- Cost-efficient process

- Weld overlay is maximizing operational availability and performance

- High quality welding due to automated weld overlay

- Welding with controllable and consistent parameters

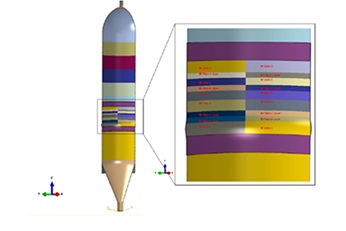

Tower and vessel automated weld overlay

Get worn areas restored with weld overlay

- Tower/column

- Vessel

- Coker drum

- Separator

Tower and vessel shell overlay repair and corrosion protection

Utilizing advanced automated welding equipment our teams can repair corroded or eroded areas by building back the worn area, restoring to an acceptable thickness and applying an upgraded metallurgy to reduce future issues.

Finite Element Analysis

As part of our service we can conduct a Finite Element Analysis (FEA) to calculate the shell characteristics during welding demonstrating minimal deformation and integrity of the vessel.

Service scope

As a leading provider of specialized field services, we are global experts for plant retrofits and maintenance. Over 40 years of successful tower, drum and vessel experience assure our customers of a partner who is safe, cost-effective, and technically experienced. During your shutdown or turnaround we can mobilize our specialist teams for specific repairs and corrosion protection projects; alternately we can integrate the requirement within our wider scope of services including any internals maintenance, revamping or installation activates which need to be performed.

Global resources and capabilities

Regardless of your location, our global network is ideally placed, well equipped and experienced to service your needs. Mobilizing from our strategically placed facilities, we have the ability and proven track record to execute projects at any location around the world on a cost-competitive basis.