- Maximum safety due to double casing design. Pipework connections remain undisturbed during disassembly

- High-strength barrel material to resist thermal shock

- Full cartridge pull-out for rapid changeover

- Design features that eliminate the need for pre-warming in most installations except on large size

- Long operating life regardless of the operating mode

HPT high pressure barrel casing pump

Built to take on the pressures of your industry

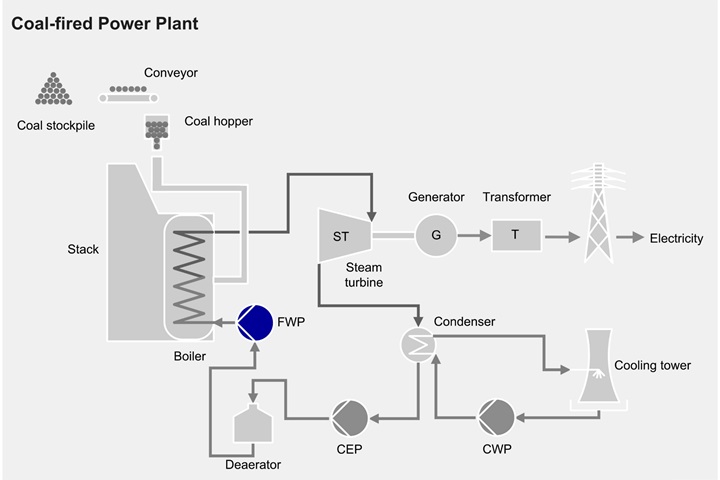

The HPT is a pump specifically designed for boiler feed applications in thermal power stations. The pumps are optimized to provide high-efficiency operation over an extended period of time, thus reducing operating and maintenance costs.

- Main boiler feed in thermal power stations

Main design features

- Barrel design incorporates many design features resulting from Sulzer/EPRI research contract

- Axial thrust compensation by balance piston to avoid damage during transient conditions

- Fully rated double-acting tilting pad thrust bearing

- Radial grooves for increased radial stiffness, reduced effect on rotor tilting, and good rotor dynamic behavior

- Swirl break at balance piston to maintain rotor stability, even when the running clearances are worn

Key characteristics

| Capacities | Up to 4,000 m3/h / 17,600 US gpm |

| Heads | Up to 4,200 m / 13,800 ft |

| Pressures | Up to 545 bar / 7,905 psi |

| Temperatures | Up to 220°C / 430°F |

| Discharge sizes | Up to 500 mm / 20 inches |

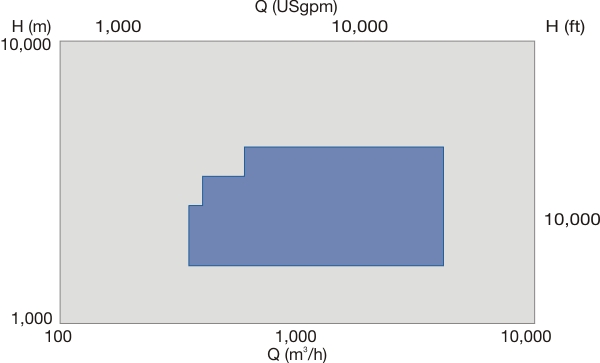

Performance range

Performance range