-

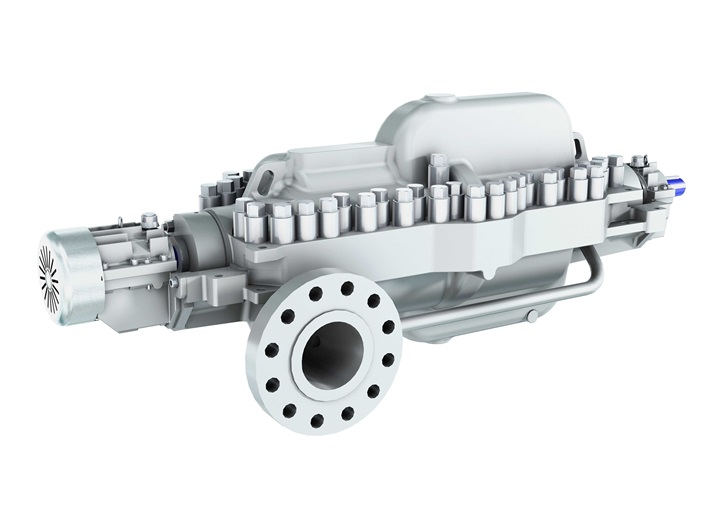

MSD axially split multistage pumpThe MSD pump has the broadest hydraulic coverage of any BB3 type multistage pump in the market. There are over 10 000 MSD pumps installed in product pipelines, boiler feed, water injection and even nuclear safety-related services around the globe.

-

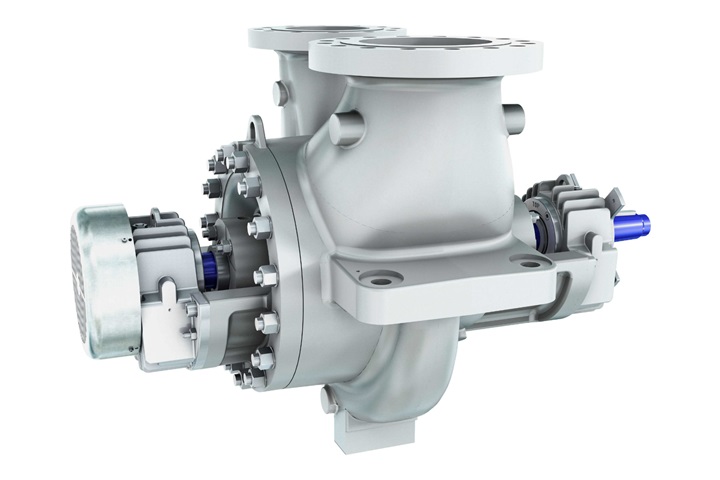

BBS and CD between bearings single stage pumpsThe BBS and CD models are API 610 (ISO 13709) type BB2, single stage, radially split pumps. They offer the widest range of hydraulic performance in the industry.

-

OHH overhung single stage pumpsThe OHH is our API 610 (ISO 13709) type OH2 overhung, horizontal, centerline mounted, single stage, radially split process pump.

-

CP horizontal radially split multistage barrel pumpCP ISO 13709 / API 610 Type BB5 radially split barrel casing pumps are used in both high-pressure oil production and high-temperature refinery applications.

-

GSG diffuser style barrel pumpThe GSG pump is the least costly form of ISO 13709 / API 610 Type BB5 high-pressure barrel pumps. The GSG back-to-back rotor stack is supplied on low- density services where rotor stability is critical.

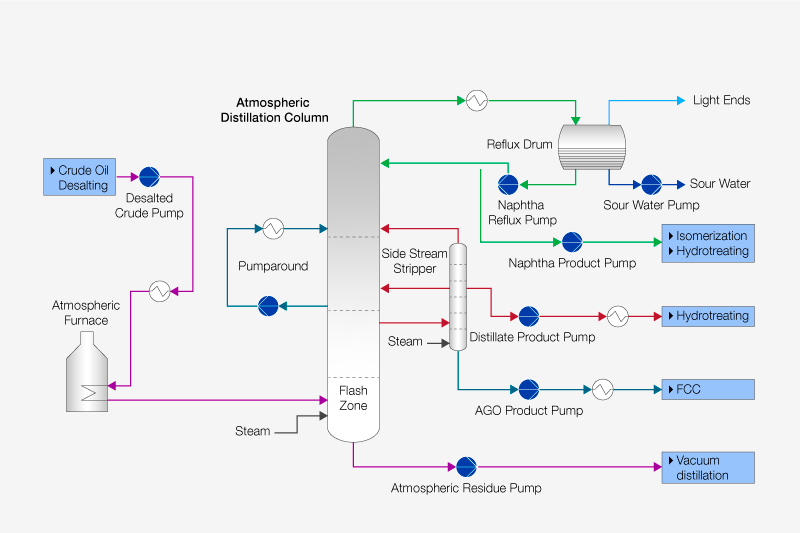

Crude Atmospheric Distillation

High performance equipment maximizes profitability

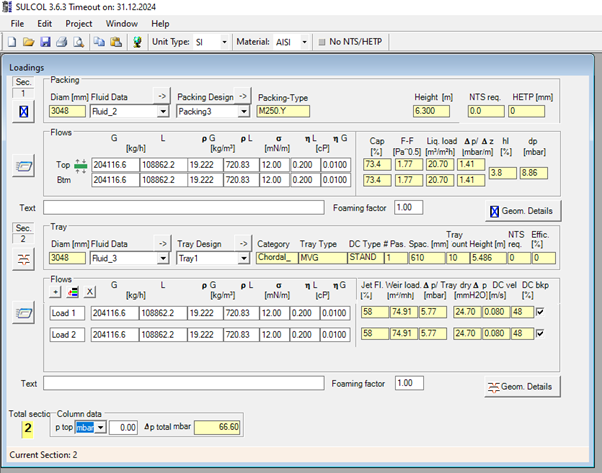

The atmospheric crude unit is where everything starts in a refinery so it must operate reliably and efficiently for years at time. Choosing the correct operating parameters and matching column internals is imperative.

Whether you have a grass roots or revamp application, our experienced engineers can provide you with the best possible, most cost-effective, and robust solution to meet your most demanding requirements.

Crude atmospheric distillation process

The atmospheric crude distillation unit begins with desalting of the crude and then continues through significant heat exchange train and fired heater prior to entering the main atmospheric column. In some cases, a preflash column precedes the main column. The main column itself is designed with several sections with side product draws to produce the various product streams such as light ends, naphtha, kerosene, diesel, gas oil, and the bottoms reduced crude stream. Many of the side streams are stripped with steam to help maintain product specifications. The main atmospheric column is one of the most complex columns within the refinery.

Since all refinery products begin in the crude unit, reliability is of the upmost importance. The tower needs to run free of shutdowns and maintenance for periods of 4-6 years. The column must therefore be robust from a mechanical and operational standpoint while also being able to accommodate different feeds to the unit.

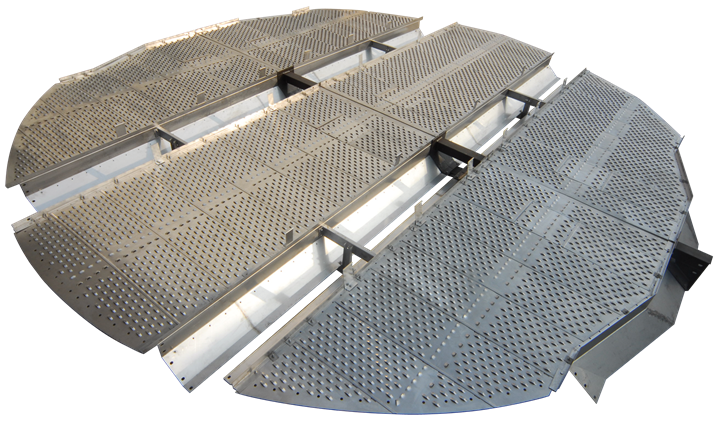

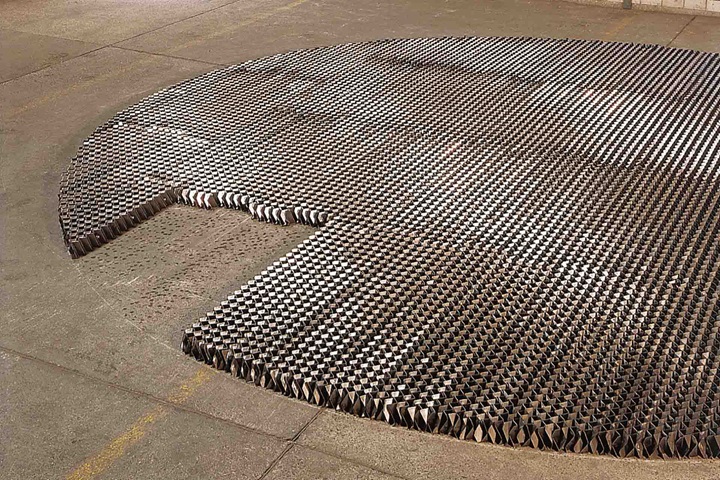

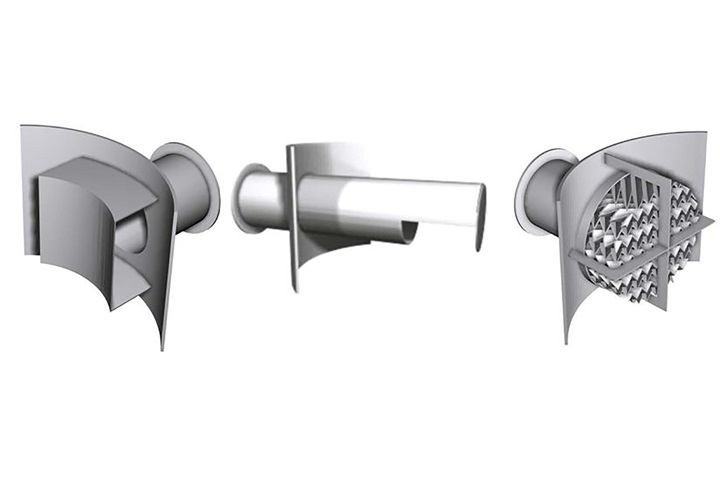

The main column is typically designed with high performance trays to allow for rate variations and resistance to fouling and corrosion over extended periods. Sulzer’s UFM Plus and UFM AF trays are often used to meet these needs.