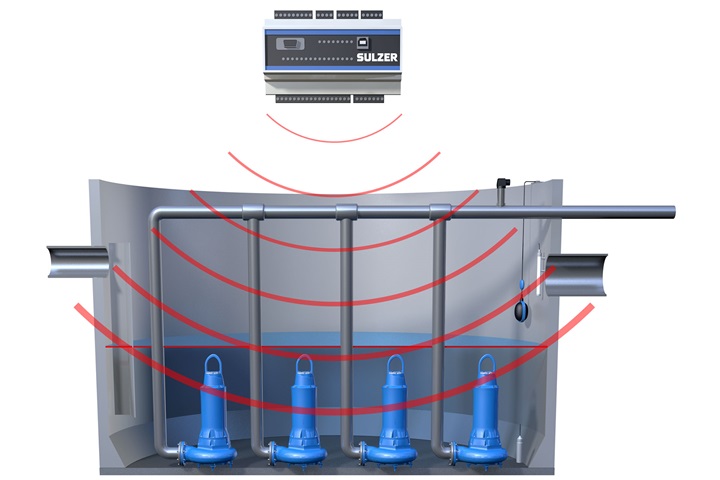

- Operates as a standalone control and monitoring unit

- Minimizes operating costs and energy consumption

- Increases pumping station availability

- Easy to use and configure with built-in operator panel

- Supports all aspects of the LCC (life cycle cost) calculations

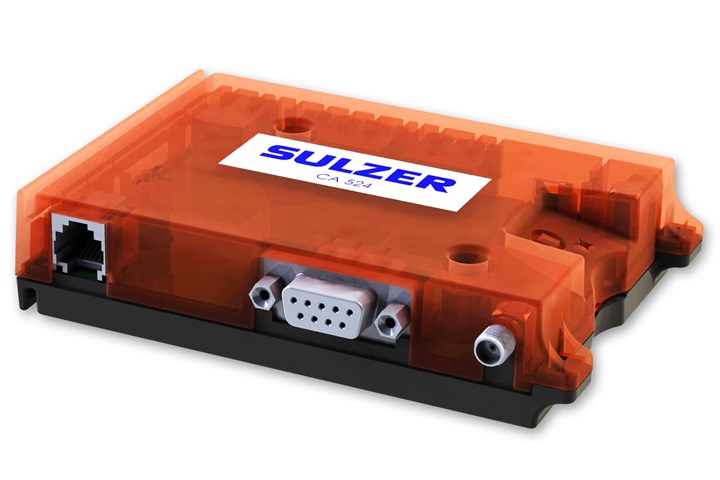

Equipment controller EC 531

Monitoring and control in a single unit

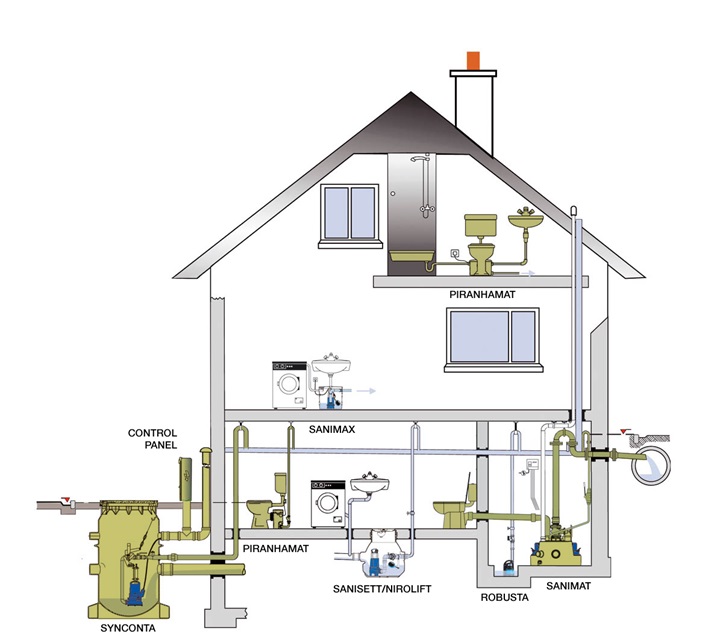

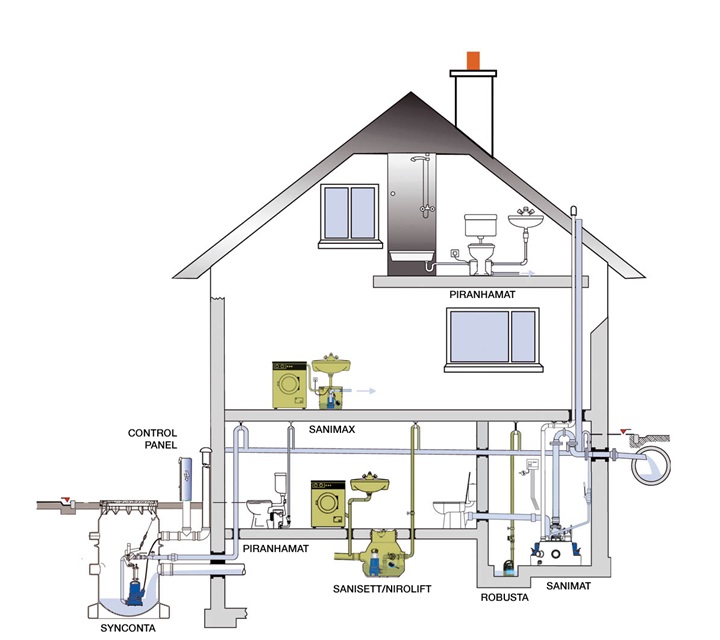

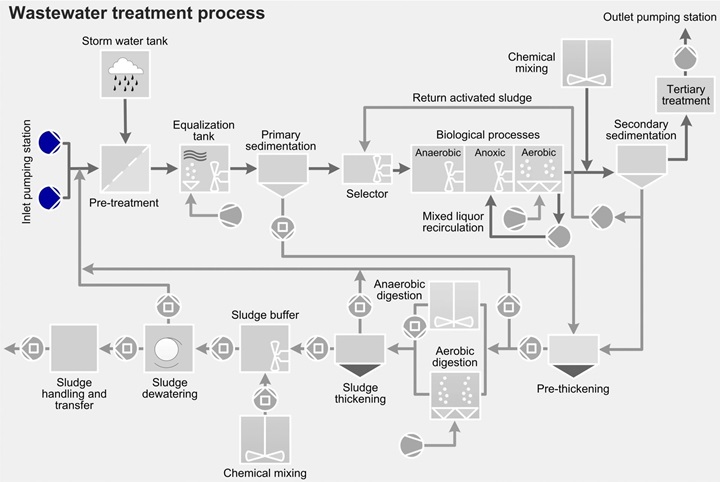

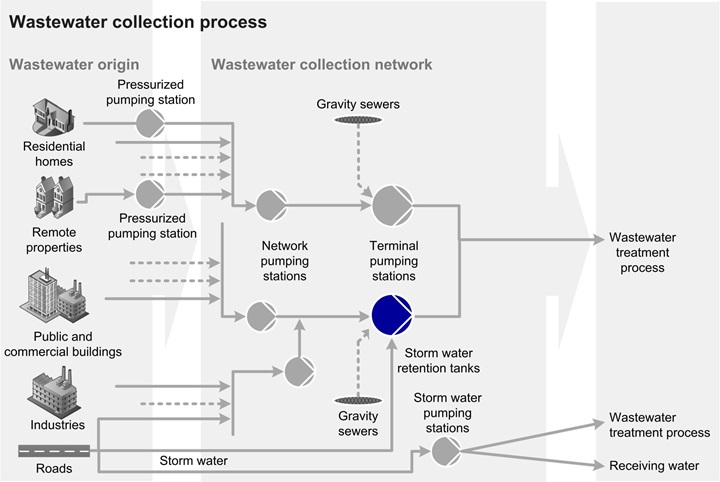

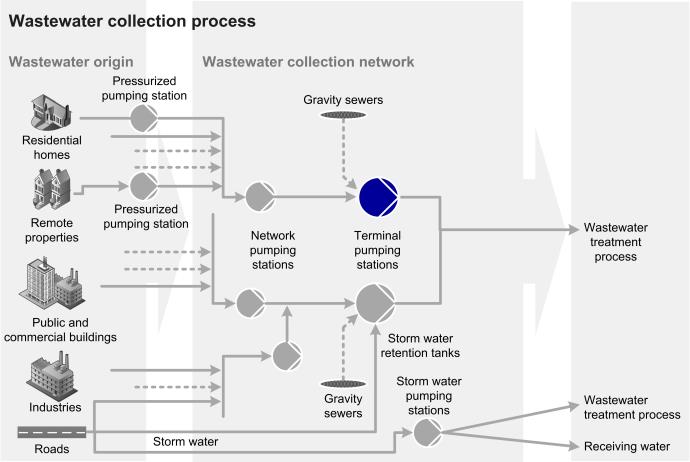

- Monitor and control of municipal wastewater pumping stations

- View alarms, pump status and trends

- Advanced monitoring including crash log functionality

- Manually control pumps and change settings

All functionality you need is integrated into the EC 531 equipment controller. The functionality to help monitor the equipment condition as well as to optimize and reduce risk of overflow, reduce energy costs and cleaning costs etc., is standard. EC 531 gives you instant access to alarms, pump status, level information and trends – both on site and remotely. Functions that help to prevent downtime and flooding are also included.

The equipment controller EC 531 can be used with one or two pumps.

The controller comes with a graphical display offering a full user interface. Level sensing in the pit can be performed using either float switches or a 4-20 mA level sensor.

Communication port RS 485 for sending and receiving information to peripheral products via Modbus interface which gives:

- Less IO needed

- Reduced wiring

- Access to additional data via external devices

- Level set-point, including time delays

- Speed of level change

- Random start levels

- Tariff control

- Maximum runtime

- VFD control logic, including flow calculation, day set points, night set-points and adjustable pump reversal speed

- BEP (best efficiency point)

- Data communication:

Communication via Modbus (RTU / TCP) protocol with other telemetry or SCADA systems

I/O and register cross-reference tables for efficient communication setup

Ethernet communication support

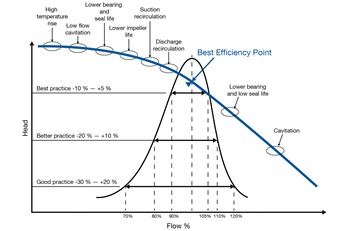

EC 531 has built-in BEP (best efficiency point) control logic functionality. BEP is the point at which the pump operates at peak efficiency. At this point, flow enters and leaves the pump with a minimum amount of flow separation, turbulence and other losses.

Operating the pump closer to its BEP will result in less stress and wear, which increases the reliability and life span of the pump.

At start up, the EC 531 will run a number of capacity-contra-run-frequency calculations to determine the optimum frequency to operate the pumps. This test cycle repeats with a pre-set time interval.

Added value when controlling the pump based on BEP control logic:

- Lower running costs

- Less hydraulic loads on mechanical components

- Less stress on bearing and shaft vibrations

- Less audible noise

- Less suction recirculation, (This also reduces the risk of the pump clogging.)