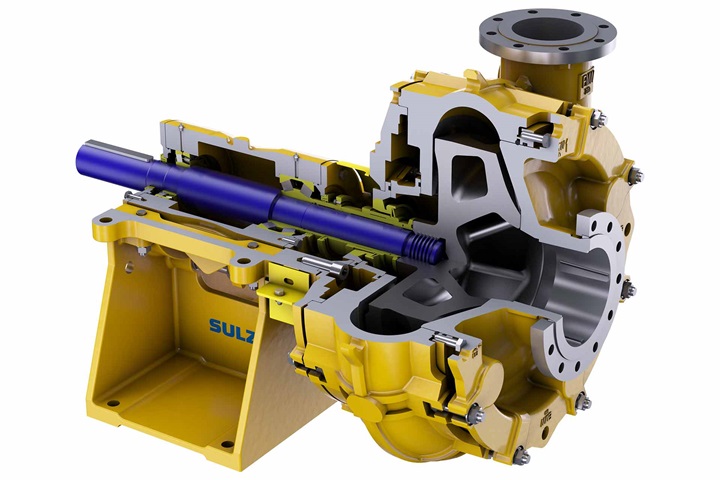

- Heavy-duty construction

- Specifically designed for molten sulfur applications

- High-quality materials, highly reliable and efficient design ensure longer mean time between maintenance and minimized total cost of ownership

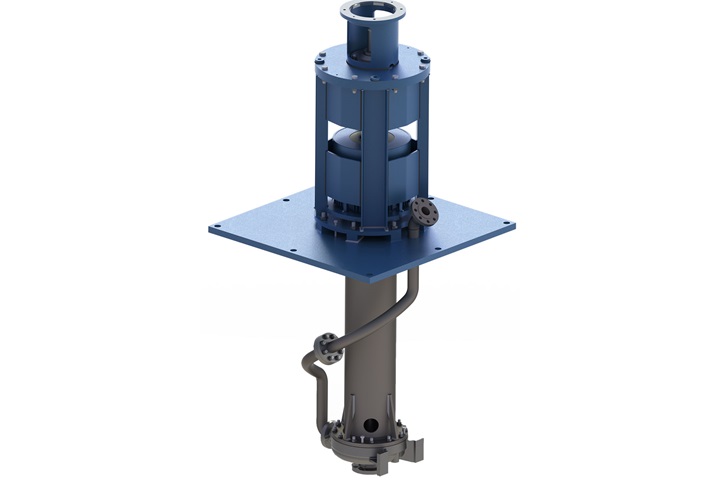

Cantilever sump pump type Ensival Moret VSF

Designed for molten sulfur applications

The VSF vertical pump range has been specifically designed to handle molten sulfur applications. Its engineered design ensures high corrosion resistant and longer service lifetime.

The VSF pump range is perfectly suitable for the following applications:

- clean or dirty molten sulfur

- constant temperature applications in various industries

Main design features

- Open or vortex impellers

- No sealing required

- No intermediate bearing

- Steam jacket column and discharge pipe to maintain optimal required temperature

- Extended length design available

- Reliable worldwide proven design

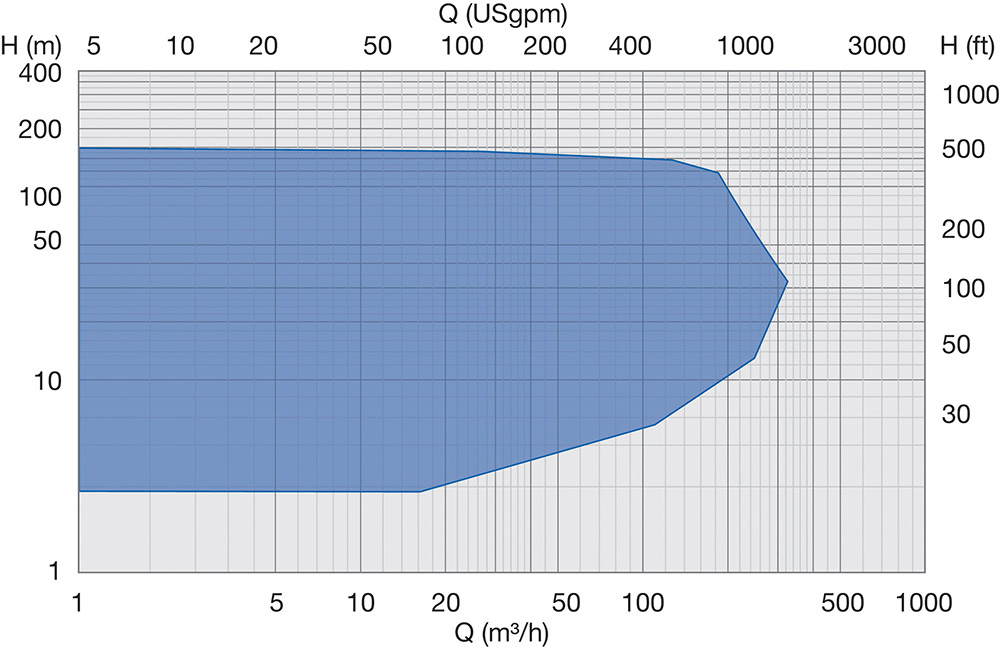

Key characteristics

| Capacities | up to 300 m3/h / 1’300 USgpm |

| Heads | 160 m / 500 ft. |

| Pressures | up to 20 bar / 290 psi |

| Temperatures | up to 180°C / 350°F |

| Higher capacities and heads available upon request. |