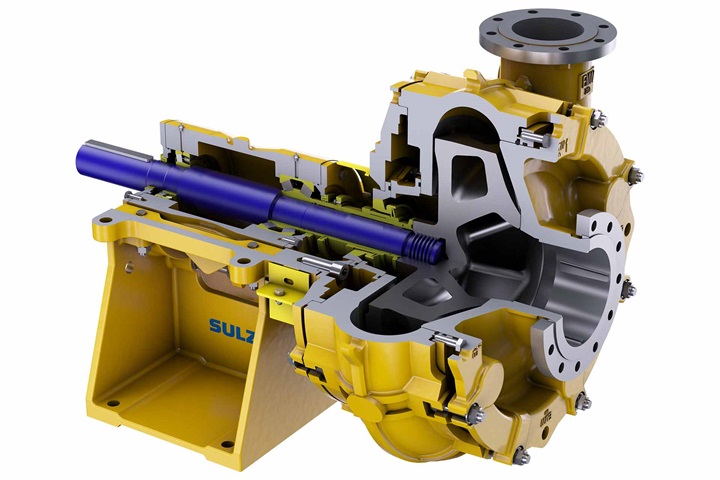

- High corrosion resistance due to compact and unique design

- Wide range of highly corrosion-resistant materials guarantees high durability of the pump

- Reliable design ensures longer maintenance-free operation

- Easy assembly and maintenance of the pump

- Low plant down time due to high reliability

Vertical sulfuric acid pump type Ensival Moret VAS

Corrosion minimized by design

The VAS pump range has been specifically designed for sulfuric acid pumping applications. Due to its engineered design, the VAS acid pump range minimizes the corrosion wear effect while offering high efficiency and reliability. Superior operational performance has been demonstrated with its longer maintenance-free operation from initial startup.

The VAS acid pump range has been designed to meet the requirements in H2SO4 plants such as

- Absorption tower

- Drying tower

- Heat recovery system

Main design features

- Symmetrical diffuser casing design minimizes radial loads and shaft deflection ensuring longer pump service life

- Auxiliary packing rings to prevent acid vapors and minimize corrosion

- Non-contacting shaft sealing with throttle bushing which reduces head pressure and minimizes leakage overflow

- Easy assembly and installation of the pump to the tank due to symmetric design with circumferential mounting plate

- Fully protected bolts against corrosion allow easy assembling and dismantling of the pump

- High efficiency and low net positive suction head (NPSH) due to closed impeller

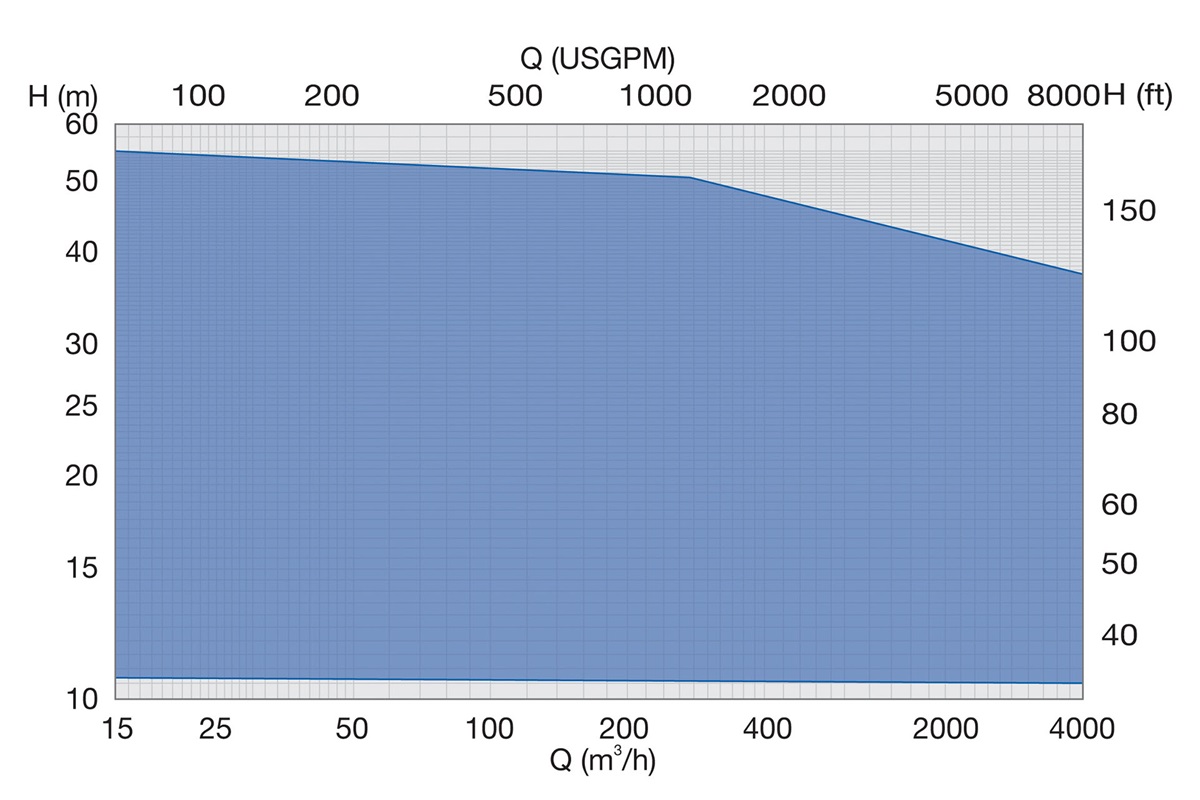

Key characteristics

| Capacities | Capacity up to 4,000 m3/h / 17,500 USgpm |

| Heads | Heads up to 45 m / 148 ft |

| Pressures | Pressure up to 20 bar / 290 psi |

| Temperatures | Temperature up to 150°C / 291°F Temperature up to 250°C / 480°F (heat recovery) |

| Maximum speed of rotation | Speed of rotation up to 1,800 rpm |