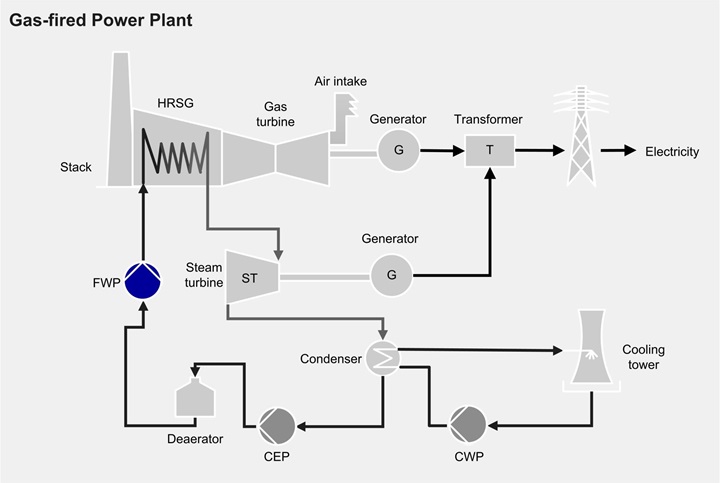

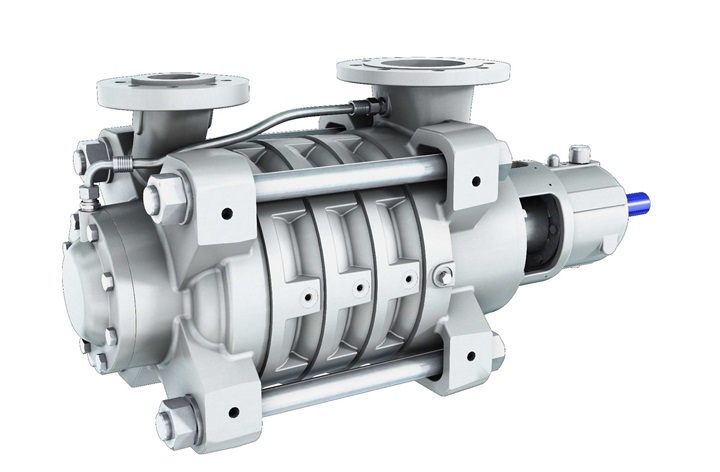

- Modular hydraulics for high efficiency in a wide range of operating conditions as required for gas-fired combined-cycle power plants

- Optimized design for thermal conditions as applicable in gas-fired combined-cycle power plants

- Large branch sizes for optimized inlet flow, low noise level and higher allowable forces and moments

- Unaffected by rapid temperature variations and therefore highly suitable for gas-fired combined-cycle power plants where frequent start-stop operation is specified

- Easy access to the seal cooling chambers for cleaning

- Stiff shaft design for critical speeds above the maximum operating speed

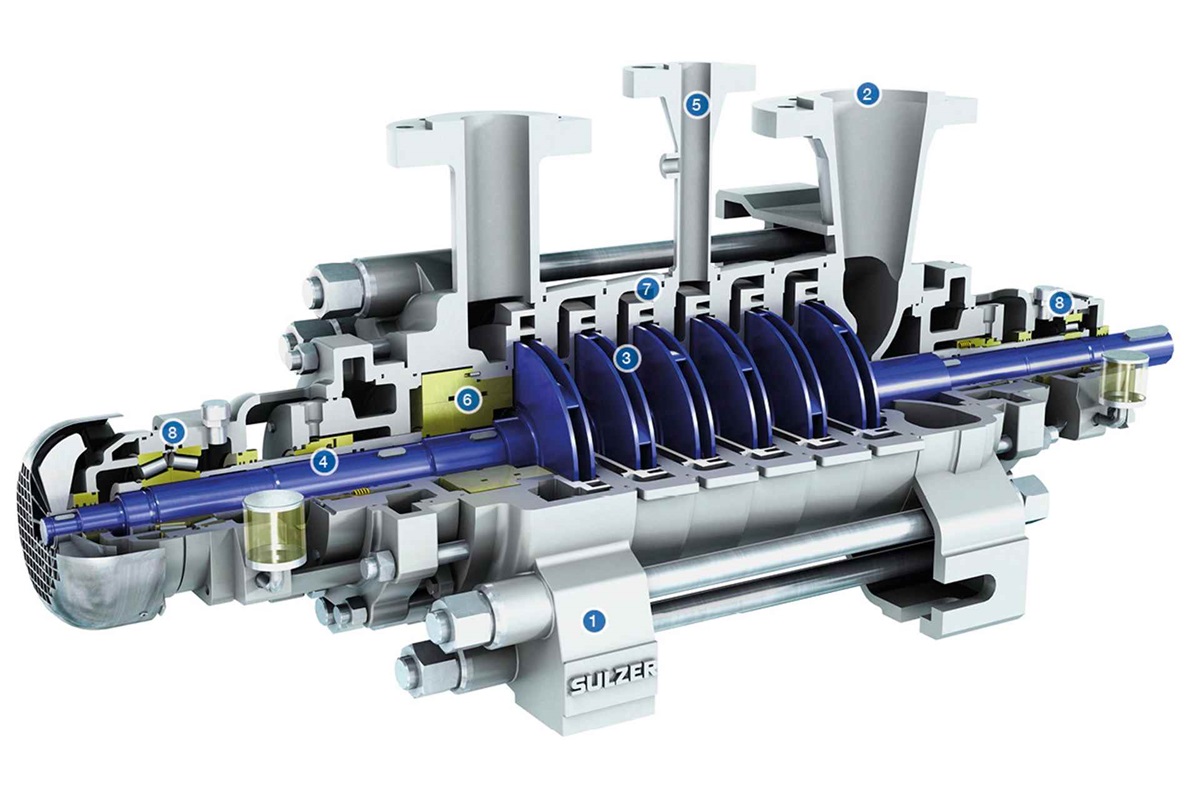

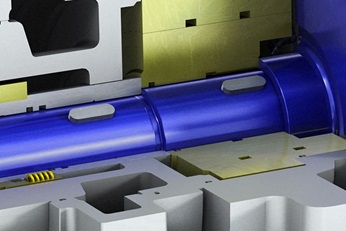

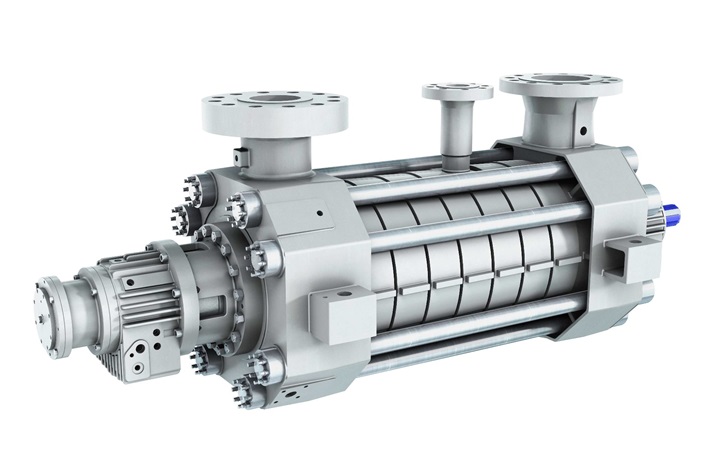

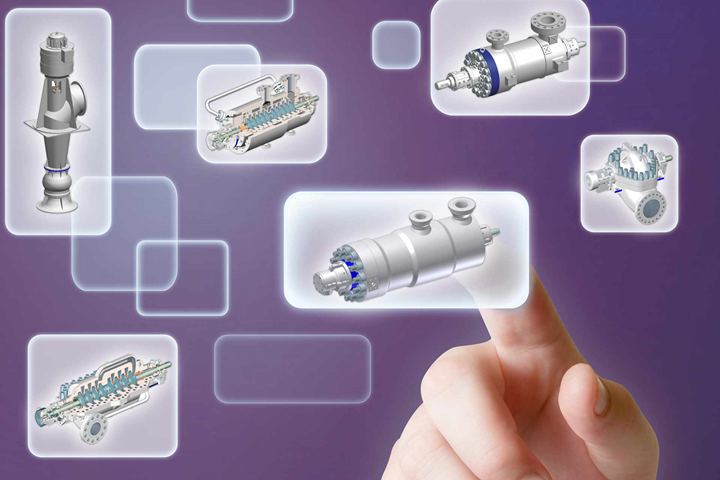

MC high-pressure stage casing pump

High-pressure pump designed to your spec

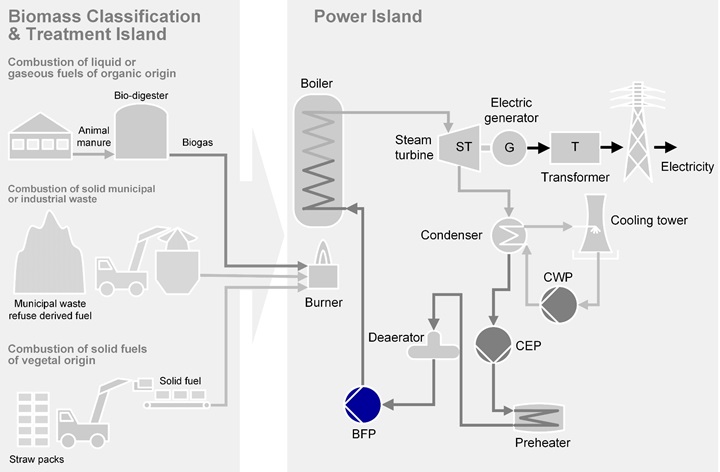

The MC pump is primarily designed for power applications, such as: auxiliary boiler feed services; Nitrogen Oxides (NOx) abatement and fuel injection in combined-cycle power plants; boiler feed for biomass fired and industrial power plant; and steam generator feed in concentrated solar power plants. The design is ideal for:

- Main and auxiliary boiler feedwater pump duties up to 180°C

- Nitrogen Oxides (NOx) abatement and fuel injection in gas-fired combined-cycle power plants

- Condensate extraction pumps in power stations and industrial plants

- Auxiliary services within gas-fired combined-cycle and industrial power plants

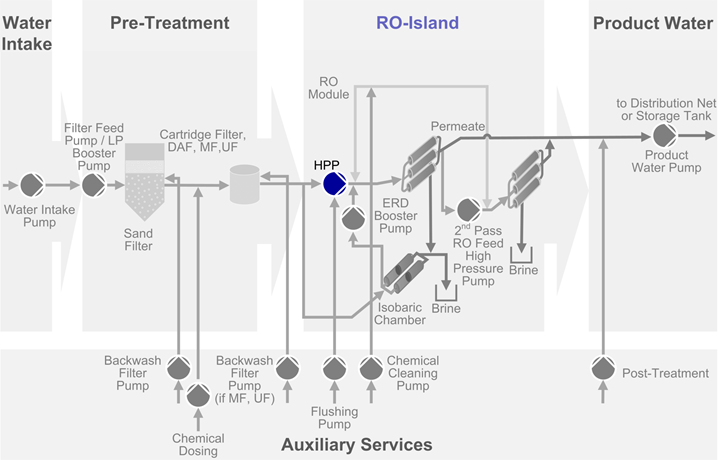

- Feedwater pump in desalination by reverse osmosis

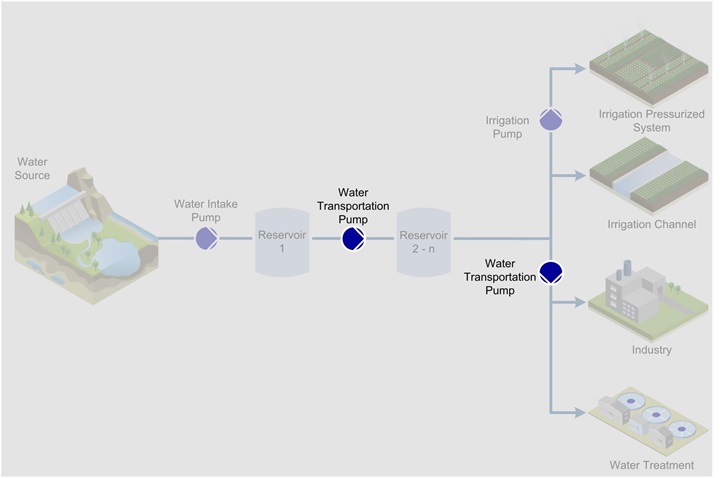

- High pressure water in general industry

- Feedwater pump for gas-fired combined-cycle power plants

- Feedwater pump for concentrated solar power plants

- Boiler feedwater pump for biomass and industry power plants

1. Casing support

Foot or shaft centerline mounted for large sizes and high temperatures

2. Branches

- Large suction branches optimize inlet flow

- Reduce noise levels through low branch velocities

- Allow higher forces and moments

3. Impellers

- Several hydraulic sets per pump size guarantee high efficiencies and low operating costs over a wide operating range

- Low net positive suction head required (NPSHR) first stage; double suction first stage can be provided for selected sizes

4. Shaft

Stiff design resulting in higher critical speed than running speed and small shaft deflection. Areas subject to wear are protected

5. Intermediate take-off

Up to two bleed-off nozzle are possible

6. Hydraulic thrust balancing system

Axial thrust can be balanced by balance drum with thrust bearing or by balance disc without thrust bearing

7. O-rings

Casing sealing by confined O-rings, therefore unaffected by rapid temperature variations and high pressures

8. Multiple bearing types

Antifriction bearings for low cost and hydrodynamic bearings for higher energy services

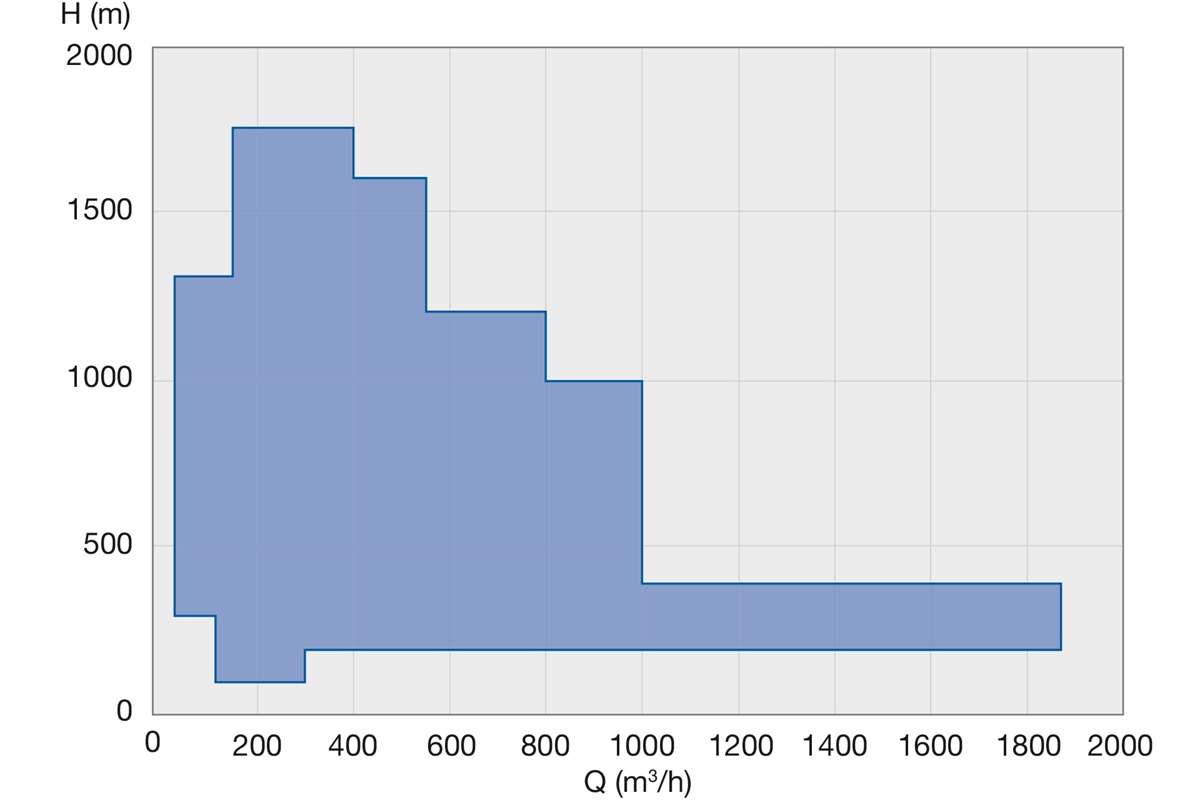

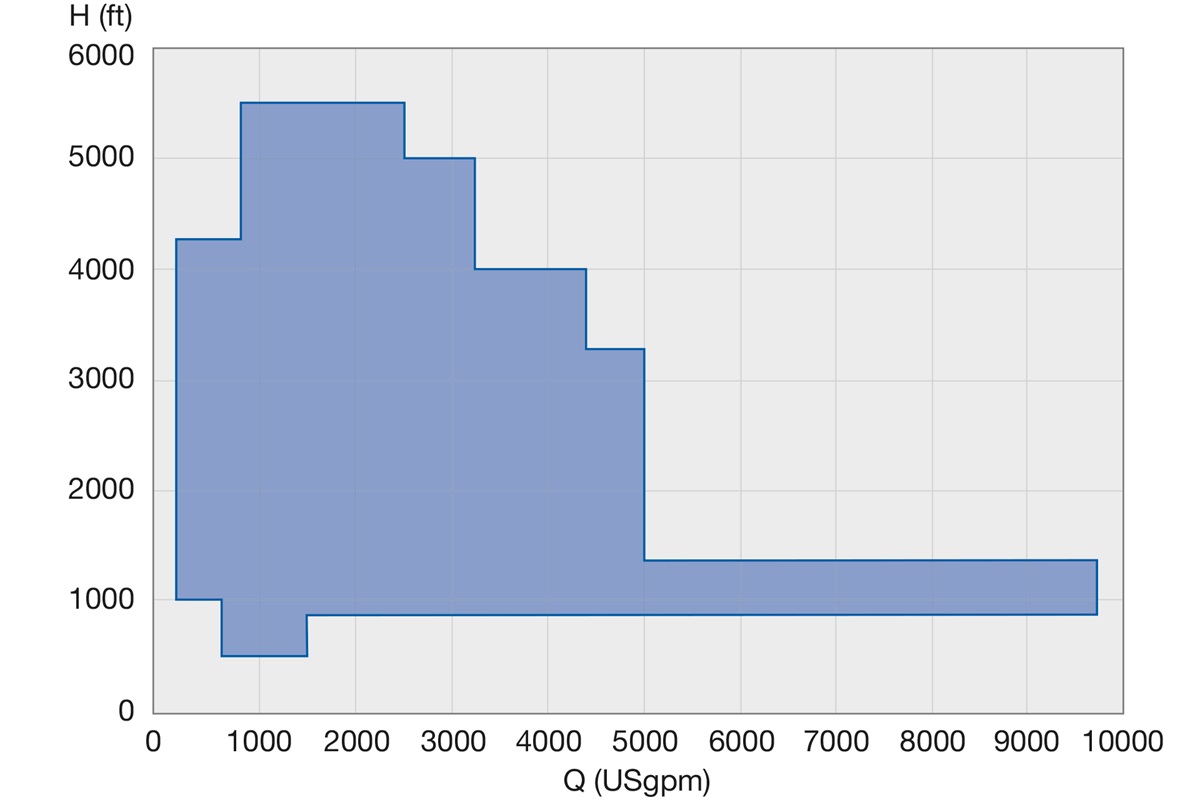

| 50 Hz | 60 Hz | |

| Discharge sizes | up to 350 mm | up to 14 in. |

| Capacities | up to 1,860 m3/h | up to 9,720 US gpm |

| Heads | up to 1,750 m | up to 5,500 ft. |

| Pressures | up to 180 bar | up to 2,610 psi |

| Temperatures | up to 180°C | up to 356°F |

| Pump part | Material |

Suction, stage and discharge casing |

Carbon steel, chrome steel, duplex steel |

| Impellers and diffusers | Carbon steel, chrome steel, duplex steel |

| Shaft | Chrome steel, duplex steel |

| Balancing system | Chrome steel, duplex steel |

Balance drum

The balance drum device carries the major proportion of the hydraulic thrust. The drum diameters are chosen to minimize the thrust at normal operating point. The residual and additional thrust loads occurring above/below the normal operating point are carried by the thrust bearing, typically a taper roller bearing.

The balance drum is suitable for:

- Long life under extreme operating conditions

- Frequent stop-start applications thanks to nearly wear-free device

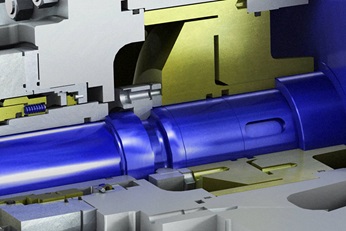

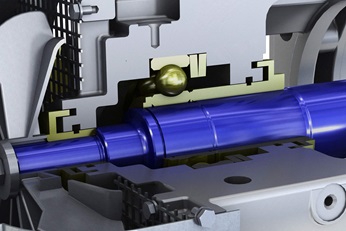

Balance disc

With the balance disc, the axial force is completely compensated, therefore no axial thrust bearing is required.

The disc designs are optimized for each hydraulic and size.

For operation with frequent start and stops, the installation of a lift-off device is available (either mechanical or magnetic).

Mechanical or magnetic (PERMAVORTM) lift-off device

Advantages:

- Prevents touching and wearing of the disc/counter disc during operation at low speed, such as start up and shut down

- Self-controlling passive system

- Reduces load on balance disc under normal operation

- Integrated into the radial bearing housing; no additional power consuming bearings required