Water scarcity

Tackling water scarcity in urban areas

Governments, national, and international institutions, as well as water management companies, are looking for solutions that can address this growing global water demand. As industrial pioneers, Sulzer can work with your water management company to tackle such challenges.

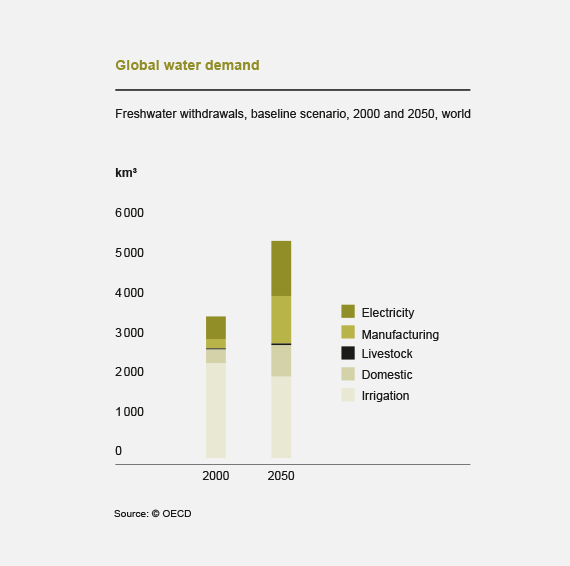

In many regions of the world, the lack of freshwater resources has become a critical concern. Urban populations are growing, which adds to the challenge. Providing access to clean freshwater is critical for a sustainable city life.

Seawater desalination is an important means of providing a sustainable supply of freshwater. Although the clean freshwater is used for different purposes, such as industrial and agricultural processes, 60% is devoted to human consumption. Because energy is the largest single expense for desalination plants, companies are looking for energy-efficient solutions.

Sulzer’s pumps for seawater desalination are market leaders in terms of efficiency. Hence, the company supports its customers in supplying clean freshwater in a cost- and energy-efficient manner.

As market leaders in developing cutting-edge seawater desalination pumps, we are perfectly placed to support your company in supplying clean freshwater in a cost- and energy-efficient manner.

From Seawater to Freshwater: Providing you with effective de-salting solutions

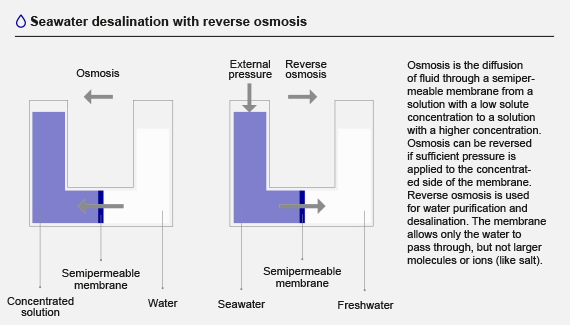

Seawater desalination is a promising and fast-growing solution to combat water scarcity and meet the growing global water demand — see diagram below. Reverse osmosis — a desalination technology — requires less energy and is less expensive than other methods. By providing highly efficient pumps, we can facilitate a supply of freshwater that is affordable and energy-efficient.

There are two main methods for converting seawater into freshwater:

- Desalination technologies based on either thermal processes (such as multiple-effect or multistage flash distillation) or;

- Membrane processes or reverse osmosis — see diagram below.

In the past, thermal desalination technologies have been predominant in the Middle East because the plants are easy to operate and energy costs are low. The current market trend is now turning towards reverse osmosis. Today, due to its unbeatable eco-efficiency, more than two thirds of the newly installed desalination capacity worldwide is based on this technology.

We supply a full range of pumps for sea or brackish water desalination using either reverse osmosis or multiple-effect processes.

To meet growing demands, our company increasingly specializes in further developing and refining our reverse osmosis technology.

Helping you reduce costs of your reverse osmosis plants

Over the years, the efficiency of energy recovery systems has increased which has helped to reduce the life cycle costs of plants. Pumps also play an important role in decreasing operating expenditures.

Since the beginning of the development of desalination applications in the 1980s, we have provided solutions that meet the specific market requirements. In a reverse osmosis plant, multi-purpose high-pressure pumps use 60% of all the energy consumed in the desalination plant. Each single percentage of the efficiency increase lowers the costs of the freshwater production, making your plant more effective and cost-efficient.

Leading pumps made by winning teams

Our teams based out of Finland and Switzerland have developed the new MBN-RO and MSD-RO pump ranges, which are specifically engineered for reverse osmosis applications. These pumps support the efficient production of potable water for residents as well as water for industrial processes.

Thanks to our team’s excellent efforts, the hydraulic efficiency of the pumps have been improved significantly through the optimization of the suction chamber and the design of the impeller, the diffuser, and the volute.

Our leading pumps have already been supplied to several desalination plants in the Middle East and in China. Our installations around the globe support the production of more than three million m3 of freshwater per day.

Thanks to our pump’s advanced hydraulic design, both the MBN-RO and the MSD-RO ranges are the most efficient pumps on the market.

Ensuring efficiency every time

As every kilowatt matters with regard to affordable water supply, our engineers developed highly efficient end-suction process pumps. The SNS process pumps, originally designed for the pulp and paper industry, can be used in auxiliary services in seawater reverse osmosis and other applications in the water market. They achieve top-level efficiency, and they exceed the European Union’s requirements for energy-related products by a significant margin.

These regulations, which aim to reduce energy consumption, specify the minimum efficiency values for water pumps. The minimum efficiency index (MEI) was set at 0.4 as of the beginning of 2015. Around 40% of the water pumps in use do not comply with this regulation. The SNS process pump range — on the market since 2015 — achieved an MEI of 0.7, which is clearly above the required criteria.

Spotting future trends

While regions such as Algeria, Spain, Australia, and the Middle East have built very large plants in the past, the trend is starting to move to small- and medium-sized plants which are easier to construct, install, run, and finance. We can support your small-and-medium-sized plant from a very early project stage by improving the overall efficiency and ensuring the highest possible profitability.

Our dedicated support teams can help you provide an affordable and energy-efficient supply of freshwater.