Service excellence through innovation

Service fields: “The service business is becoming increasingly innovative”

In today’s service industry, what are customers looking for?

Daniel Bischofberger | The needs of customers in our industry do not differ much from what every one of us demands from a service supplier. When people buy a product, they want it to run when they need it to run, and they need the product to work the way it is supposed to work. And the costs should be as low as possible. Customers are looking for service providers who possess the tools, equipment, and expertise to make sure that their machine is running reliably and efficiently at optimized costs.

How does Sulzer differentiate itself from other competitors?

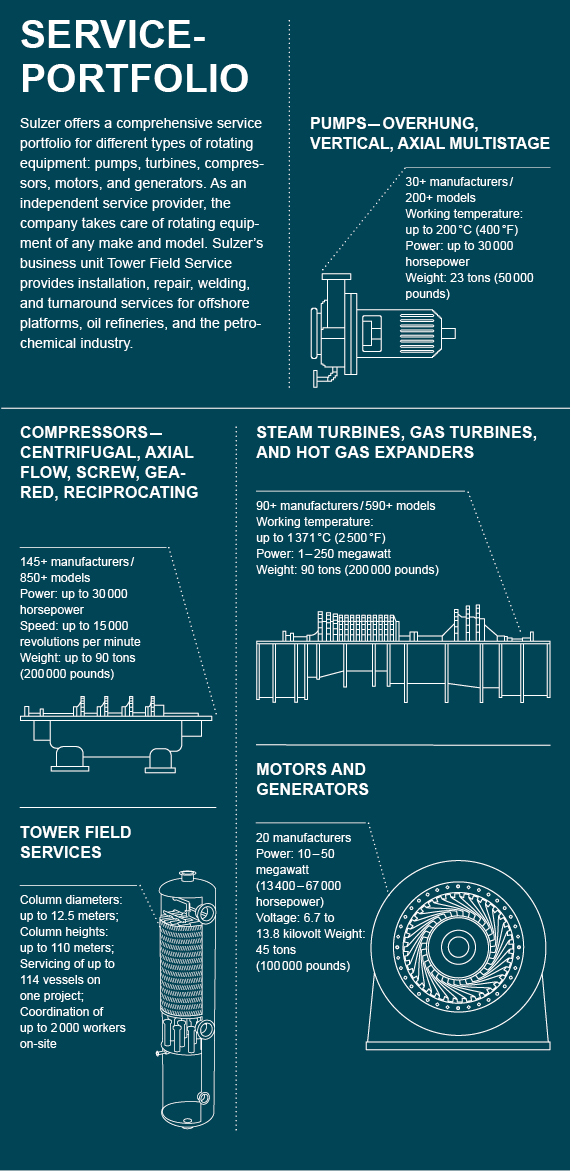

DB | Sulzer combines the best of two worlds: The company has the technical expertise of an original equipment manufacturer (OEM) and the competencies of an independent service provider (ISP). We are flexible and fast. With our network of roughly 100 service centers in 25 countries, we are close to our customers. In addition, our product and service portfolio is exceptionally broad.

“We combine the best of two worlds: the world of the original equipment manufacturer and the world of the independent service provider.”

Daniel Bischofberger

Division President Rotating Equipment Services

Can you give an example?

DB | One of our customers relocated the gas and steam turbines of two different plants to a new combined-cycle power plant at a different site. However, the performance of the steam turbines was not compatible with that of the gas turbine. Hence, the steam turbines had to be rerated, which means that the performance had to be adjusted. This requires know-how you would normally expect from an OEM but not from an ISP. Thanks to the competence of our team in Houston, we completed the job to the customer’s fullest satisfaction. This example shows that we are able to provide services for a broad range of products, and we have the technical expertise to do more for our customers than they normally expect from an ISP.

Sulzer has consolidated its service business. What does that mean?

DB | We are becoming a one-stop service supplier. We are establishing service centers where we can repair a range of different products under one roof. That way, operators have one access point for the service of all their rotating equipment. Now that the service and new equipment businesses are in different divisions, we have to ensure that the close collaboration and knowledge exchange remain as strong as they were when they were both in the same division. For example, the pumps service teams need to share their field experience from our installed pumps base with our colleagues in product development to further optimize our pump designs.

What trends do you see in the service industry?

DB | New players are entering the market, which results in growing competition but also in growing innovation. On the customer side, we see that operators are increasingly optimizing their maintenance and operation costs. This does not necessarily mean “the same but cheaper.” It also includes services enabled by digitalization, such as monitoring and maintaining equipment proactively, prolonging maintenance intervals, reducing revision time, and developing innovative repair technology to extend the lifetime of products and components. Because some customers are streamlining their organizations, they expect their service partner to take over activities they cannot perform in house anymore.

Based on your extensive experience, where do you see Sulzer’s potential?

DB | We have a strong regional footprint, but we can improve in our exchange of skills and knowledge among these regions. We have to leverage the best practices of a global company and copy from each other with pride. We are working on a global growth strategy for our service ranges — turbo services, pumps services, and electromechanical services. Further, in order to be even closer to our customers, we plan to establish more multipurpose service centers where we provide a variety of different services under one roof. We still have some work to do when it comes to collecting data from our installed pumps base more systematically, reducing the leadtime of pumps spares, and better integrating the motors and generators business. Regionally speaking, I see growth potential for our service business in Asia.

Which skills do you expect from a service employee?

DB | Service is a people business. A professional service team is essential for us. There are three skill sets that I — and our customers — expect from a service employee. First: customer focus and entrepreneurship. You have to be able to listen to customers, to ask the right questions, and to find the right solution with them. Second: flexibility. As a service supplier, you need to be available around the clock, and you need to be fast, reliable, hands-on, and pragmatic. Third: technical competence and practical experience. Because every product behaves differently in the field, theoretical knowledge is required but usually not sufficient.

Are there women in the service business?

DB | Far too few [laughs]. Unfortunately, the industrial service business — we are active in markets such as oil and gas, power, or mining — attracts fewer women than other markets. In addition, many of our employees work on the shop floor as mechanics and on customers’ sites as field service engineers. These kinds of jobs traditionally have a lower share of women. Fortunately, there are many women in functions like sales, HR, finance, or engineering at Sulzer. Despite the difficulties in attracting more women, I truly believe in the power of diversity. We continue to strive for a higher share of women in our businesses, be it in white- or blue-collar functions.