- Fiber topology and surface property combined with optimized layer compositions achieve higher efficiency

- Higher loadings and absence of jetting from outer layers result in higher packing densities

- Work well independent of the dispersed phase

- Pressure drop is minimized

- Separation down to 10 ppm free entrainment possible

- Separate systems with interfacial tensions > 2 dyne/cm

- Quick performance recovery following feed condition changes

Dusec™ and Dusec Plus™ Coalescer

Dusec Coalescer cartridges for high separation performance

- Separation of either primary or secondary immiscible liquid dispersions

- Chemical industry

Key characteristics

Dusec Plus Coalescers are designed to achieve high performance with minimum pressure drop, the Sulzer Dusec Plus model provides a high-capacity alternative to conventional Dusec cartridges. The smaller diameter and increased packing density make them suitable for applications where the effective area of the coalescer media in a given vessel has to be maximized.Process

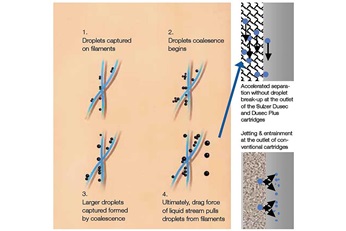

Adhesion forces capture intercepted droplets onto the fiber surface at selective points where clusters form until coalescence takes place and the droplets grow. Viscous drag forces increase until they exceed the adhesion forces, causing the droplets to separate from the fiber and move further into the coalescer fiber bed, where the process is repeated. Eventually the droplets reach primary dispersion size – i.e. predominantly >60 microns. The outer layer of the cartridge is the same composite construction as a Sulzer DC Coalescer, which accelerates separation and avoids jetting and re-entrainment.

Design

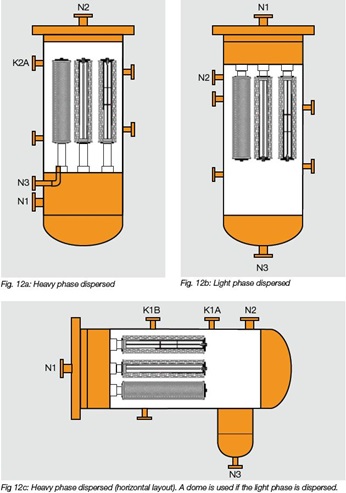

By having a selection of fiber materials arranged in a specific pattern in the cartridge, it is possible to improve the coalescence process significantly by using the phenomena above due to the very high specific surface offered by the fiber material. We can help you to evaluate the number of cartridges and the length of the cartridges that can be fitted into a vessel, and assist you in understanding the installation of the cartridges. The cartridges are available in different length of 500 mm, 1000 mm, and 1500 mm. Each cartridge type has an end cap that can be sealed either by means of a resin in non-corrosive applications or a mechanical sealing that is more resistant to severe services.

Technical specification

We offer a flexible and comprehensive service that includes the design for the complete vessel (including the various nozzle elevations, sizing) and production of additional internals such as weirs and supports, or the mounting plate for Sulzer Dusec and Dusec Plus coalescers.

A large number of mechanically sealed designs have been used in various hydrogen peroxide manufacturing plants. Dusec™ and Dusec Plus™ cartridge coalescers can either be installed in horizontal or vertical vessels.