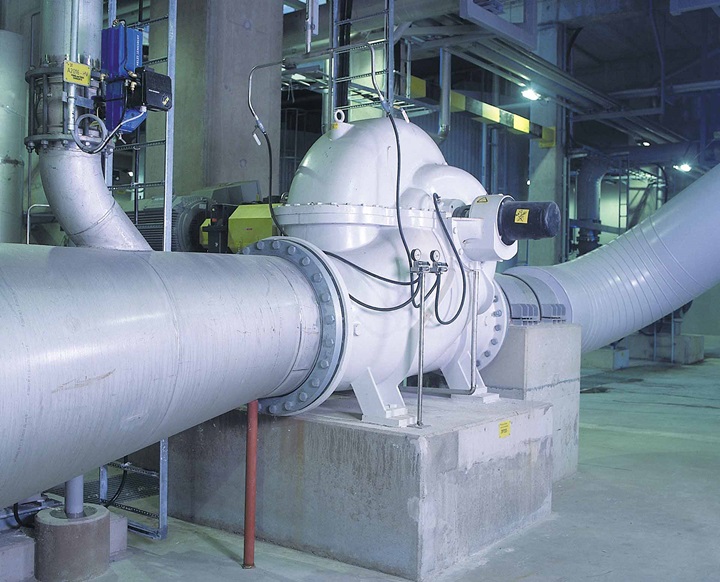

- Excellent performance in all industrial segments

- High-efficiency propeller with large axial thrust

- Suitable for the most demanding industrial applications

- Low total cost of ownership through smart design and energy efficient propeller

- Quick and easy installation, safe operation, easy maintenance and service

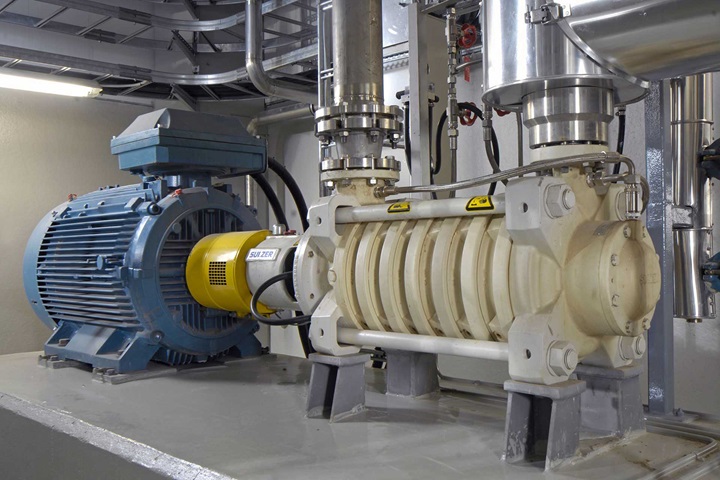

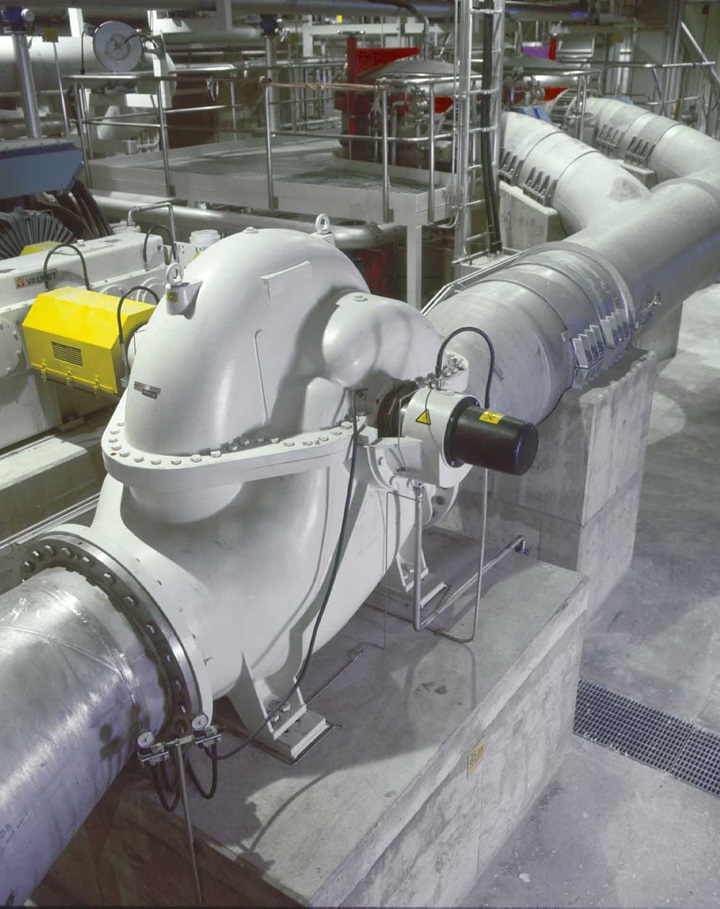

SALOMIX™ SLR/STR side-mounted agitators

Mix and match – efficient mixing technology

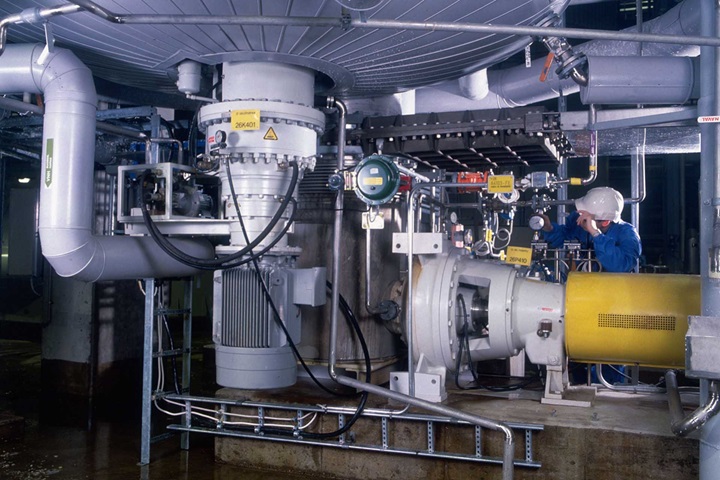

SALOMIX™ SLR/STR side-mounted horizontal agitator is a multi-purpose agitator. It consists of high efficiency propeller, solid stainless steel shaft, reliable mechanical seal, robust gear reducer, elastic coupling and self-aligning flange mounted motor, all in an extremely compact construction.

- Clean and slightly contaminated liquids

- Viscous liquids

- Fibrous and other slurries

Main design features

- High-efficiency propeller

- Reliable mechanical seals

- Reliable gear drive unit designed for tough applications

- Low spare part costs due to high standardization

Key characteristics

| Propeller diameters | 315 - 800 mm / 12.4 – 31.5 in |

| Power | 2.2 - 11 kW / 3 - 15 hp |

| Maximum speed of rotation | Up to 470 rpm |

| Performance range | SALOMIX SLR/STR agitators have a wide and comprehensive hydraulic coverage which enables their use in all mixing applications. |

| Stock concentration | Up to 6 % |

Documents

Brochures

-

SALOMIX™ SLH side-mounted agitatorpdfLanguages:

-

SALOMIX™ side-mounted agitatorspdfLanguages:

-

SALOMIX and Scaba top-mounted agitatorspdfLanguages:

Case studies

-

SALOMIX™ SSA reduces power consumption in pulp mill fiber recoveryEnergy savings are high on the daily agenda. The mill was, therefore, keen to install the world’s first SALOMIX SSA agitator and to cut the energy bill, without compromising the process up-time.

-

Trusted partner for new wood-based processesSulzer is a company with long and solid experience and proven expertise in several important customer segments. Pulp, board and paper processes and applications as well as new ones based on wood raw materials represent high-priority commitment and partnership areas for the business and product development organization. Read the whole article.

-

How to optimize agitatorsSulfuric acid is the key chemical used in the production process of wet phosphoric acid (WPA). Hence, the production of sulfuric acid close to the phosphoric acid plant (PAP) has many advantages. Not only does this reduce transport costs, but the nearby production of sulfuric acid, which is an exothermal process, allows the residual thermal energy to be used for the manufacture of concentrated phosphoric acid. Steam is generated to feed the heat exchanger located within the concentration unit of the phosphoric plant. Read the whole article.

-

Supporting sustainable fuel productionSulzer is at the forefront of engineering excellence and quality, delivering best-in-class solutions to support companies in important growth industries, such as biobased, renewable energy production. Understanding precisely what customers need, as well as maintaining the highest standards in manufacturing and service has led to many significant project wins, not least the collaboration with Inpasa, Latin America’s largest producer of corn ethanol. By the end of 2022, this partnership is anticipated to have grown to the delivery of almost 1’000 pieces of equipment, including pumps, sealing systems, agitators and static mixers across three production plants in Brazil. Read the whole article.

-

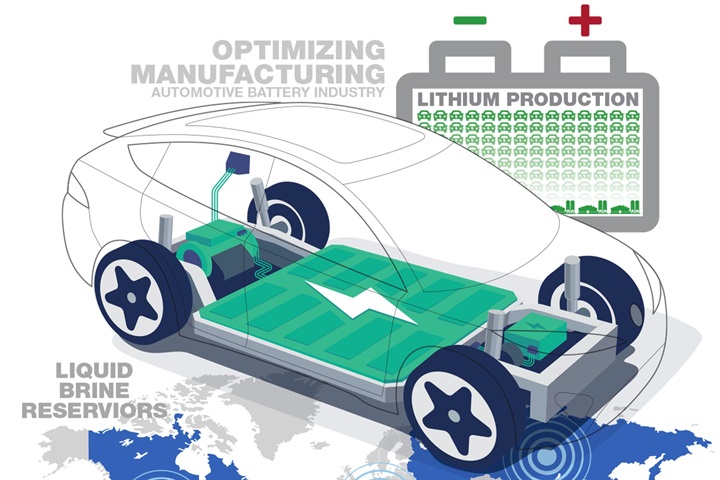

Driving up efficiencyThe adoption of electric vehicles across the world is increasing rapidly and this demand needs to be matched by the supply of batteries. As new processing plants and manufacturing facilities are constructed, it is important that they employ the latest in pumping technology to ensure optimum reliability and efficiency. Read the article.

-

Case studiesWherever fluids are pumped, mixed, controlled or applied, we are there. See how our solutions create value for customers and learn how we can make your pumping and mixing processes more efficient and profitable, safeguarding your production and ensuring lasting reliability.

Industries

-

Pulp, paper and boardSulzer is the world leader in innovative, reliable, and proven pumping, agitation and mixing solutions for the pulp and paper industry. Our deep process and application knowledge is based on long-term close co-operation with the producers, machinery suppliers and engineering companies.

-

Chemical pulp fiber lineProven pumping, mixing and agitation solutions for your cooking, washing, screening, oxygen delignification, bleaching, and storage processes to ensure process reliability, high efficiency, and low operating costs.

-

Chemical recoverySulzer’s extensive product portfolio is designed to meet the most demanding hydraulic coverage requirements in your evaporation, recovery boiler, and white liquor preparation processes.

-

Industrial water and effluent treatmentSulzer has a deep knowledge in wastewater treatment, and with our wide product portfolio we can now offer energy-efficient and reliable solutions for your water collection, neutralization, flocculation, sedimentation, cooling, aeration, sludge storage, digestion, and dewatering processes.

-

Mechanical pulp lineSulzer’s ideal product portfolio for challenging pumping, agitation, and mixing operations in refining, grinding, CTMP, screening, reject handling, and bleaching processes.

-

Paper and board machine and systemsSulzer’s extensive product portfolio is designed to meet the most demanding hydraulic coverage requirements and for all types of liquids, making it ideal for challenging pumping, agitation, and mixing operations in stock preparation, PM approach system, broke system, white water system, vacuum system, condensate system, and shower water system processes.

-

Power plantsSulzer’s extensive product portfolio to maximize the performance and reliability of your solid organic fuel biomass power plant, solid industrial or municipal waste fuel biomass power plant, and liquid or gaseous organic fuel biomass power plant processes.

-

Pulp drying machineIncreased hydraulic excellence for your approach, cleaning, drying machine, vacuum, broke, and white water system processes.

-

Recycled fiber lineEnergy-efficient products with low life cycle costs and a lighter environmental footprint for your pulping, screening & cleaning, flotation, washing, and bleaching processes.

-

Sugar, starch and sweetenersEfficient production of sugar, starch and sweeteners puts high demands on the processing equipment. Thanks to many years of experience and comprehensive process know-how, Sulzer offers a wide portfolio of innovative process pumps, special pumps, mixers, agitators, compressors and aerators for these industry sectors.

-

Mining and metalsLong experience and detailed knowledge of metals and mining applications with different raw materials makes Sulzer a reliable pump supplier for these industries.

-

Oil gas and chemicalsHigh-performance pumps from Sulzer provide cutting edge solutions for the production, processing and transportation of hydrocarbons and CO2. Our technologies enable efficient separation processes for liquids and gas. We provide reliable services for compressors, turbines, motors, and generators through our global aftermarket network.

-

FertilizersOur pumps, mixers and agitators provide durability and reliability for fertilizers production as well as for corrosive and abrasive liquids and high gas content. Our specific industry experience also includes separation processes and servicing of pumps, compressors, turbines, and motors.

-

BiofuelsBiofuels from renewable sources show great potential as sustainable transportation fuel. Based on our experience in demanding processes, we work with customers to develop advanced pumping, mixing, and distillation solutions for the production of biofuels, from pilot to commercial-scale installations.

-

Industrial water treatmentWe provide extensive coverage of energy-efficient and reliable pumping, mixing, and aeration solutions for all industrial water treatment processes.

-

Municipal wastewaterSulzer plays a major role in returning clean water to its source, by providing effective solutions for wastewater collection and treatment focused on safety, reliability, and efficiency. Sulzer offers the most up-to-date range of pumps, submersible mixers and agitators, aeration systems, high speed compressors and equipment controllers, supported by a world wide service organization.

Related links

Products and services

-

EX3 propeller for SALOMIX™ agitatorsSulzer's new high-efficiency EX3 propeller exceeds the current SALOMIX™ MX4 propeller in both efficiency and thrust. With a smart retrofit system, the EX3 propeller can replace MX4 propellers on SALOMIX™ side-entry agitators.

-

SALOMIX™ SSA side-mounted agitatorsA robust, belt-driven agitator for light to heavy duties. Agitator performance can be adjusted through other drive combinations. Features the new high-efficiency EX3 propeller.

-

SALOMIX™ SSF side-mounted agitatorsA gear-driven agitator for light to heavy duties. Cone design with in-tank bearing makes it able to handle high radial forces and heavy-duty operations. Features the new high-efficiency EX3 propeller.

-

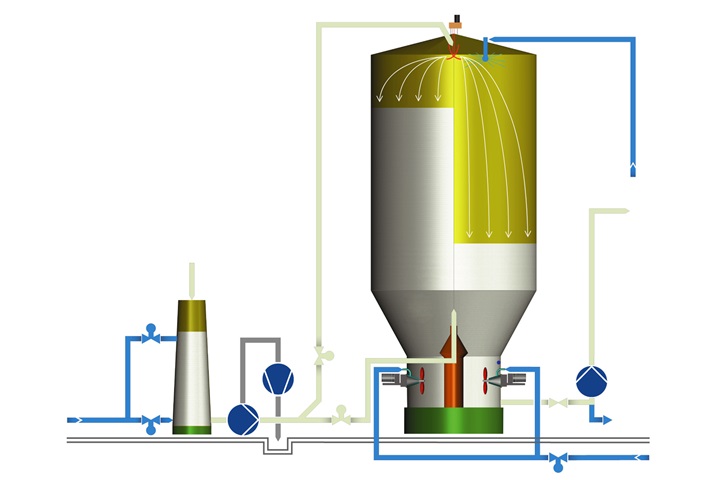

Tower management systemsSALOMIX tower management technology offers a wide range of systems for industrial tower applications. SALOMIX TES, SALOMIX GLI and SALOMIX VULCA systems help manage the demanding tower processes.

Talk or write to our experts to find your best solution.