- Plug-and-pump installation without having to worry about overheating.

- Reliable, trouble-free operation also at low water levels.

- High wear resistance ensures years of cost-efficient pumping.

- Modular design increases serviceability and makes it easy to convert the pump for different hydraulic requirements.

Submersible drainage pump J 205

One investment, years of cost-efficient pumping

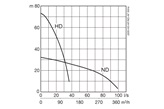

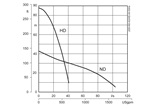

- J 205 ND medium head 3~

- J 205 HD high head 3~

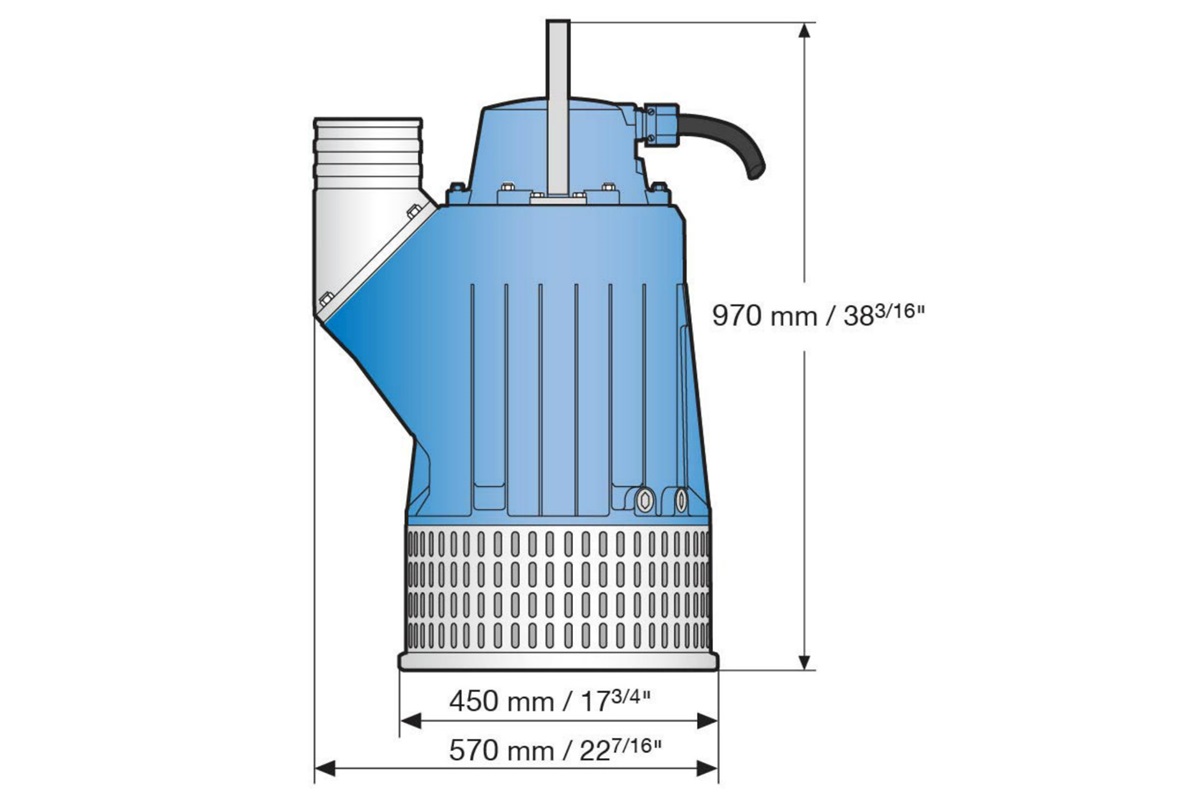

Weight: 155 kg (342 lb)

Motor protection

Built-in thermal switches in the stator windings (140ºC / 284ºF, ±5), connected to built-in contactor, SoftDrive or to separate control box.

DI leakage sensor, but not in combination with built-in contactor or SoftDrive.

Discharge connections

4” (standard HD), 6” (standard ND), 8” hose connections

4”, 6”, 8” G/B.S.P. threaded connections

4”, 6”, 8” NPT threaded connections

Storz coupling available as an accessory

Plug-and-pump installation

Plug in without having to worry about overheating. Built-in contactor connected to the thermal sensors protects the motor from overheating.

Wear resistance

One investment for years of cost-efficient pumping. Impeller in high chrome alloy steel ensures a long lifetime and high efficiency.

Reliable operation - minimizes maintenance time

Double outer casing and good heat convection enable the pump to operate continuously at low levels or even run dry without damaging the motor.

Serviceability

Save time and money with easy on-site service. Modular design lowers the overall service costs. By removing the top cover of the pump, you can easily check the electrical junction box. Environmentally safe white oil is used in the oil casing for easy inspection of seal conditions.

| Electric submersible pump | J 205 |

| Maximum submergence | 20 m |

| Protection class | IP 68 |

| Max. temperature of pumped medium at max. power input and continuous duty | 40ºC |

| Max. media density | 1,100 kg/m3 |

| pH of the pumped medium | 5-8 |

| Strainer hole | 8 x 34 mm |

| Max number of starts | 30/hour |

| Motor rating P2 | 21 kW |

| Speed | 2,910 rpm |

| Power cable | 20 m type H07RN8-F |

| Electric submersible pump | J 205 |

| Maximum submergence | 20 m |

| Protection class | IP 68 |

| Max. temperature of pumped medium at max. power input and continuous duty | 40ºC |

| Max. media density | 1,100 kg/m3 |

| pH of the pumped medium | 5-8 |

| Strainer hole | 8 x 34 mm |

| Max number of starts | 30/hour |

| Motor rating P2 | 26 kW |

| Speed | 3,500 rpm |

| Power cable | 20 m type H07RN8-F |

| Electric submersible pump | J 205 |

| Maximum submergence | 65 ft |

| Protection class | IP 68 |

| Max. temperature of pumped medium at max. power input and continuous duty | 104ºF |

| Max. media density | 0.0397 lb/inch3 |

| pH of the pumped medium | 5-8 |

| Strainer hole | 5/16" x 1 5/16" |

| Max number of starts | 30/hour |

| Motor rating P2 | 35 Hp |

| Speed | 3,500 rpm |

| Power cable | 65 ft AWG |