-

Ejector for pumpSulzer ejector is suitable for all horizontally installed pumps. It offers an easy solution for enabling fast, reliable and fully automated priming for retrofitting existing or new installations. It also includes a full automation package.

-

AHLSTAR NPP/T non-clogging process pump rangeAHLSTAR NPP/T non-clogging end-suction single-stage centrifugal process pumps are designed for industrial large solids containing liquid or abrasive slurry applications to avoid plugging. The pump exceeds the requirements of ISO 5199.

CASE STUDY

AHLSTAR™ with Sulzer Ejector improves sump pumping in a cardboard mill

The challenge

This European mill produces 240’000 tons of cardboard from wastepaper per year. The cardboard is used to make plasterboard and for packaging. Various effluents from the mill are collected in different steps of the process and then treated in a modern, integrated wastewater treatment plant.

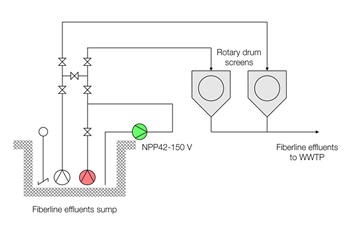

The main effluents from the fiber line process are collected in a large, 2.5 m deep sump prior to being pumped further through rotary drum screens and sent to the wastewater treatment plant. The liquids in the sump have varying characteristics and can be highly polluted with all kinds of solid particles (fibers, clips, tapes, ropes, etc.).

The initially installed sump pumps failed frequently. The two non-Sulzer submersible pumps were regularly clogged, disturbing the whole process and generating high repair costs. The customer decided to look for a more reliable pumping system and asked Sulzer for help.

The solution

After thorough discussions, the client and Sulzer agreed on a radical alternative: one dry-installed process pump with a complete priming system. An AHLSTAR NPP42-150 non-clogging pump unit with ejector soon replaced the failing submersible pumps. The installation was fast and easy, and only minor piping modifications were needed.

The NPP42-150 pump unit is located above the liquid level in the sump. At each pump start, a fully automated priming is done in a few seconds with the Sulzer Ejector package. The NPP42-150 pump has been running smoothly for more than two years now, without any blockage. One of the initial submersible pumps was removed from the sump and the other one is kept as standby, only being used from time to time in parallel with the NPP42-150, when a maximum drainage flow is required.

Customer benefit

The AHLSTAR non-clogging NPP42-150 with vortex impeller is the right pump for sump applications where liquids are heavily polluted with debris and other big solid particles.

The previously installed submersible pumps were of cast iron, whereas all the wetted parts of the NPP42-150 pump are of duplex stainless steel. This material is ideal for liquids which can be both corrosive and abrasive. It ensures a much longer pump service life with minimum wear of parts.

The NPP42-150 pump unit is above the sump liquid level, and this makes all maintenance operations rapid and safe.Several other AHLSTAR process pumps are installed in the cardboard mill. The inventory control of spares is therefore easy.

The Sulzer Ejector is an inexpensive and simple device powered by compressed air from the mill network. It allows full priming of the inlet pipe and pump in a few seconds. After priming, the ejector is stopped, and the NPP42-150 pump starts running. No compressed air is required during normal pumping operation.

The Sulzer Ejector was delivered with an automation package that makes the whole priming operation extremely simple

AHLSTAR non-clogging pump unit for wastewater sump (pit depth 2.5 m)

| Pump type | AHLSTAR NPP42-150 V |

| Flow | 350 m³/h |

| Head | 20 m |

| Speed | 1’000 rpm |

| Motor power | 55 kW |

| Impeller | Vortex – 340 mm |

| Max. solids passage | 80 mm |

| NPSHr | 5 mcL |

Complete Sulzer Ejector package including:

- Ejector

- Valves with actuators for motive air and ejection suction pipe

- Level control switch

- Control box with logic