- Plug-and-pump installation without having to worry about overheating.

- Clog-free pumping with free-flow vortex impeller and pump volute.

- High wear resistance ensures years of cost-efficient pumping.

- Slim design and low weight make the pump easy to move and handle.

- Serviceability with modular design.

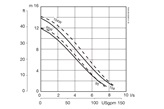

- Non-overloading performance with two different impellers for each pump model. The small impeller allows the pump to run in low-level applications.

Submersible sludge pump JS 12

Making your life easier

- JS 12 W/WKS* -104** 1~ 50 Hz

- JS 12 W/WKS* -114 1~ 50 Hz

- JS 12 D/DKS* -104** 3~ 50 Hz

- JS 12 D/DKS* -114 3~ 50 Hz

*Option: built-in float switch, excl. 500 V

- JS 12 W/WKS* -95** 1~ 60 Hz

- JS 12 W/WKS* -104 1~ 60 Hz

- JS 12 D/DKS* -95** 3~ 60 Hz

- JS 12 D/DKS* -104 3~ 60 Hz

* Option: built-in float switch, excl. 575 V

**Impeller diameter for duty with low water level or intermittent dry running

Max. impeller diameter requires half motor or more submersed for continuous duty. (Pump can operate lying down).

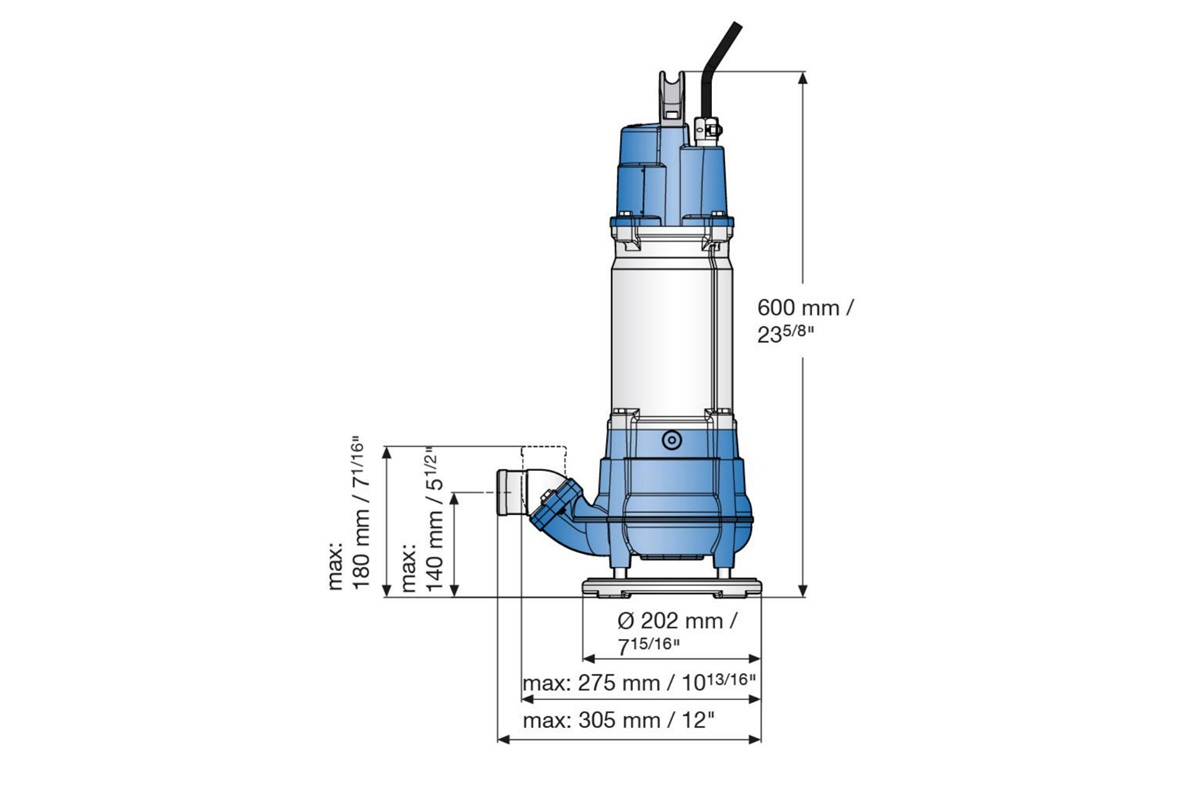

Weight: D: 19 kg (42 lb), W: 20 kg (44 lb)

Motor protection

|

Built-in thermal switches in the stator windings (140ºC / 284ºF, ±5) |

Discharge connections

|

2” (standard), 2½”, 3" hose connections |

| 2", 2 1/2", 3" G/B.S.P. threaded connections |

|

2”, 3" NPT threaded connections |

Storz coupling available as an accessory

Plug-and-pump installation

Plug in without having to worry about overheating. Built-in thermal protection protects the motor from overheating.

Clog-free pumping – avoid downtime with solid-proof hydraulics

Free-flow vortex impeller and pump volute make the sludge pump perfect for pumping solids.

Reliability and wear resistance

One investment for years of cost-efficient pumping. Impeller and pump housing are made from wear-resistant ductile iron. Vortex hydraulics minimize load on the shaft and bearings, which ensures reliable operation and maintained efficiency. Double mechanical shaft seal in oil bath with the primary seal in silicon carbide ensures safe operation and long life.

Convenient handling – designed to make your life easier

The motor parts in lightweight aluminum make the pump very easy to handle and install.

Serviceability

Save time and money with easy on-site service. Modular design lowers the overall service costs. Easy access to the electrical junction box.

| Electric submersible pump | JS 12 |

| Maximum submergence | 20 m |

| Protection class | IP 68 |

| Max. temperature of pumped medium at max. power input and continuous duty | 40ºC |

| Max. media density | 1,100 kg/m3 |

| pH of the pumped medium | 5-8 |

| Free passage | diam. 40 mm |

| Max number of starts | 30/hour |

| Motor rating P2 | 0.9 kW |

| Speed | 2,770 rpm |

| Power cable | 20 m type H07RN8-F |

| Electric submersible pump | JS 12 |

| Maximum submergence | 20 m |

| Protection class | IP 68 |

| Max. temperature of pumped medium at max. power input and continuous duty | 40ºC |

| Max. media density | 1,100 kg/m3 |

| pH of the pumped medium | 5-8 |

| Free passage | diam. 40 mm |

| Max number of starts | 30/hour |

| Motor rating P2 | 1.1 kW |

| Speed | 3,360 rpm (1~), 3,380 rpm (3~) |

| Power cable | 20 m type H07RN8-F |

| Electric submersible pump | JS 12 |

| Maximum submergence | 65 ft |

| Protection class | IP 68 |

| Max. temperature of pumped medium at max. power input and continuous duty | 104ºF |

| Max. media density | 0.0397 lb/inch3 |

| pH of the pumped medium | 5-8 |

| Free passage | diam. 1 9/16" |

| Max number of starts | 30/hour |

| Motor rating P2 | 1.5 Hp |

| Speed | 3,360 rpm (1~), 3,380 rpm (3~) |

| Power cable | 65 ft type AWG |