- Centerline support for reduced thermally induced misalignment

- BBT-D double-suction impeller for low Net Positive Suction Head (NPSH)

- First critical speed is well above operating speed range for smooth operation

- Casing designed for 2x API 610 nozzle loads for freedom from piping distortions

- Grouted or ungrouted, 1x or 2x nozzle load baseplates for reduced installation cost

BBT/BBTD process pump

Two Stage Barrel pumps for the toughest services

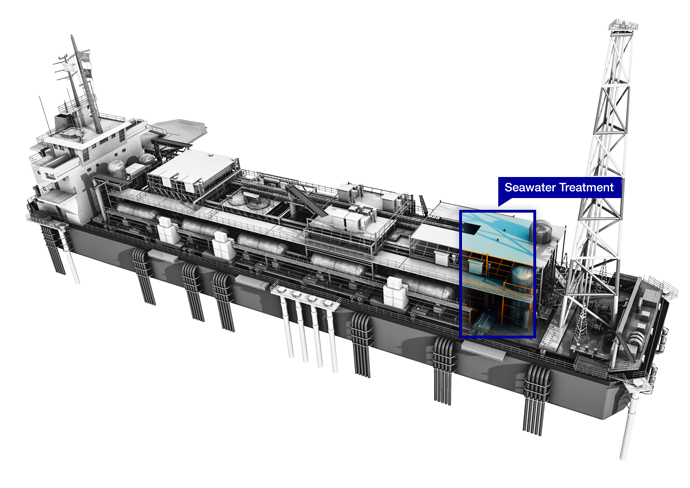

The BBT/BBTD 2 stage, radially split ISO 13709 / API 610 Type BB2 pumps offers the widest range of hydraulic performance in the industry. The BBTD double suction impeller provides reduced NPSH3 for tough services in refineries and other critical applications.

- Unit charge

- Atmospheric or vacuum bottoms retrofits where Net Positive Suction Head Available (NPSHa) is limited

- Fractionator bottoms

- Coker heater charge

- Boiler feed booster

Main design features

- Centerline supported casing with top / top nozzles

- Thermal expansion features

- Staggered-vane double-suction impeller on larger sizes

- Proven coke crusher option

- Metco SUME coatings for abrasion resistance

Key characteristics

| Capacities | Up to 2,300 m3/h / 10,000 US gpm |

| Head | Up to 760 m / 2,500 ft |

| Pressures | Up to 100 bar / 1,450 psi |

| Temperatures | Up to 425 °C / 800 °F |

| Discharge sizes | From 150 to 250 mm / 6 to 10 inches |

| Maximum speed of rotation | Up to 3,600 rpm |

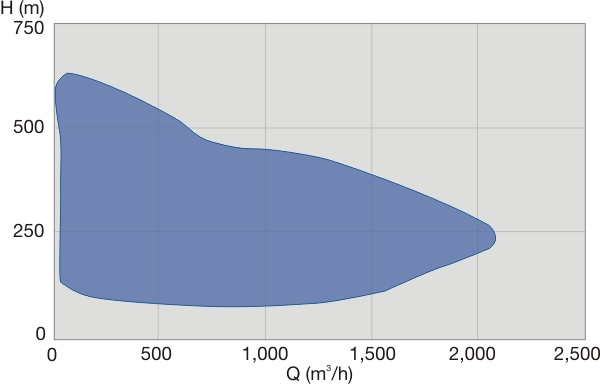

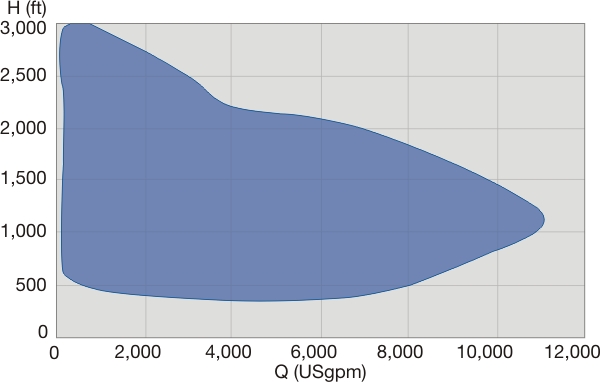

Performance range

Performance range 50 Hz

Performance range 60 Hz