- Replacing two progressive cavity pumps operating on produced water service at Apache / Quadrant Energy Devil's Creek gas plant, North Western Australia with centrifugal pumps

- Preventing internal rubber stator to swell and pumps to seize when in standby mode because of aromatic gases in the produced water

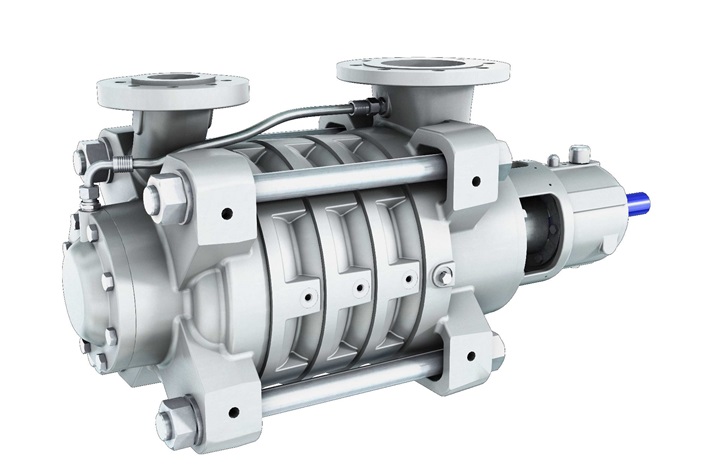

Devil's Creek gas plant, hydro-cyclone feed pumps

Reduce maintenance and increase availability

Sulzer replaced two progressive cavity pumps at Devil's Creek gas plant with Sulzer MBN pumps for high resistance to aromatic gases in the produced water.

- Supplying Sulzer MBN centrifugal pumps with Kalrez O rings for high resistance to aromatic gases, in duplex (41) MOC for produce water and slow speed for 'low shear' operation due to oil in the fluid

- Customer had the options of API 610 BB5 design pump or ISO 5199 design (ring-section)

- Due to application, budget, and short delivery period, the Sulzer MBN pump was selected

The pumps are operating satisfactorily. They are only run about once every three weeks for a shift at the moment until the water rate increases years down the track. Based on this short period of operation, the production team on-site is very happy with the upgrade.

Quadrant Facilities Engineer

- MBN pumps have reduced maintenance and increased availability

- MBN pumps provide a smaller foot print for maintenance maneuverability

Your contact