- Solutions for sustainable and cost-efficient production

- Extensive experience in different fields of biofuels and biochemicals

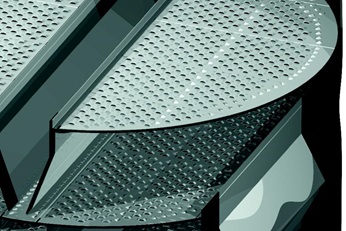

Biofuels and biochemicals

Sustainable and profitable solutions for biofuels and biochemicals

We share your commitment towards a greener environment. Our process solutions are geared to making biofuels and biochemicals both sustainable and profitable.

- For bioethanol

- For biodiesel

- For strong acid hydrolisis

- For edible oil

- For lactic and succinic acid

Key features

Key features

Our process system with heat integration for bioethanol rectification and dehydration offers you low life-cycle costs and a short payback time.

Applications

Sulzer has extensive experience in the following application fields

- Mash / beer column (heavy fouling applications) and rectifier for bioethanol distillation process

- Dehydration of bioethanol by pervaporation / vapor permeation, heat integrated with the overall process

- Liquid-liquid extraction for strong acid hydrolysis route

- Biodiesel: fatty acid methyl ester (FAME) drying, methanol recovery, glycerine drying, glycerine purification

- Free fatty acid removal from edible oil

- Distillation, crystallization and film evaporation technologies for biorefining processes, including production and purification of lactic and succinic acid

Contact the Process plants team