- For high vapor and high liquid handling capacity

- No re-entrainment of the mist

The Sulzer KnitMesh V-MISTER™ provides high performance wherever liquid entrainment must be removed from a vertically flowing gas stream.

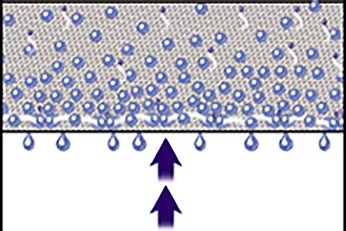

Demisting pads with Sulzer KnitMesh V-MISTER™ technology employ the mechanism of a Von Karman Roll around a bluff body (see figure on top) to obtain high vapor and liquid handling capacity. Here, a vortex develops in a low pressure zone downstream of the channel that has been attached to the bottom of the mesh pad.

Collected droplets deposit in the trough and form a flowing liquid stream there. Contrast this with the standard mesh pad (see figure Sulzer KnitMesh V-MISTER) where a two phase ‘fluidized’ zone of gas and liquid develops in the bottom third to half of the pad, and from which large coalesced droplets must ultimately drain counter-current to the ascending stream.

The high capacity channels of the Sulzer KnitMesh V-MISTER™ shield the collected liquid and then drain it in steady streams, from two sides of the mist eliminator, at the tower periphery where gas velocity is so low that re-entrainment almost never occurs.

This simple enhancement to a standard mesh pad inherently improves mist elimination since the higher velocities that are used increase the droplets’ inertial impaction with the wires or filaments. Meanwhile, the strategically placed collecting channels reduce the liquid hold-up in the drainage zone and hence provide higher operational gas and liquid capacity.

Talk or write to our experts to find your best solution.