- Short residence time

- Low liquid hold-up

- Very low pressures

- Very low pressure drop

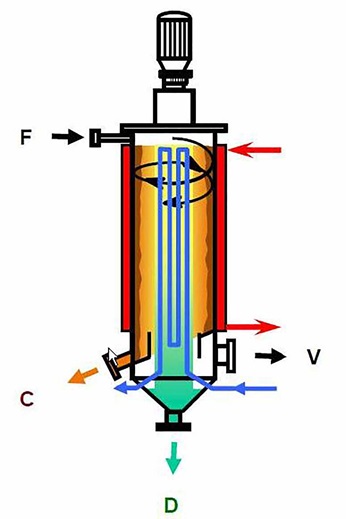

Short path evaporator

Low pressure evaporation solutions

- For concentration and purification of extremely heat-sensitive products

- For distillation of components with very high boiling points

Technology

In a similar way to a wiped film evaporator, the product film is agitated by a rotor on the inner wall of the vessel. The vapors are generated by heat input from the wall to the film. These vapors migrate to the central condenser where they are condensed as “Distillate” (D). This distillate flows down the tubes of the condenser and leaves the evaporator from the bottom nozzle. The fraction of the film that reaches the bottom of vessel is called “Concentrate” (C). It is collected at the bottom of the shell.

Process security

To ensure reliable equipment design and to verify that the desired process performance meets your product specifications, we test your individual process in our pilot plant facilities. If you prefer, we can provide you with mobile test equipment on a rental basis to apply in tests at your own facilities.

Contact the Process plants team