-

Submersible drainage pump XJ 25The submersible drainage pump XJ 25 is ideal for pumping water and dirty water mixed with light abrasives. 50 Hz: 2.5 kW. Head max 26 meters, flow max 19 l/s. 60 Hz: 2.9 kW (4 Hp). Head max 30 meters (98 feet), flow max 20 l/s (317 gpm).

-

Submersible drainage pump XJ 40The submersible drainage pump XJ 40 is ideal for pumping water and dirty water mixed with light abrasives. 50 Hz: 3.7 kW. Head max 34 meters, flow max 23 l/s. 60 Hz: 4.3 kW (6 Hp). Head max 36 meters (118 feet), flow max 22 l/s (349 gpm).

-

Submersible drainage pump XJ 50The submersible drainage pump XJ 50 is ideal for pumping water and dirty water mixed with light abrasives. 50 Hz: 5.6 kW. Head max 45 meters, flow max 35 l/s. 60 Hz: 6.7 kW (9 Hp). Head max 49 meters (161 feet), flow max 36 l/s (571 gpm).

-

Submersible drainage pump XJ 80The submersible drainage pump XJ 80 is ideal for pumping water and dirty water mixed with light abrasives. 50 Hz: 8.3 kW. Head max 76 meters, flow max 52 l/s. 60 Hz: 9.8 kW (13 Hp). Head max 94 meters (308 feet), flow max 37 l/s (587 gpm).

-

Submersible drainage pump XJ 110The submersible drainage pump XJ 110 is ideal for pumping water and dirty water mixed with light abrasives. 50 Hz: 11.8 kW. Head max 52 meters, flow max 54 l/s. 60 Hz: 13.5 kW (18 Hp). Head max 63 meters (207 feet), flow max 55 l/s (873 gpm).

-

Submersible drainage center-line pump XJC 50The pump is ideal for pumping water and dirty water mixed with light abrasives. 50 Hz: 5.6 kW. Head max 45 meters, flow max 35 l/s. 60 Hz: 6.7 kW (9 Hp). Head max 49 meters (161 feet), flow max 36 l/s (571 gpm).

-

Submersible drainage center-line pump XJC 80The pump is ideal for pumping water and dirty water mixed with light abrasives. 50 Hz: 8.3 kW. Head max 76 meters, flow max 52 l/s. 60 Hz: 9.8 kW (13 Hp). Head max 94 meters (308 feet), flow max 37 l/s (587 gpm).

-

Submersible drainage center-line pump XJC 110The pump is ideal for pumping water and dirty water mixed with light abrasives. 50 Hz: 11.8 kW. Head max 52 meters, flow max 54 l/s. 60 Hz: 13.5 kW (18 Hp). Head max 63 meters (207 feet), flow max 55 l/s (873 gpm).

-

Submersible sludge pump XJS 25The submersible sludge pump XJS 25 is ideal for pumping sludge and water mixed with solids. 50 Hz: 2.5 kW. Head max 18 meters, flow max 16 l/s. 60 Hz: 2.9 kW (4 Hp). Head max 20 meters (66 feet), flow max 16 l/s (254 gpm).

-

Submersible sludge pump XJS 40The submersible sludge pump XJS 40 is ideal for pumping sludge and water mixed with solids. 50 Hz: 3.7 kW. Head max 24 meters, flow max 20 l/s. 60 Hz: 4.3 kW (6 Hp). Head max 27 meters (89 feet), flow max 20 l/s (317 gpm).

-

Submersible sludge pump XJS 50The submersible sludge pump XJS 50 is ideal for pumping sludge and water mixed with solids. 50 Hz: 5.6 kW. Head max 28 meters, flow max 25 l/s. 60 Hz: 6.7 kW (9 Hp). Head max 31 meters (102 feet), flow max 26 l/s (413 gpm).

-

Submersible sludge pump XJS 80The submersible sludge pump XJS 80 is ideal for pumping sludge and water mixed with solids. 50 Hz: 8.3 kW. Head max 35 meters, flow max 29 l/s. 60 Hz: 9.8 kW (13 Hp). Head max 38 meters (125 feet), flow max 28.5 l/s (452 gpm).

-

Submersible sludge pump XJS 110The submersible sludge pump XJS 110 is ideal for pumping sludge and water mixed with solids. 50 Hz: 11.8 kW. Head max 36 meters, flow max 31 l/s. 60 Hz: 13.5 kW (18 Hp). Head max 40 meters (131 feet), flow max 30 l/s (476 gpm).

Reliable intelligent dewatering

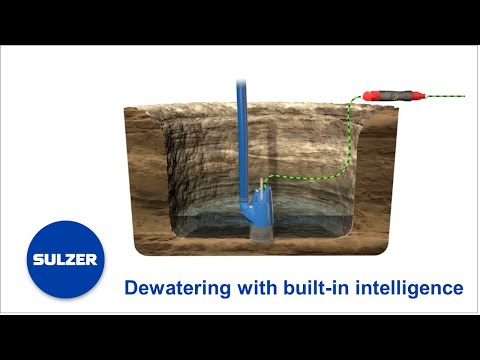

Dewatering pumps with built-in intelligence

Correct motor rotation every time

The AquaTronic unit automatically controls phase order and changes the motor connection to make sure the pump starts with the correct impeller rotation every time. This protects the pump from overheating, saves energy and reduces wear.

No control panels required when the pump is in run mode

The built-in pump electronics eliminate the need for traditional electrical control panels. This increases ease of handling.

Motor protection for safe running

The pump stops if there is a power overload at high amperage, a high temperature in the winding or a missing phase. In this way any crucial failures can be prevented.

Anti-clog function reduces unwanted stops

If the pump fails to start due to a heavy start or a locked rotor, the pump will attempt to free the blocked impeller with backspin and automatic restart.

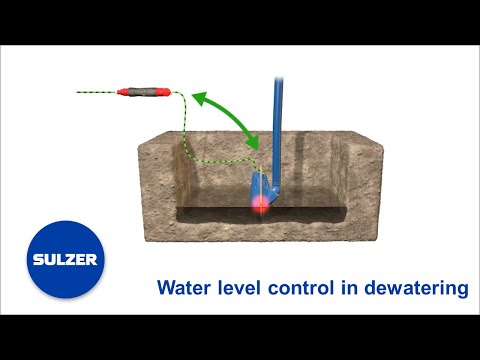

Dewatering pump with AquaTronic and level sensor or float switch

If the pump is also equipped with a level sensor, AquaTronic lowers the power consumption and wear.

- The level sensor and AquaTronic make sure the pump starts and stops at given water levels.

- Energy save mode (energy is saved through stopping at dry run and starting by level sensor)

Dewatering pump with AquaTronic and AquaPlug/AquaTronic control panel

Stop and start the pump easily with the AquaPlug and AquaTronic control panel. Both units provide flashing LED light alarms as well as indications for important parameters for easy and efficient handling.

- Energy save mode is available together with the level sensor

- Service indication light to easily spot alarms

- Automatic restart when power supply problems, such as unbalanced voltage or low/high voltage, are solved

Built-in intelligence with service diagnostics program

Check the pump conditions without disassembly by simply connecting the pump to a PC via a USB cable for access to the service diagnostics program. The program will show the pump data saved in the pump’s built-in memory such as:

Pump status data, pump operating history, pump failure history, pump service/maintenance history, digital manual and spare parts documentation.