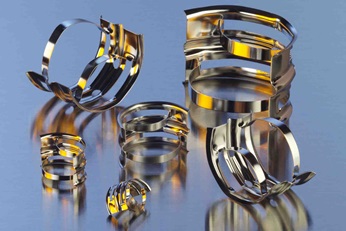

- Conventional rings for a wide application range

- Different geometries and materials available

- Ease of replacement and storage

- Ideal choice for systems with heavy fouling or corrosion

Conventional random packings

Wide portfolio of rings for your needs

Our extensive portfolio offers traditional and high-performance random packing’s including Nutter Rings™, I-Rings™, C-Rings™, P-Rings™, R-Rings™ and S-Rings™.

- For fractionation, absorption and stripping operations

- For gas, refinery and chemical plants

Nutter Ring

Nutter Ring™

Nutter Ring™

- High-performance random packing designed by Dale Nutter in 1984

- Efficiency is enhanced by lateral liquid spreading and surface film renewal

- Superior surface utilization allows for shorter packed beds

- Extensively tested by the Fractionation Research Institute (FRI), making the Nutter Ring one of the best known high-performance random packings

- Geometry provides maximum randomness with minimum nesting and maximum mechanical strength

I-Ring

I-Ring™

I-Ring™

- Equivalent to the Intalox Metal Tower Packing (IMTP), the industry‘s first and most widely used high-performance random packing introduced in the late 1970's

- Geometry ensures low liquid hold-up and a significant improvement in capacity compared to Pall rings

C-Ring

C-Ring™

C-Ring™

- Equivalent to the widely used Cascade Mini-Ring (CMR)

- Evolution of Pall ring employing a much lower diameter-to-height ratio favoring orientation that results in lower pressure drop and higher capacity

- Excellent mechanical strength

- C-rings excel within random packing in fouling media

Plastic C-Ring

Plastic C-Ring™

Plastic C-Ring™

- Equivalent to the Plastic Cascade Mini Ring (CMR)

- Better capacity & efficiency than Pall Ring with low aspect ratio of 1:3 (height/diameter)

- Lower pressure drop

- Available in PP, PVC/C, PE, PVDF, ETFE, PFA

P-Ring

P-Ring™

P-Ring™

- Equivalent to the widely used Pall ring

- Designed by BASF AG around 1940 based on the Raschig ring

- Punched “shovels” leave “windows” on the outside, facilitating vapor flow and increasing capacity compared with the R-Ring

- Extensively tested by research institutes worldwide

Plastic P-Ring

Plastic P-Ring™

Plastic P-Ring™

- Equivalent to Plastic Pall Ring

- The most common plastic random packing type used in industry

- Available in PP, PVC/C, PE, PVDF, ETFE, PFA

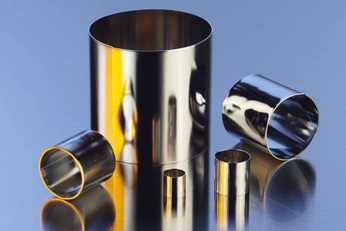

R-Ring

R-Ring™

R-Ring™

- Equivalent to the widely used Raschig ring

- Employing a diameter-to-height ratio of ~1 makes the Raschig ring the first “designed” random packing, introduced by Fritz Raschig at the end of the 19th century

S-Ring

S-Ring™

S-RingTM

- 100% equivalence to Raschig Super-Ring, a well introduced ring type in the petrochemical industry

- One of the first so called high-performance rings

- Well established in a number of licensed process technologies

- Alternating wave structure prevents entanglement of individual pieces