-

Vertical acid pump type Ensival Moret VASThe VAS pump range has been specifically designed for sulfuric acid pumping applications. Due to its engineered design, the VAS acid pump range minimizes the corrosion wear effect while offering high efficiency and reliability. Superior operational performance has been demonstrated with its longer maintenance-free operation from initial startup.

Vertical VAS pump allows for long lifetime and reduced maintenance in sulphuric acid plant

Long lifetime and reduced maintenance despite highly corrosive conditions

The challenge

The volute casing geometry generates radial thrust on the pump line shaft. The thrust leads to deflection and vibrations and causes wear of the pump bush bearing and the roller bearings. The highly corrosive conditions, where the clearance increases over time, further deteriorate the mechanical conditions of the pump. This effect is exponential, and as a consequence, the equipment lifetime is rapidly decreased.

The project

Sulfuric acid is one of the most important industrial chemicals. In the contact process, circulation pumps are required for the pumping of very corrosive high-temperature and high-concentration sulfuric acid in drying towers, absorption towers, and heat recovery systems. In most cases, vertical pumps are installed at the top of a tank to provide safe operation. In this case, the design featured a vertically mounted end suction pump with the volute casing installed on a suspension column with a separate discharge pipe.

The current trend in the industry is to increase the acid circulation flow. Sulzer’s vertical turbine pump is capable of handling the related thrust loads without damage to the pump.

Benoît Martin

Product Portfolio Manager at Sulzer

The solution

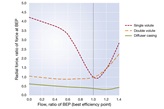

The vertically mounted pumps were replaced by Sulzer’s vertical turbine pump specially designed to handle sulfuric acid applications. The symmetric diffusor casing of the pump distributes the thrust equally. Detrimental thrust on the line shaft does not occur and as a result, the vibrations level and shaft deflection can be kept at a minimum. This advantage does not only apply to the best efficiency point of the pump, but to the entire flow range.

Customer benefit

- The lifetime of Sulzer’s vertical acid pumps is more than the double compared to the previous equipment at the customer’s site, and they have increased the MTBM (mean time between maintenance) remarkably.

- The symmetric construction ensures homogenous distribution of the flow stream and velocity in the discharge pipe. Consequently, local corrosion is avoided and monitoring of the pump conditions is easier.

- Differential thermal expansion does not occur thanks to discharge through a suspension column, without a discharge branch. The fact that there is only one acid/gas interface in the discharge column instead of four (two on the support column, one on the shaft and one on the discharge pipe) reduces corrosion significantly. These two factors are very important because stress corrosion and local temperature/concentration are two very damaging mechanical side effects.

The Sulzer difference

- The pump design extends the lifetime of the equipment and allows the customer to increase the mean time between maintenance (MTBM) remarkably.

- The compact design of Sulzer’s vertical turbine pump ensures easy installation and maintenance-friendly operation.

- The symmetric diffusor casing design allows the development of bigger pumps for higher sulfuric acid circulation flow.

Typical process conditions

| Liquid | Sulfuric acid |

| Concentration | 92% to 99.9% |

| Temperature | 60 to 150°C (200 to 250°C for heat recovery system) |

| Flow | up to 2.800 m3/h |

| Head | 20 to 30 m |