Innovation Award 2018 winner

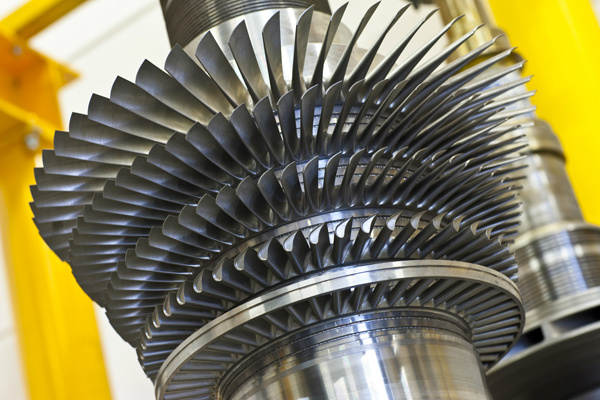

September 07, 2018Extending steam turbine lifetime with 12Cr weld

Fast repair of critical rotating components is one of the main activities of the Rotating Equipment Services division of Sulzer. It is important for Sulzer to support the Power generation industry with high-quality products and services. Most of the power generation in the Asia-Pacific comes from steam turbines — in coal plants or in gas combined cycle plants. But another important energy source is renewable geothermal steam from underground.

Geothermal steam turbines work with steam that contains some very corrosive components, which are also variable and unpredictable because it is a natural process. In practice, very substantial damage can occur over time due to corrosion and erosion, which can cause the areas exposed to the steam to be “washed away.” The rotors used for these steam turbines employ a range of steels specially developed to have strength over a long operating life of 25 or even 30 years and be corrosion resistant.

To set Sulzer apart from original equipment manufacturers, who often propose very costly new rotors, the Sulzer team saw a market opportunity to repair the rotors by welding. In this process, an area of damaged material is removed and a large mass of weld material is used to replace it. The geometry is then recreated to finish the renovated rotor. This can be much quicker than ordering a replacement part because the long lead-time for new forgings can be avoided. The customer benfits from the improved cost structure.

Eesan Vamadevan

Winning this innovation award means a high appreciation from Sulzer for the creative and innovative work we have done. It motivates us to keep challenging the impossible with focus on customers

The idea was born in 2013, when Sulzer Indonesia had a geothermal steam turbine rotor repair project from a Philippines customer involving cracks and stress corrosion. The customer then requested improvements to avoid any recurrence in the future.

There was some concern within the team about the weld material used at that time — a low alloy weld wire for turbine rotor material typically has a high nickel content, which is likely to suffer corrosion cracking when exposed to a hostile environment. Hepy and the team in Indonesia consulted with Eesan from Sulzer in the US and eventually came up with the 12% chromium steel (12Cr) weld wire option, which provides better resistance than the original materials in many cases.

Welding 12% chromium steel material onto the various base materials required in the process is quite a difficult feat. Hepy and Eesan have succeeded in developing the process and have already implemented the repair in rotors shipped to customers on site.

Hepy Hanipa

I feel great because the hard work we did is creating significant results for both Sulzer and customers. I feel proud that I can help our customers to save money.

Why this is significant for our customers?

The 12Cr weld has even greater corrosion resistance than similar alloys developed by the different rotor suppliers in the specific hostile environment where the geothermal steam is extracted from the rock. This means that in some cases, the 12Cr weld can actually give the renovated rotor an improved life over the original material.