Brochures

-

Mechanical ServicespdfLanguages:

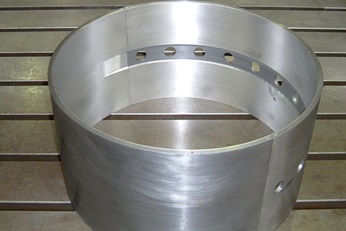

Our engineers can offer upgrades to lube oil systems or bearing geometry to help resolve repetitive failures.

White metals/babbitts have long been used as an anti-friction material for bearing linings. Applications include:

The quality of the replacement white metal/babbitt depends on preparation, top-class quality control procedures, and experience. We rely on our experience to select the optimum grade of white metal for the job, and to cast the white metal. We use new metal for every job in order to ensure top quality.

Talk or write to our experts to find your best solution.