- Helicoaxial impeller designed for any Gas Volume Fraction from 0 to 100%

- Helicoaxial easily handles robust to solid particles (specific coating can be applied depending on the process)

- Standard bearing frame the OHH bearing range designed for long bearing life

- API 682 cartridge seal type, single or dual mechanical seals

- Bespoke seal plans depending on the application

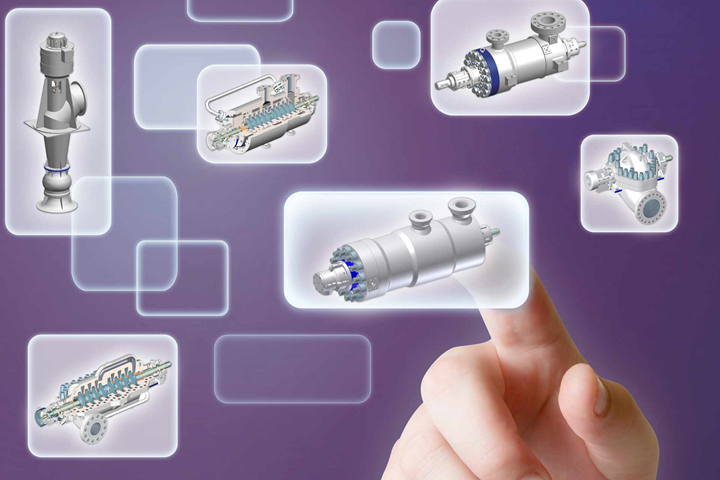

MPP-OHH single stage multiphase pump

Unique design for multiphase process applications

The MPP OHH is our API 610 (ISO 13709) type OH2 overhung, horizontal, centerline mounted, single stage, radially split pump combined with a helico-axial hydraulic. It is used as a circulation pump in HPI / Petrochemical applications where some free gas may be present in the process.

- Shell Omega process (Monoethylene Glycol process plant)

- Petrochemical processes near liquid-vapor saturation line

- Circulation pumps in fermentation process

- Circulation pumps for DAF waste water applications (Dissolved Air Filtration)

Main design features

- Helico axial impeller / diffuser specially designed for 2 phase flow application

- 7 different specific speeds available

- 3 different bearing frame size available

- 300# flange rating standard – 600# flange optional

- Heavy duty baseplate with 2 times ISO 13709 (API610) nozzle option

Key characteristics

Capacities |

Up to 1000 m3/h / 4400 US gpm |

Heads |

Up to 7 bar dp / 100 psi dp |

Pressures |

Up to 51 bar / 740 psi |

Power |

Up to 400 kW |

Maximum speed of rotation |

Up to 3600 rpm |