk of fouling due to solid particles

Technology

The Sulzer Mellachevron™ range is divided into a number of categories depending on direction of gas flow and the complexity of the vane profile.

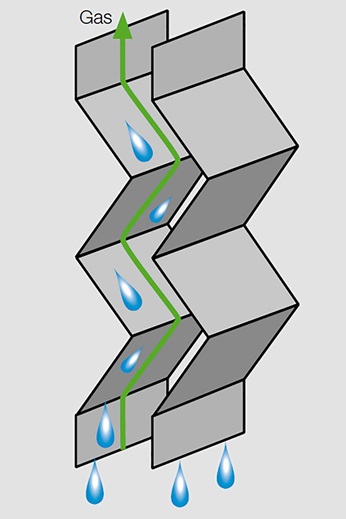

Simple Sulzer Mellachevron™ profiles separate liquid by impingement, coalescence, and drainage on the vane surface with no disengagement of the liquid from the gas stream.

They are particularly suitable for applications with a significant risk of fouling due to solid particles or high-viscosity liquids in the feed, but have relatively low gas handling capacity.

Design

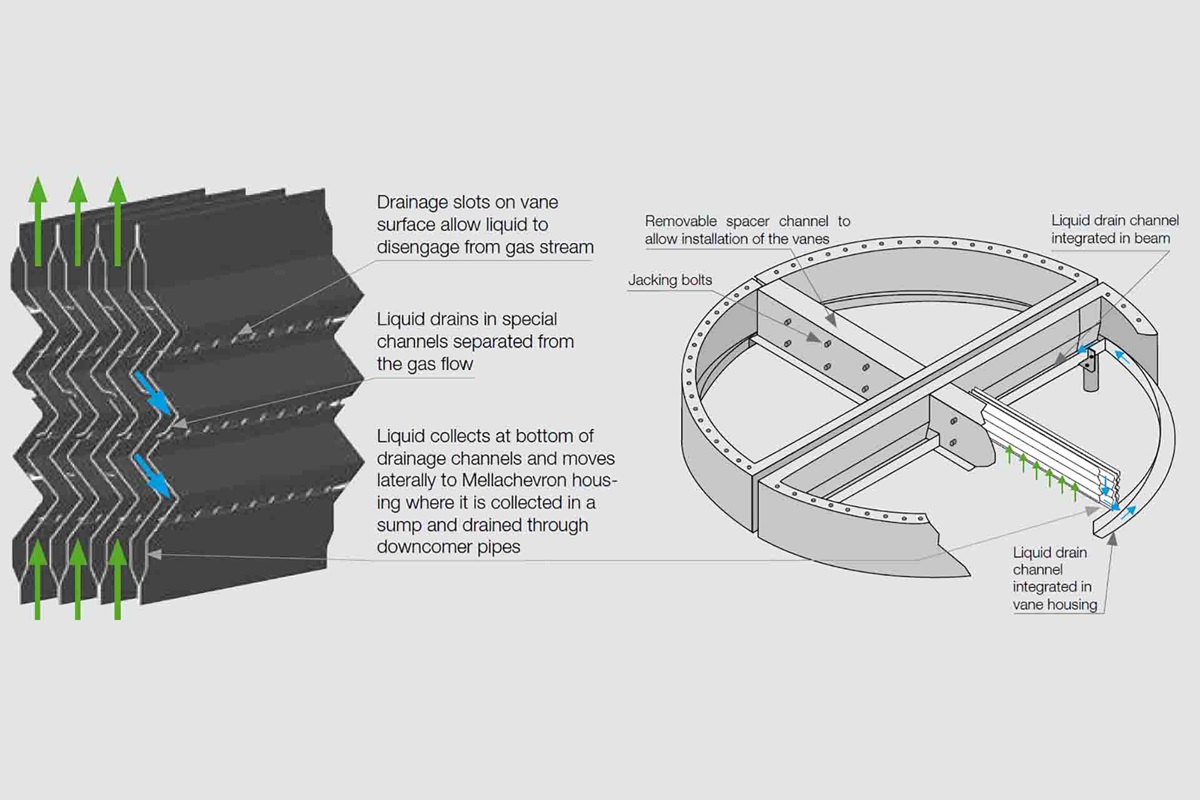

More sophisticated designs provide special separation channels to allow disengagement of liquid and drainage from the vane surface. This increases the capacity of the separator and gas load factors of up to 0.45 m/s are possible. This makes them an excellent choice when equipment size is critical, for example, in offshore applications or for debottlenecking existing equipment.

Complex Mellachevron™ profiles require housings that ensure that the vanes are assembled accurately and provide a liquid sump for drainage of liquid into the vessel or column.

Mellachevron™ designs are available for installation in either vertical or horizontal gas flow. When gas flow is horizontal, the liquid film on the surface of the vane drains vertically downwards into a liquid sump.

Complex Mellachevron™ profiles are used with hooks or drainage channels that help to disengage the liquid from the gas stream and prevent re-entrainment from the downstream face.