- Cooking

- Washing

- Screening

- Oxygen delignification

- Bleaching

- Storage.

Chemical pulp fiber line

Unique applications coverage for chemical pulp fiber line

Proven pumping, mixing and agitation solutions for your cooking, washing, screening, oxygen delignification, bleaching, and storage processes to ensure process reliability, high efficiency, and low operating costs.

- Digester feed and circulation - AHLSTAR™ EPP/T Range

- Black liquor pumping - AHLSTAR™ A Range

- Stock pumping - AHLSTAR™ A Range

- Digester liquor feed - LSP/LST High-pressure low speed

- Soap pumping - AHLSTAR™ A Range

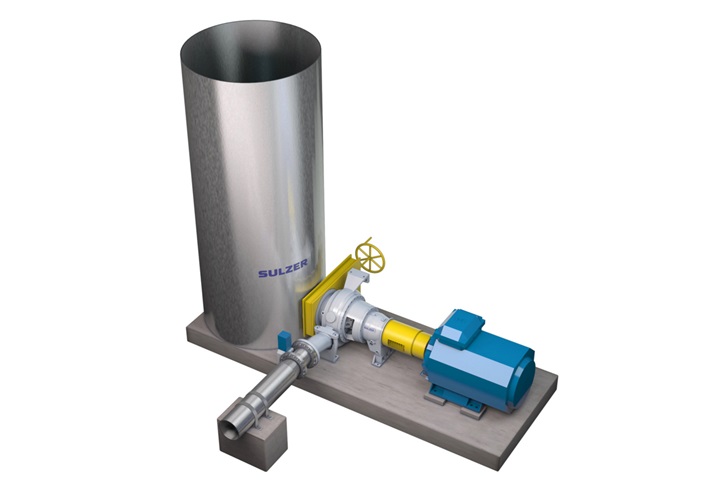

- Medium consistency (MC™) stock pumping and transfer - MC™ Pumping System

- Semi-MC™ consistency range washer feed – KCE-, AHLSTAR™ A Range

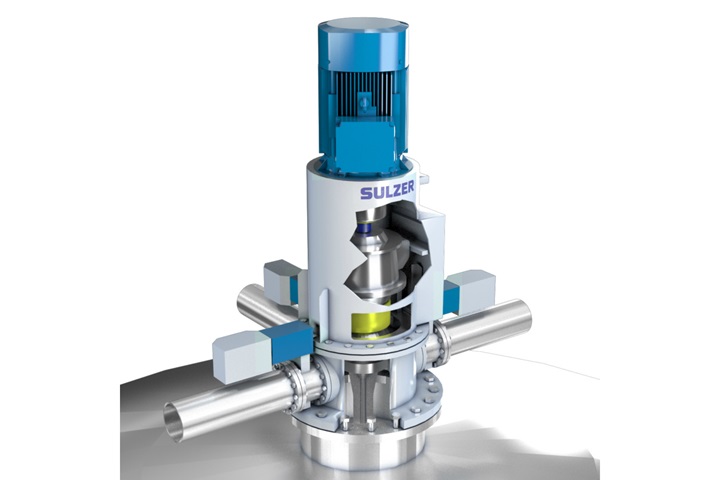

- Chemical mixing into stock - SX Chemical Mixer

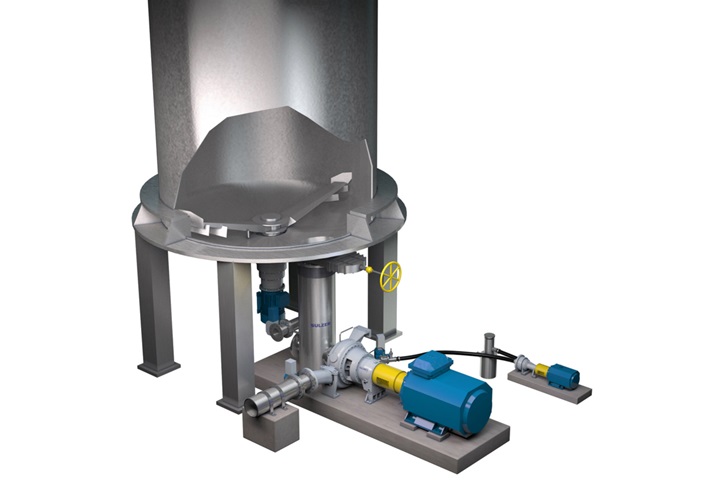

- Tower discharge pumping systems - MC™ Discharge Scraper

- Pumping and controlled flow splitting- MC™ Discharger

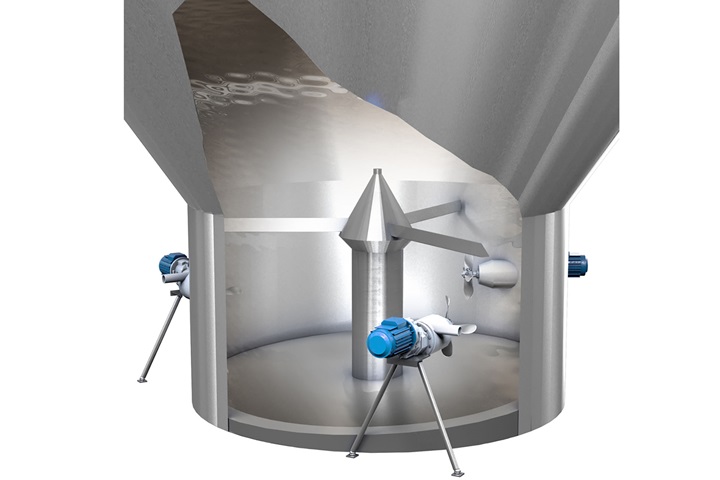

- Agitation and mixing of stock/other liquids in tanks and towers - SALOMIX™ SSA, SALOMIX™ SSF

- Charging or discharging of stock towers - SALOMIX™ TES, GLI and VULCA

Products

-

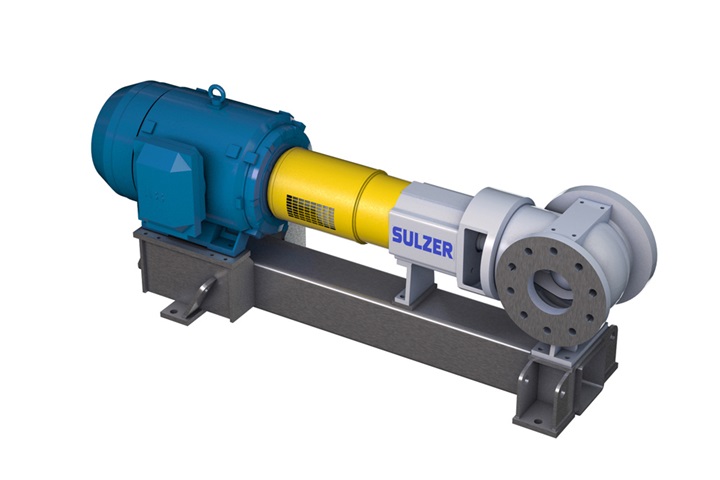

AHLSTAR A process pump rangeAHLSTAR A end-suction single-stage centrifugal process pumps are used for demanding industrial applications to ensure process reliability, high efficiency and low operating costs. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR APT process pump rangeAHLSTAR APT end-suction single-stage centrifugal process pumps are used for demanding industrial applications to ensure process reliability, high efficiency and low operating costs. The pump exceeds the requirements of ISO 5199.

-

AHLSTAR EPP/T high-temperature process pump rangeAHLSTAR EPP/T centerline supported end-suction single-stage centrifugal process pumps are designed to stand high temperature especially in demanding industrial hot liquid pumping applications. The pump exceeds the requirements of ISO 5199.

-

KCE pumping systemsKCE™ medium-consistency centrifugal pumps are mostly used in wash press feed applications to pump semi-medium consistency pulp up to 8 % and for high volume flows.

-

MC discharge scraperMedium-consistency discharge scrapers are used for discharging high-consistency fibrous slurry towers to ensure process reliability, high efficiency, and low operating costs.

-

MC dischargerMedium-consistency dischargers are used for dividing and controlling high-consistency pulp flow and for discharging high-consistency towers and reactors.

-

MCE pumping systemsMCE™ medium-consistency centrifugal pumps are used for demanding medium-consistency pulp applications up to 18% consistency to ensure process reliability, high efficiency, and low operating costs.

-

SALOMIX GLISulzer SALOMIX GLI Tower Management System is a special patented center fillet located at the bottom of the high-consistency fibrous slurry storage tower. It ensures an effective, high-efficiency and low-cost mixing and dilution process, while generating a stable consistency discharge flow.

-

SALOMIX TES top entry spreaderSulzer SALOMIX TES Top Entry Spreader spreads high-consistency fibrous slurries evenly on the top surface of the tower to control the flow in the upper, high-consistency part of the tower and to stabilize and homogenize the discharged fibrous slurry flow from the lower part of the tower.

-

SALOMIX™ SSA side-mounted agitatorsA robust, belt-driven agitator for light to heavy duties. Agitator performance can be adjusted through other drive combinations. Features the new high-efficiency EX3 propeller.

-

SX chemical mixerSX dynamic chemical mixers are used for mixing gases or chemicals into pulp or other type of process liquids in demanding industrial applications.

Documents

Brochures

Technical articles

Related links

-

Pump servicesReliable and efficient pump operation is critical for your business. Therefore you need a service partner that can respond fast and flexibly. Our pump services are second to none and provide solutions that help you to improve your processes and business performance.

-

Original pump spare partsOriginal spare parts machined to the correct tolerances and clearances give a perfect fit first time, every time. Our commitment to continuous improvement often allows us to supply parts with improved features, thus enhancing performance, extending equipment life, while reducing maintenance costs.

-

Service kitsWhen your equipment needs to be repaired you shouldn’t have to worry about spending valuable time searching for the right parts – or even worse, finding out that some small but vital parts are missing. With Sulzer service kits you get everything you need in one package.

-

Sulzer mechanical sealsSulzer mechanical seals are strong by design and have been proven very reliable in various pumping applications.

-

Service centers for rotating equipmentFind the service center nearest to you. With more than 100 service centers worldwide, we are always close to the customer.