HST™ 30 high-speed turbocompressor

A turbocompressor that delivers on the highest efficiency

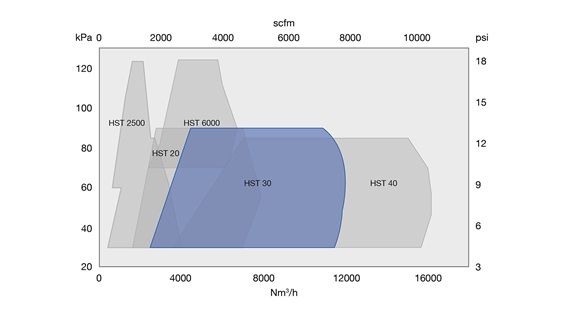

The HST™ 30 is the newest addition to the HST™ line of high-speed turbocompressors. It offers more flow and pressure at a significantly higher efficiency than its predecessors do. This translates into big savings in the energy consumed by low-pressure air compression, both in wastewater treatment and industrial processes.

Get in touch!

Edward Paro

Portfolio Manager Compressors and Aeration

We are eager to discuss your business needs and answer any questions you may have.

Features

1 Magnetic bearings

- No other solution offers the same efficiency, stability or component life

- The condition of the machine is continuously monitored

2 State-of-the-art control and monitoring

- Integrated control unit with touch screen ensures ease of operation and good feedback on performance

- Smart connection to upper-level automation is possible, as well as remote monitoring

3 Integrated package

- The turbocompressor is designed for ease of installation and operation, with motor silencer, cabinet silencer and a silenced blow-off valve

incorporated into the cabinet - Complexity is reduced, along with the cost of installation

Benefits

4 High overall efficiency

- An excellent combination of superior, well proven designs ensures energy savings and lower lifecycle cost

5 Superior low-noise operation

- Silent operation is integrated into the design early on

- Quiet running means a better working environment for employees and less noise pollution in the plant vicinity

6 Suitable outer dimensions

- The turbocompressor fits well into most existing compressor rooms, making it easy to replace older, inefficient solutions

- The compact and integrated design reduces costs when planning new installations

7 Safety built-in and pre-approved

- The turbocompressor has been designed for total conformity with all relevant standards

- Product versions available for compliance with UL/CSA and CE requirements

Main applications

The HST 30 turbocompressor is highly suitable for the following fields of application:

- Aeration of water, wastewater or other liquids

- Floatation by air

- Supplying air to combustion processes

- Desulfurization

Technical information

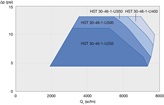

| Operating data | HST 30 - 36 | HST 30 - 46 |

| Airflow range |

2’400 - 9’800 Nm³/h 1’500 - 6’200 SCFM |

3’000 - 12’300 Nm³/h 1’900 - 7’800 SCFM |

| Pressure rise |

30 - 90 kPa 4 - 13 PSIG |

30 - 90 kPa 4 - 13 PSIG |

| Maximum input power |

190 - 300 kW 250 - 400 hp |

190 - 300 kW 250 - 400 hp |

| Power supply |

380 - 690 V 480 or 580 V (400 - 600 V) |

380 - 690 V 480 or 580 V (400 - 600 V) |

| Input frequency | 50 - 60 Hz | 50 - 60 Hz |

| Protection class |

IP33D NEMA 12 |

IP33D NEMA 12 |

| Thermal motor protection | PT 100 | PT 100 |

| Maximum noise level | 72 - 73 dB | 72 - 73 dB |

| Permitted chemical vapors | IEC 60721-3-3 class 3C3 | IEC 60721-3-3 class 3C3 |

| Approvals | CE, UL, CSA | CE, UL, CSA |