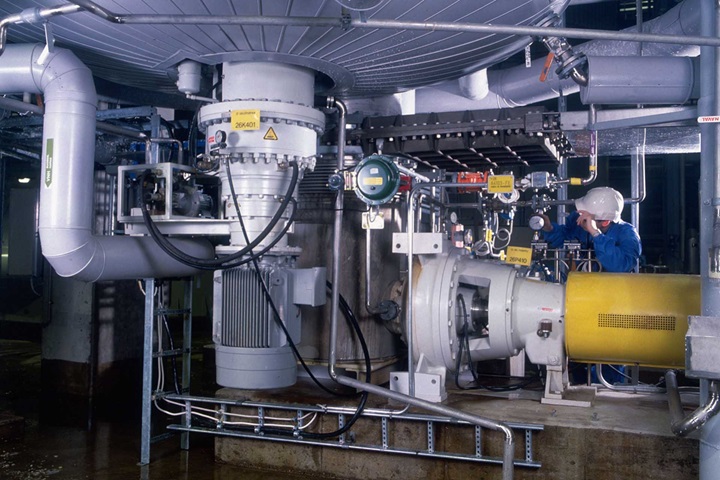

- Long and trusted experience in the pulp, paper and board and other industrial segments

- A single model can be used for the entire wide operating range of an MC pump

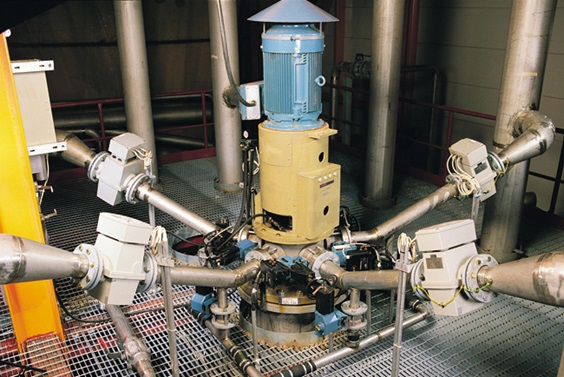

- Easy operational connection to the other process equipment

- Unique heavy-duty design

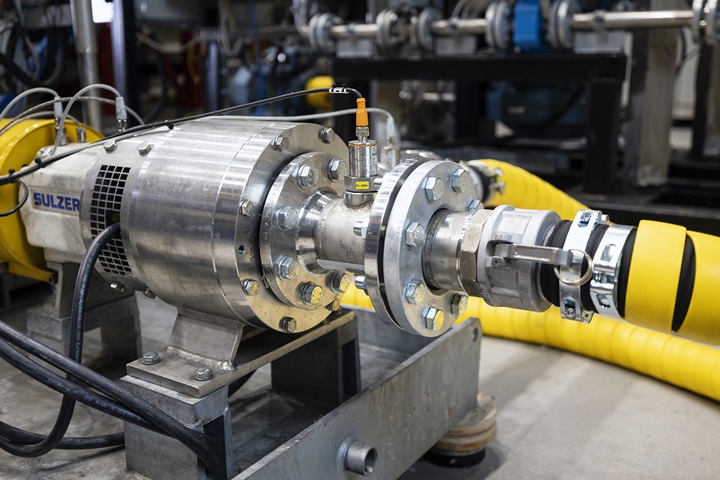

- Quick and easy installation in a pipeline, reactor feed and reactor discharge

- Reliable operation, easy maintenance and service

- Low energy consumption