- Replacing a locally made pump with a short lifetime (about three months)

- Getting a longer lifetime of the wetted parts (one year) at a reasonable price

- Finding the final solution after three trials

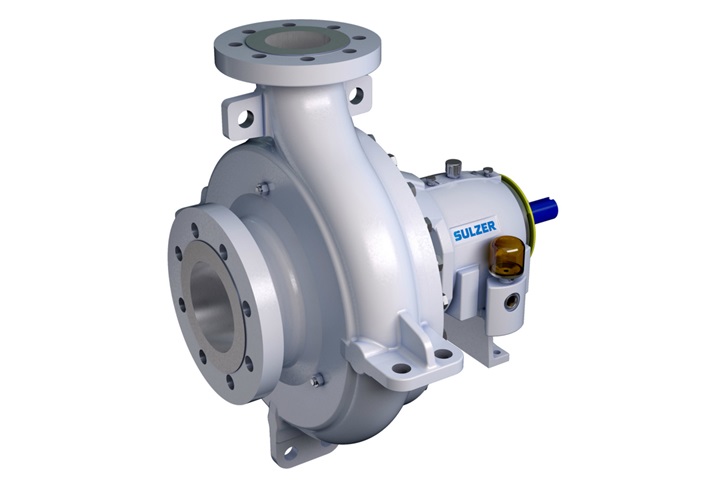

AHLSTAR WPP pump in fluorine salts production

Flexibility in design to meet customer requirements

Sulzer found the best possible combination of pump type and pump material to achieve an optimum solution between the price and lifetime of a pump for both corrosive and abrasive liquids.

- Fluorine salts production is a part of the phosphoric fertilizer process.

- The manufacturing process has two steps of absorption – an important part of the process.

- The pumped liquid is very difficult – it is both corrosive and abrasive. The temperature is high, too, and some cavitation is also present. The solids amount is high. The particles are fine, but they are very abrasive. The solids are partly SiO2.

- A combination of many factors is present.

The Sulzer difference

Sulzer Pumps is committed to supporting our customer’s competitiveness and profitability. We have a proven track record of design innovations creating reliable, safe and energy-efficient products. Combined with a professional approach, it brings positive results.

| Pump data | Process data | ||

|

AHLSTAR WPP44-150, open impeller, dynamic seal

|

Fluoric ammonium | ||

| Original ser. no | 100008720 | NH4F | up to 700 g/l |

| Later delivered ser. no | 100098624 | Temperature | 90 °C |

| Material | EH (4L HB300) | Solids | 450 g/l |

| Capacity | 90 l/s | Solids size | 20-40 mkm |

| Head | 45 m | Density | 1400 g/l |

- At first, Sulzer selected the AHLSTAR WPP wear resistant pump with open impeller in the 4U material and with the Dynamic Seal.

- The pump operated for about a year; after which it was worn out heavily with extensive abrasion discovered.

- After examining the affected surfaces of the wetted parts, it was decided to try the 4L material in order to get a lower cost of the pump. About the same lifetime was achieved.

- Finally the longest lifetime was achieved by using the EH (hardened 4L) material (300 HB hardness).

- The best possible combination of pump type and pump material was found after several trials.

- As a result, an optimum solution between the price and lifetime was found.

- More pumps were ordered for the same application.

Contact