Related links

-

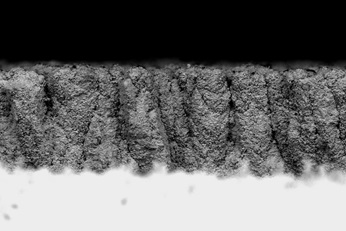

DC Coalescers™Our DC Coalescer™ technology provides significantly lower settling times for primary dispersions with droplets as small as 30 microns.

The demands on materials in modern machine construction are constantly rising. The following examples show how Sulzer meets this challenge and how the clients benefit from high-tech materials.

Pumping corrosive fluids containing abrasive solids is a challenge. Sulzer can adapt pumps to such requirements by making the ideal choice of hydraulics and seals and by improving the materials used to produce the pump.

Sulzer improves the performance of extraction columns by using coalescers made of composite materials, and thereby extends the range of application for these columns. Customer projects confirm the process and cost advantages of the DC coalescer™.