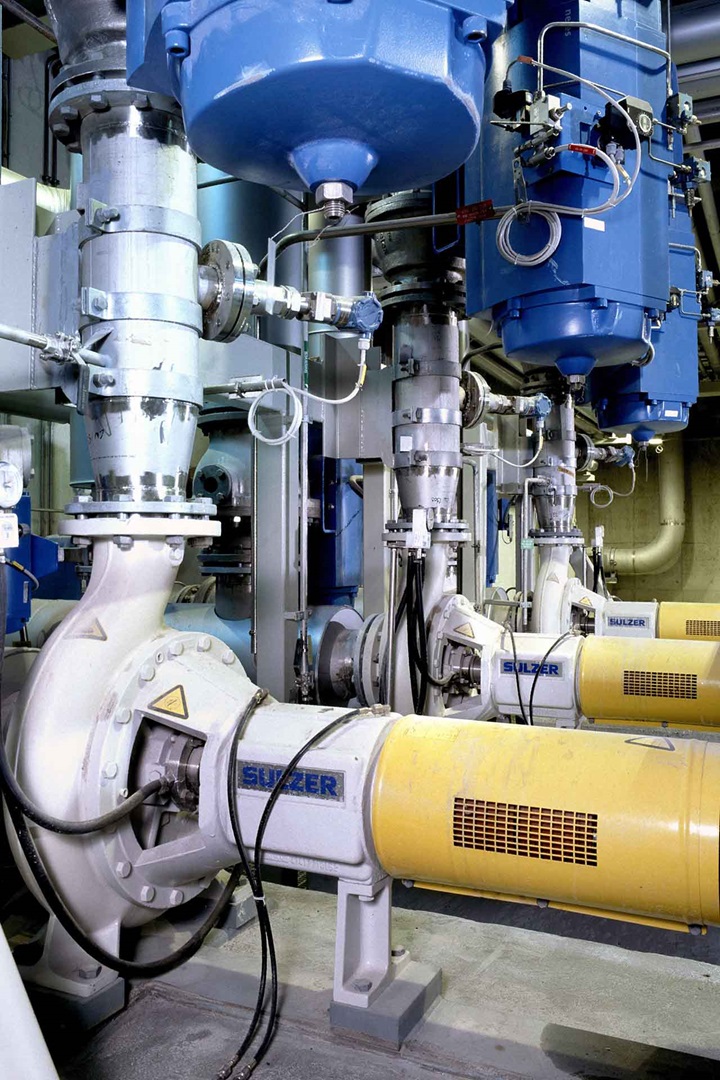

- Long and trusted experience in pulp and paper and other industrial segments

- Excellent performance

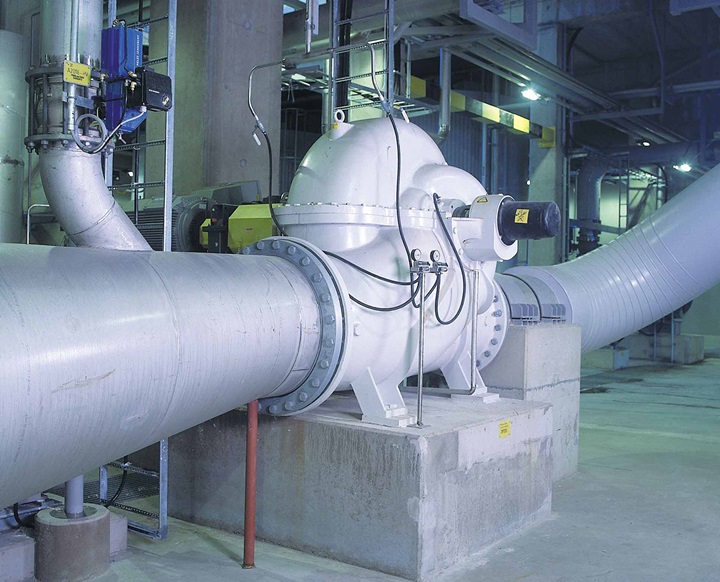

- Energy savings by reducing the head requirement

- Reducing air content

- Creates an efficient mixing zone

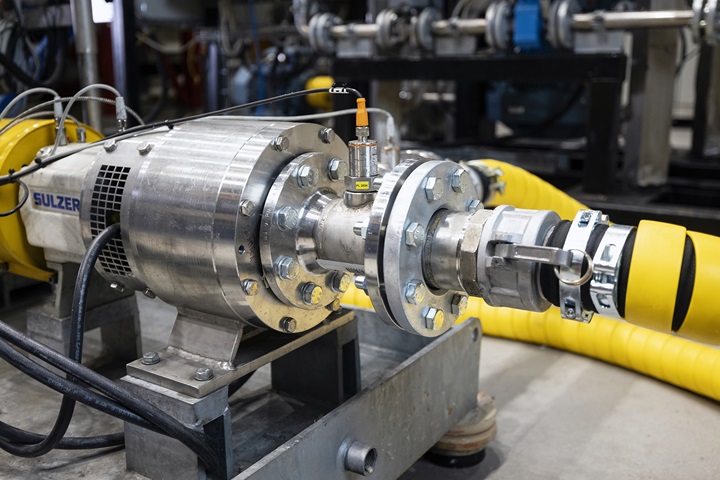

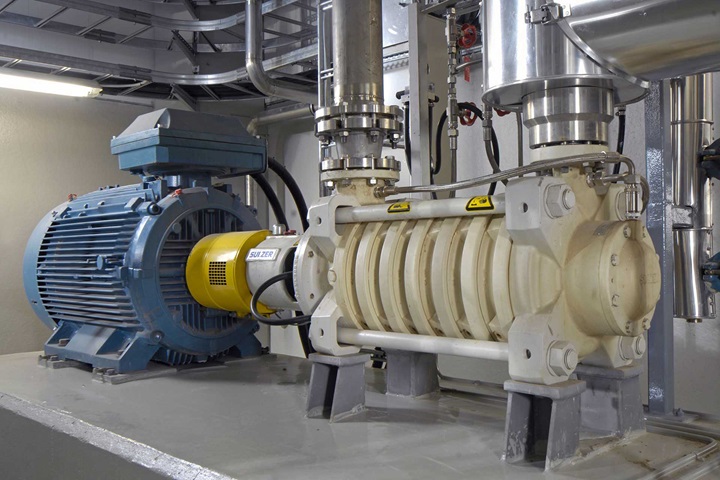

- Unique, patented and superior design features minimize life-cycle costs

SALOMIX VULCA

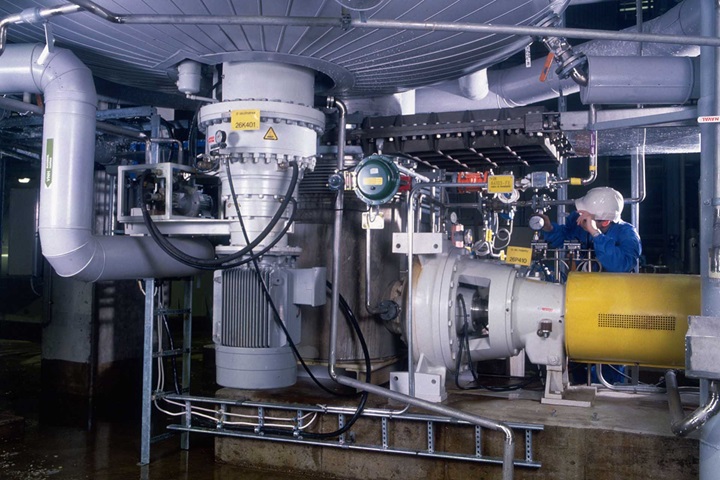

Smart tower management saves energy

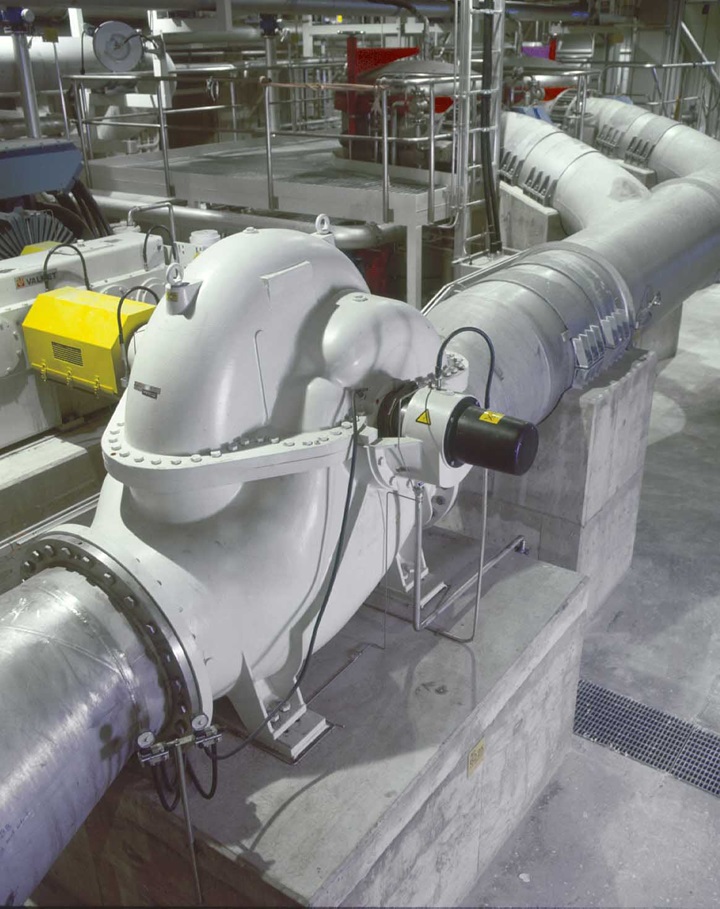

The Sulzer SALOMIX VULCA Tower Management System is a special patented center fillet pillar located at the bottom of the fibrous slurry tower. It ensures effective, high-efficiency and low-cost pumping and prevents mixing of gases into fibrous slurry, while improving the bottom zone mixing process.

- Pumping to pulp mill blow tanks

- Pumping to broke towers

- Pumping to towers, that operate on low pulp levels

- Reliable, effective, high-efficiency and low-cost pumping of fibrous slurry into the fibrous slurry towers

Main design features

- Specially designed column placed at the bottom of a stock tower feeds the tower vertically under pulp level and divides the mixing and storage zones

Key characteristics

| Capacities | Up to tower bottom diameters 12m / 40ft |

| Performance range | The Sulzer SALOMIX Vulca Tower Management System has excellent performance coverage to satisfy the most demanding requirements of pulp and paper tower applications. |