Assisting separating and mixing processes

Saving you time is what drives our design

Designing an efficient intervention

When a refinery turnaround has to be performed at intervals of two to five years, we recognize an opportunity to bring the latest technology to your operations. We know that equipment in constant operation wears down over time. This is our chance to replace column and separator internals with products that bring you greater efficiency. We take pride in our experienced service personnel, who are trained to isolate, open, inspect, modify, repair, and close columns as quickly as possible. However, we know that our response can be even more effective with well-designed column internals.

Systems that allow us to work at twice the speed

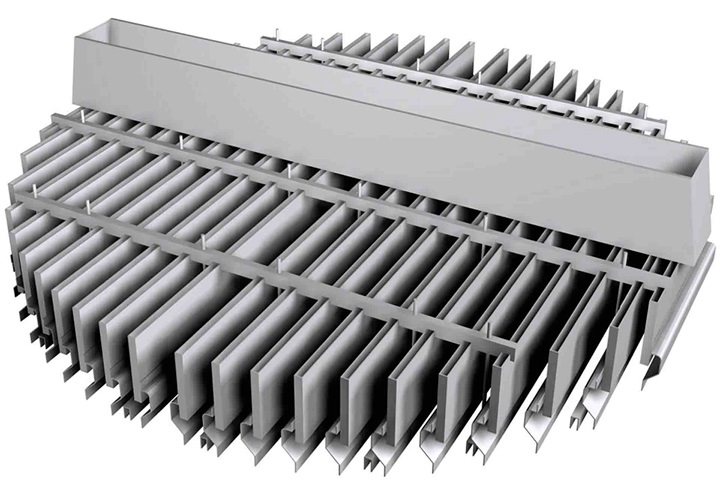

Sulzer integrates several features that can reduce column shutdown time. One particularly time-consuming process involves removing and replacing separation trays. This is not only because of the enormous size of the trays but also because the different tray panels need to be connected to each other. Sulzer offers boltless panel-to-panel connections called Lip-Slot™. The interlocking tray panels can be quickly secured to each other with a click system instead of having to bolt the panels together. This special design reduces the time needed to install the equipment by up to 50%. This means that our service teams can install 2 Lip-Slot trays in the time it normally takes to install 1 conventional tray.

Our special design reduces the time needed to install the equipment by up to 50%.

Systems that allow us to work at twice the speed

Sulzer integrates several features that can reduce column shutdown time. One particularly time-consuming process involves removing and replacing separation trays. This is not only because of the enormous size of the trays but also because the different tray panels need to be connected to each other. Sulzer offers boltless panel-to-panel connections called Lip-Slot™. The interlocking tray panels can be quickly secured to each other with a click system instead of having to bolt the panels together. This special design reduces the time needed to install the equipment by up to 50%. This means that our service teams can install 2 Lip-Slot trays in the time it normally takes to install 1 conventional tray.

Getting to the problem: our manways make access 5 times faster

There can be as many as 100 separation trays inside a column. To inspect each individual tray, our teams need to climb through a small opening in the tray called the manway. To open a conventional manway the team must unbolt several screws. Depending on the size of the column or the tray, it can take up to 15 minutes to achieve access.

Sulzer provides quick-opening manways that allow access to the tray in less than 10 seconds. Our manways come with handles and special locks that allow them to be opened and closed without losing tightness between the manway panels. The panels can be opened or closed from either the top or the bottom of the tray. If service employees need to access 20 trays, this quick-opening system allows inspection to be completed within 1 hour. With conventional manways, it would take them about 5 hours. Such time-saving innovation significantly reduces shutdown time, allowing your operations to resume as quickly as possible.

Sulzer provides quick-opening manways that allow access to separation trays in less than 10 seconds.